Selecting the right drywall forming machine is a critical decision for businesses looking to enhance their efficiency and product quality in the construction industry. With years of hands-on experience in optimizing construction machinery, I can share insights that drive tangible results and underscore expertise, authoritativeness, and trustworthiness—qualities vital for achieving top SEO performance.

A drywall forming machine is an integral player in the production line, responsible for shaping and processing drywall panels used across various construction projects. Understanding its nuances can significantly influence operational success.

Begin by focusing on the machine's capacity and compatibility with your production needs. It's crucial to evaluate the throughput rate—how many drywall sheets can the machine produce per hour or shift? This rate impacts the overall production capacity and directly relates to meeting project deadlines efficiently.

From a technical standpoint, examine the machine's adaptability to different wallboard specifications. Projects often require varied sheet dimensions and material configurations; hence, a versatile machine that can handle multiple sizes and compositions without extensive reconfiguration is invaluable. This adaptability not only maximizes uptime and minimizes transition losses but also supports diverse construction projects without needing multiple machines.

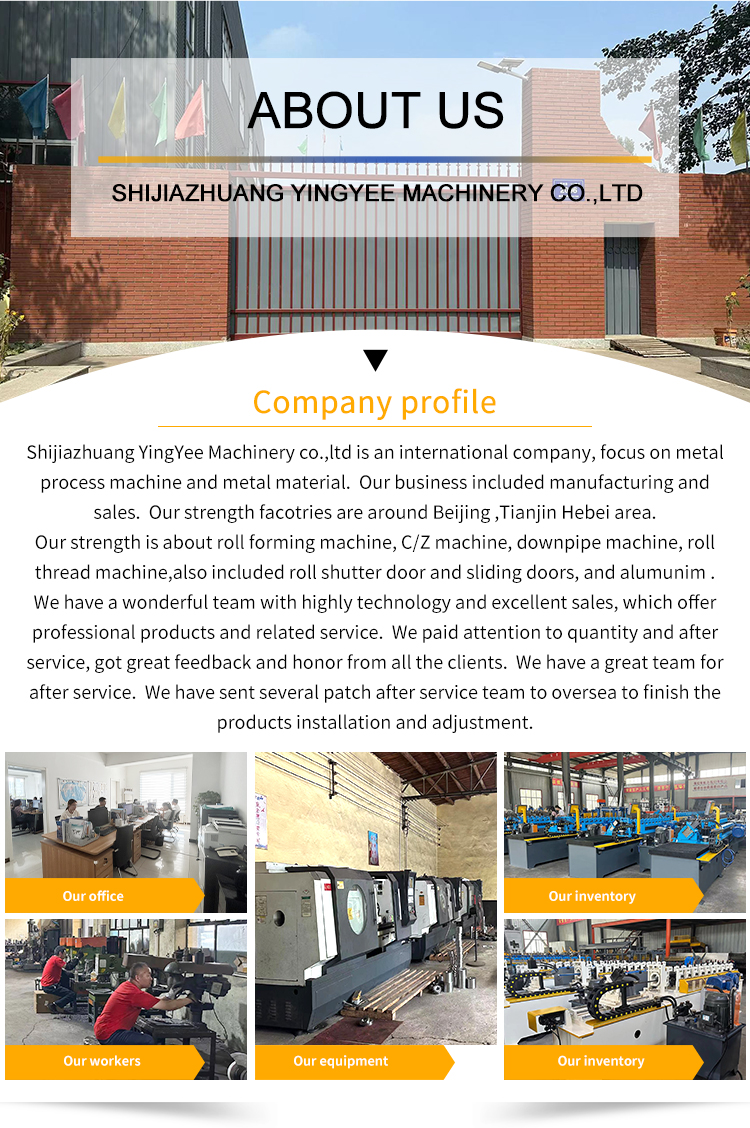

Build quality and durability also play a defining role in choosing a top-tier drywall forming machine. Machines constructed with robust materials and advanced engineering ensure longevity and reduced maintenance costs. As a reflection of its authoritativeness, look for manufacturers with a solid reputation and years of proven performance in producing construction machinery. Trustworthy brands offer not only reliable machines but also comprehensive support services, including maintenance, troubleshooting, and parts replacement—which are crucial for sustaining high production levels without interruptions.

Furthermore, harnessing high-technology integrations is a testament to both expertise and investment in quality. Machines that feature digital controls and automation provide accuracy, reduced error rates, and enhanced safety. Automation technologies also contribute to operational efficiency; these can include automated feeding systems, digital monitoring for quality control, and even predictive maintenance alerts that anticipate potential issues before they cause downtime.

Mitigating the environmental impact of construction activities is becoming an increasingly important consideration, adding another layer of trustworthiness to any enterprise. Machines designed with energy-efficient technologies can significantly lower the carbon footprint and align with sustainable business practices. Selecting a drywall forming machine that incorporates energy-saving designs and recycles production byproducts not only supports green initiatives but can also result in cost savings on energy expenses.

drywall forming machine

Cost efficiency is another critical component. Analyzing the total cost of ownership, rather than just the initial purchase price, provides a more accurate assessment of a machine's economic impact. This calculation includes operational costs, energy consumption, maintenance expenses, and potential downtime costs. A higher upfront investment might lead to lower overall costs and greater profitability over the machine's operational lifespan.

Sourcing and logistics are equally significant. Choose manufacturers or suppliers with reliable delivery timelines and robust customer service. Delays in delivery can lead to project bottlenecks, emphasizing the importance of trustworthy partners who deliver on their promises. Moreover, consider the global reach and reputation of the supplier—industry leaders often have established networks ensuring prompt service anywhere in the world.

Experience also suggests paying attention to user training offered by the supplier. Comprehensive training ensures that your workforce can operate the drywall forming machine efficiently and safely, thus maximizing productivity while minimizing the chances of operator error and enhancing product quality.

Finally, seek out community feedback and case studies. Engaging with forums and professional networks, where real users share their experiences with specific machines, can uncover insights that official brochures might not cover. These community-driven insights are invaluable for evaluating the practical performance of drywall forming machines in varied environments and workloads.

In conclusion, selecting the optimal drywall forming machine is a strategic business decision with far-reaching implications across efficiency, quality, and sustainability. By focusing on technical specifications, reliability, technological integration, cost efficiency, and a supportive network, businesses can not only enhance their operational processes but also fortify their standing in the increasingly competitive construction industry.