The galvanized steel cable tray roll forming machine stands as an epitome of modern industrial efficiency, carving its niche in the production of robust cable management systems. As industries expand and the demand for structured cabling systems grows, the significance of an advanced roll forming machine becomes apparent.

Industrial experience unveils that these machines are nothing short of revolutionary. They have intricately woven themselves into the fabric of manufacturing processes, offering unparalleled precision and efficiency.

Picture a sprawling factory where cable trays are produced. It's bustling with activity, yet there's a seamless flow, an orchestration made possible by the intelligent integration of these roll forming machines. Such environments showcase how these machines elevate production capabilities, ensuring consistent quality while minimizing manual intervention.

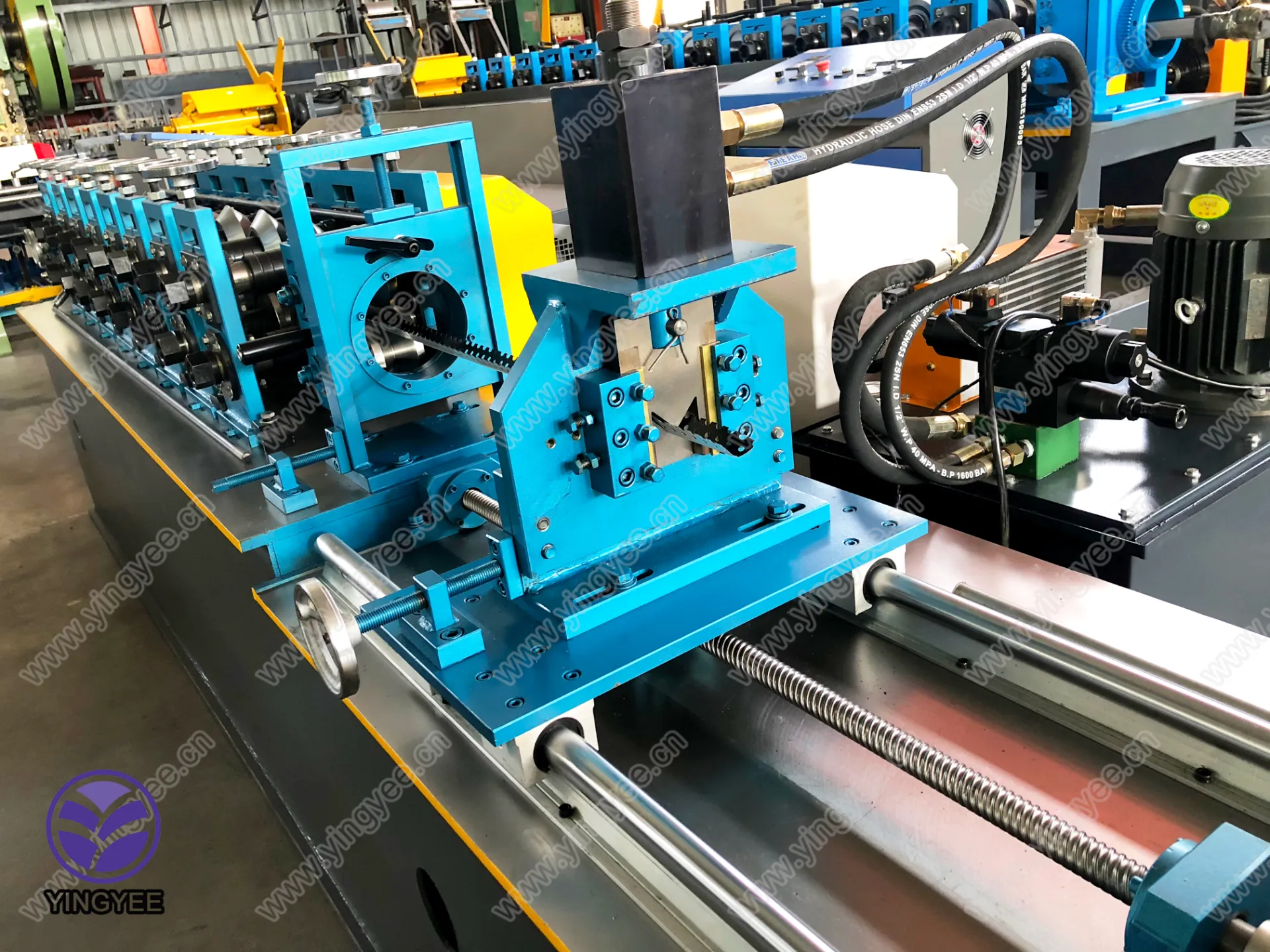

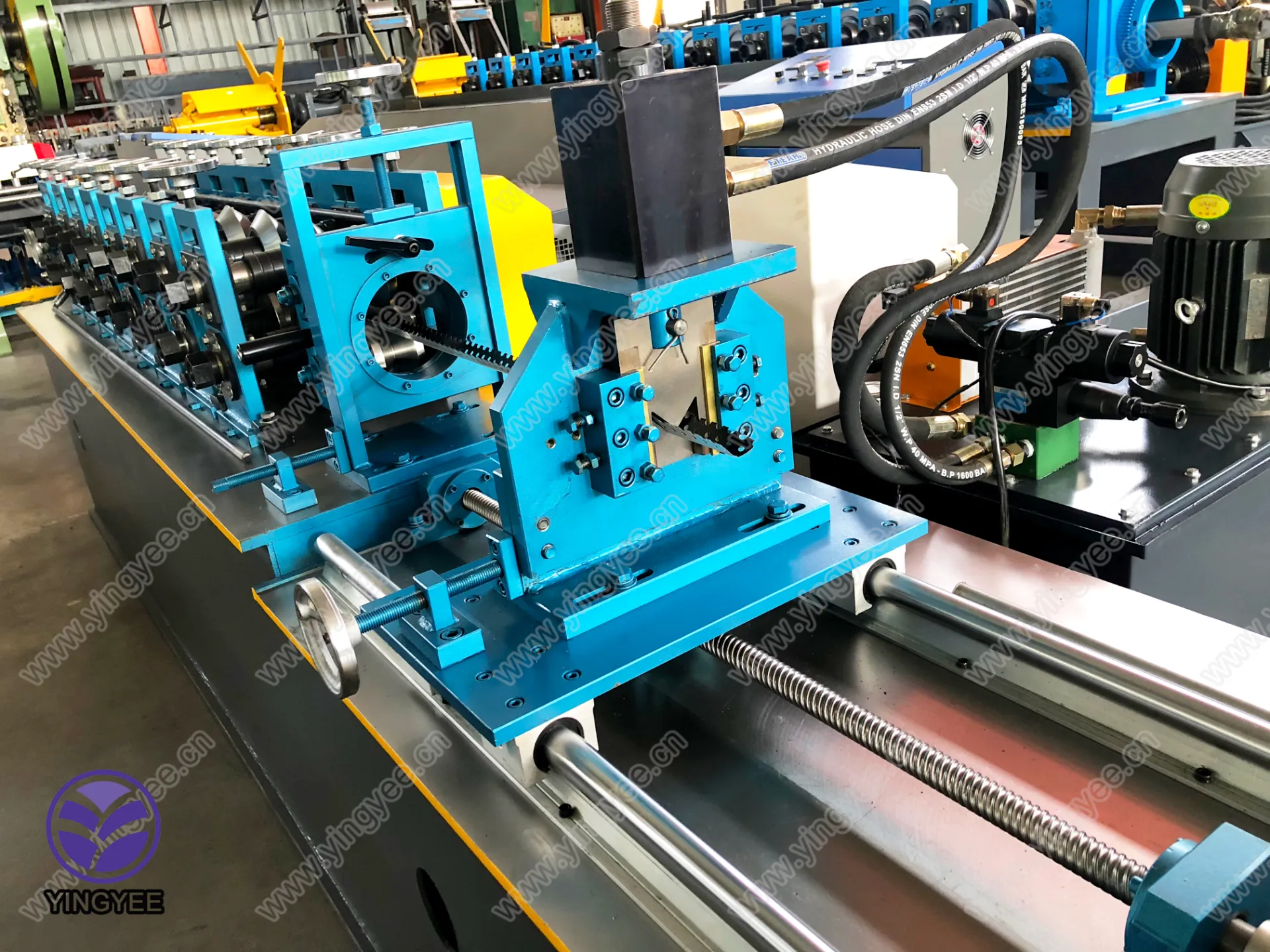

From an expertise standpoint, delving deeper into the machinery reveals a blend of intricate mechanics and advanced technology. A galvanised steel cable tray roll forming machine starts with loading steel coils, which are meticulously unwound and guided through a series of rollers designed precisely to shape the metal. The machinery’s precision engineering ensures that each tray meets specific dimensional standards, crucial for safety and operational functionality in electrical setups. The galvanization process precedes this forming operation, providing additional corrosion resistance, which is indispensable in protecting delicate cabling from environmental factors.

Professional experts have dedicated years to mastering the complexities of these machines. Their authoritative insights stem from understanding every nuance—from the initial setup to the adjustments required for different steel gauges and tray sizes. These experts emphasize machine maintenance and calibration, highlighting that regular inspection and upkeep are vital in averting unforeseen downtimes and ensuring an optimal production lifecycle.

galvanized steel cable tray roll forming machine

Trustworthiness associated with a galvanized steel cable tray roll forming machine is derived from its reliability and the safety it offers. Manufacturers invest heavily in ensuring these machines meet stringent industry standards. Certifications from reputable industry bodies further reinforce their credibility, ensuring that end products adhere to both national and international safety norms. These measures resonate confidence among manufacturers and consumers alike, reinforcing trust through demonstrated performance and compliance.

Moreover, real-world case studies amplify understanding of how these machines transform production landscapes. Consider a corporation that transitioned from manual tray fabrication to implementing automated roll forming machines. The result was a staggering increase in production efficiency by 50%, complemented by a notable enhancement in the consistency of product quality. These tangible metrics underscore the pivotal role roll forming machines play in scaling operations while maintaining rigorous quality standards.

To wrap things up, the narrative around galvanized steel cable tray roll forming machines is not just about mechanization. It's a testament to industrial evolution, championing precision, efficiency, and reliability. As businesses pivot towards smarter, more sustainable practices, these machines emerge as cornerstone innovations, bridging the gap between traditional methodologies and future-forward production technologies. Their integration presents a compelling proposition for forward-thinking manufacturers, eager to harness cutting-edge technology for superior cable management solutions.