The Advancements of CEE Purlin Metal Track Machines in Modern Construction

In the ever-evolving landscape of modern construction, efficiency and precision have become paramount. One of the critical innovations contributing to these goals is the CEE purlin metal track machine. Designed to streamline the production of CEE purlins, these machines are transforming how builders approach structural frameworks, combining speed, accuracy, and versatility.

What is a CEE Purlin?

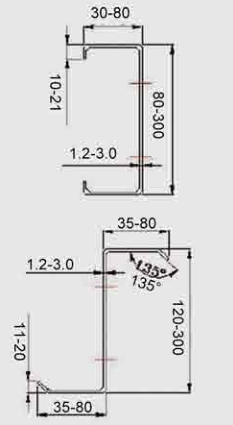

Before delving into the intricacies of the manufacturing machine, it's essential to understand what a CEE purlin is. CEE purlins are horizontal beams used in the roofing and siding of buildings, particularly in steel-framed structures. They are typically made from cold-formed steel and are characterized by their 'C' shape, which provides excellent load-bearing capacity while minimizing weight. Their design allows for easy installation, making them a popular choice in various construction projects, including warehouses, factories, and agricultural buildings.

The Role of Metal Track Machines

The CEE purlin metal track machine automates the production of these essential structural components. Traditional methods of manufacturing purlins can be labor-intensive and time-consuming, often leading to inconsistencies in quality and dimensions. In contrast, modern metal track machines employ advanced technology to enhance productivity and accuracy.

These machines utilize computer numerically controlled (CNC) systems that enable precise cutting, punching, and bending of metal sheets. The process begins with rolled steel being fed into the machine, where it is shaped into the CEE profile. This automation reduces human error, ensuring that each purlin meets the specified tolerances for strength and stability.

Key Benefits of CEE Purlin Metal Track Machines

1. Increased Production Speed One of the most significant advantages of CEE purlin metal track machines is their speed. Automated production lines can produce large quantities of purlins in a fraction of the time traditional methods would require. This rapid output is crucial in meeting project deadlines and reducing labor costs.

2. Consistent Quality With CNC technology, every purlin produced is identical, ensuring uniform quality across all components. This consistency is vital for structural integrity, as even minor discrepancies can affect the overall stability of a building.

3. Cost-Effectiveness While the initial investment in a CEE purlin metal track machine may be substantial, the long-term savings are undeniable. The reduction in labor costs, coupled with the increased production rate, allows companies to maximize their profitability. Furthermore, the precision of these machines minimizes material waste, further enhancing their cost-efficiency.

4. Versatility CEE purlin machines can often be adjusted to produce various profiles and sizes, accommodating the changing needs of construction projects. This versatility is invaluable in an industry where customization is frequently required.

5. Enhanced Safety Automated machines reduce the need for manual handling and labor, which can lead to workplace injuries. By minimizing human involvement in potentially hazardous operations, these machines contribute to a safer working environment.

Conclusion

The integration of CEE purlin metal track machines into the construction industry is a testament to the advancements in manufacturing technology. These machines not only enhance efficiency but also ensure that the structural components produced are of the highest quality. As the demand for robust and cost-effective building solutions continues to grow, the role of CEE purlin metal track machines will undoubtedly become more significant. Embracing this technology allows construction companies to remain competitive in a fast-paced industry, ultimately contributing to the creation of safer, more durable structures for the future.

By investing in CEE purlin metal track machines, builders are not just keeping pace with modern demands; they are setting the foundation for innovative approaches to construction, one purlin at a time.