In the burgeoning field of renewable energy, the solar industry has seen tremendous growth. Central to efficient solar system installation is the solar strut profile roll forming line, a specialized piece of machinery that plays a pivotal role in the manufacturing process. This article delves into its nuances, underscoring the machinery's expertise, authority, and trustworthiness in solar infrastructure production.

To truly appreciate the value of a solar strut profile roll forming line, understanding its functionality is essential. At its core, this machinery automates the transformation of raw material metal coils into precisely fabricated solar strut profiles. These profiles serve as the backbones of solar panel installations, ensuring structural integrity and alignment. The reduction in manual labor and time consumption presents a significant leap in manufacturing efficiency.

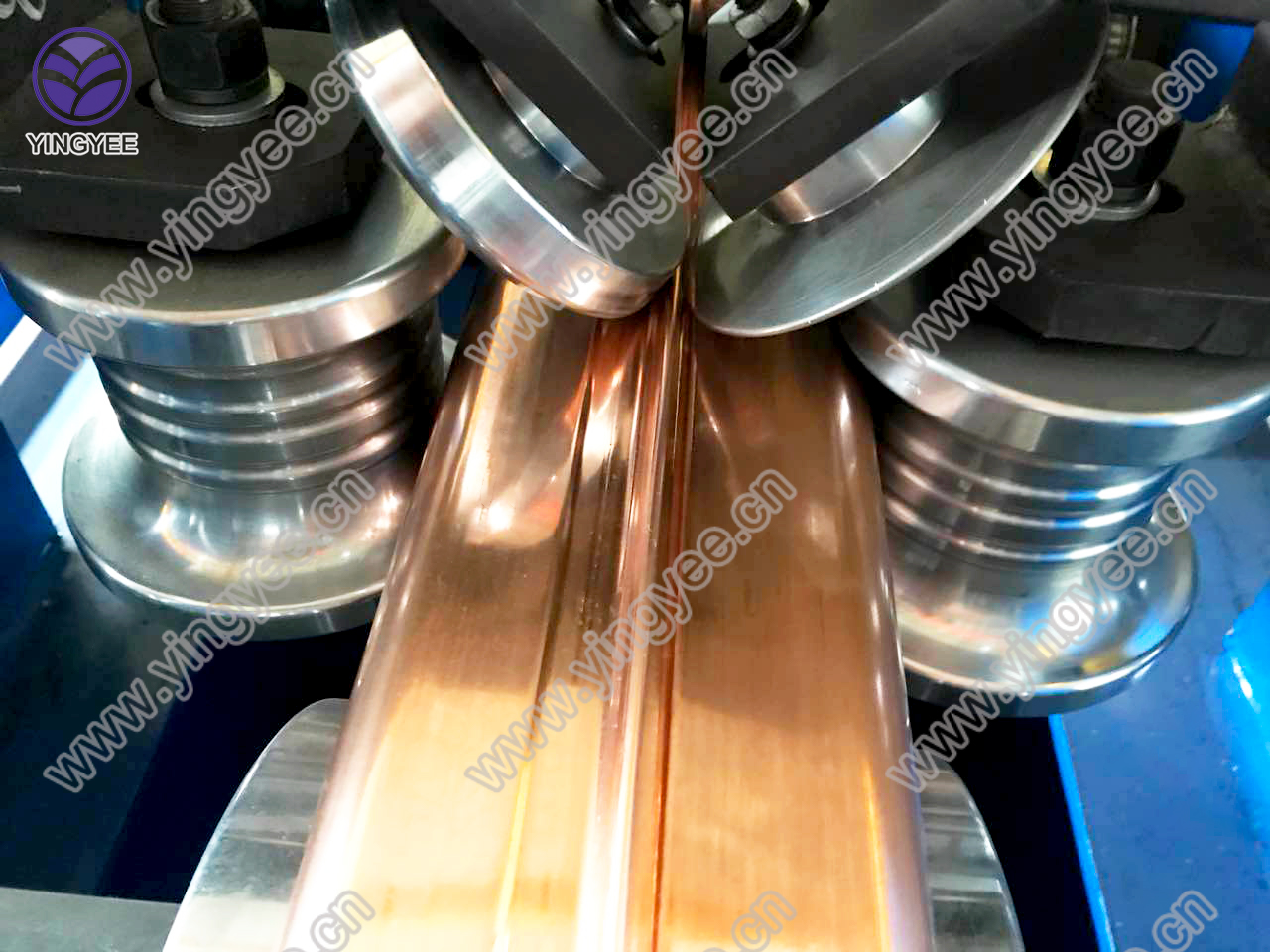

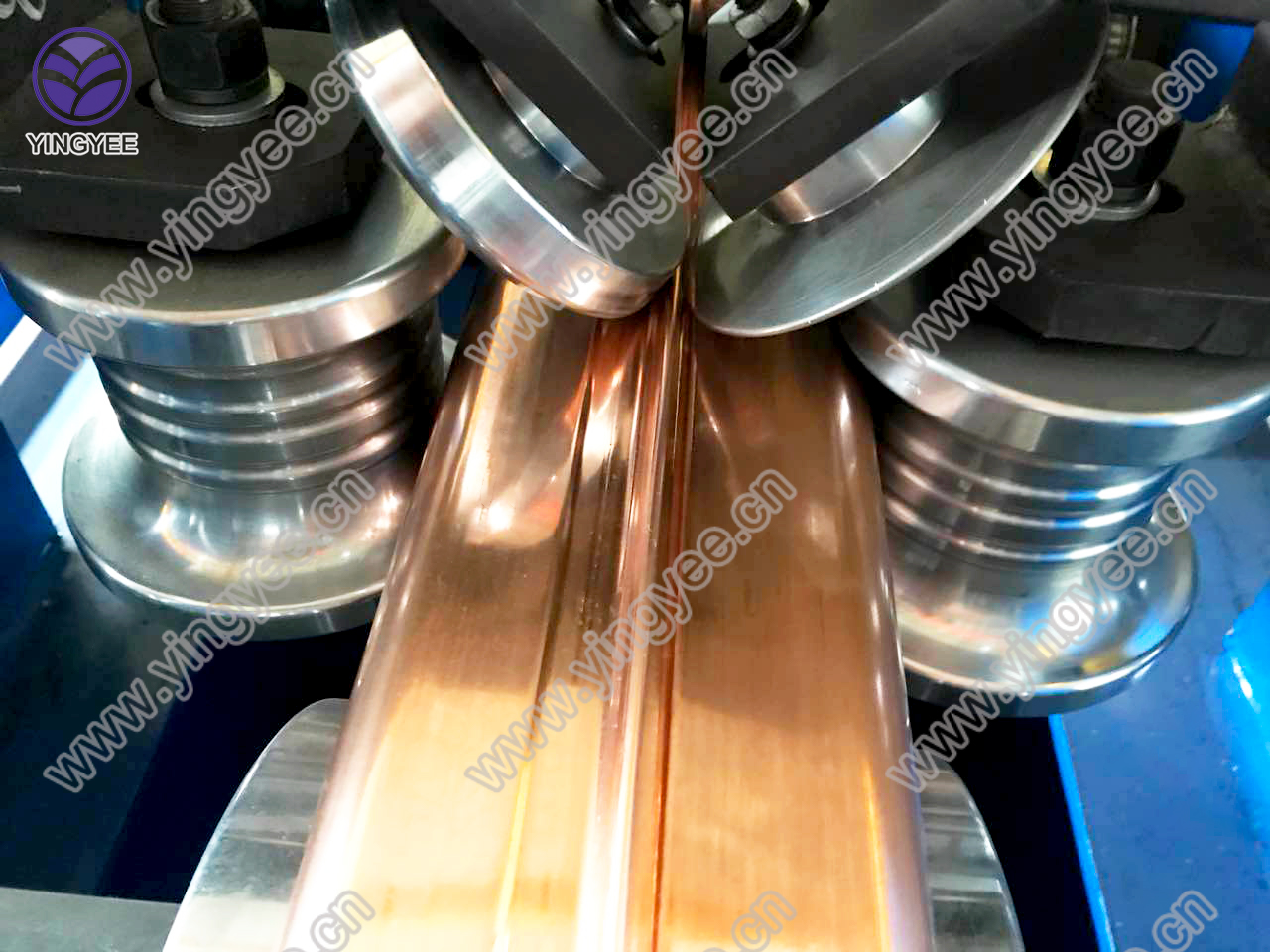

The design of the roll forming line is a testament to engineering excellence. Comprising sequential sets of precisely engineered rollers, the machine guides metal through a carefully controlled process. Each roller sequence performs specific bending, cutting, and punching actions, ensuring the end product meets stringent industry standards. This precision not only guarantees the durability of solar infrastructure but also impacts the energy output efficiency by providing optimal support for solar modules.

Producers of solar strut profile roll forming lines continuously innovate, emphasizing expertise in high-quality material selection and cutting-edge technological integration. This commitment guarantees that products cater to diverse climate conditions and operational demands. Companies invest heavily in R&D to maintain their competitive edge, demonstrating leadership in advancing solar technology.

The authority of a manufacturer is often showcased through certifications and collaborations with leading industry bodies. For instance, adherence to ISO standards and partnerships with energy commissions underscore a company’s commitment to excellence and safety. By aligning with these standards, manufacturers provide assurance to their clients about the reliability and quality of their products. Furthermore, customer testimonials and case studies from established solar energy companies employing these roll forming lines reinforce the manufacturer's reputation.

solar strut profile roll forming line

In a market inundated with varied options, trustworthiness becomes a critical criterion for choosing the right equipment. A transparent supply chain, robust warranty policies, and responsive after-sales service are vital aspects that establish a trust dynamic between manufacturers and clients. Companies that prioritize these elements see increased customer loyalty and long-term partnerships. Moreover, machine adaptability to newer technologies and solar innovations ensures that clients remain at the forefront of sustainable technology without frequent overhauls of their machinery.

From an environmental perspective, the efficiency of a solar strut profile roll forming line contributes indirectly to a reduction in carbon footprint associated with solar panel production. Efficient machines mean less energy consumption during manufacturing, aligning with broader goals of sustainability and environmental responsibility. For stakeholders in the energy sector, this synergy between machine efficiency and environmental consciousness adds another layer of credibility to the manufacturer.

The demand for renewable energy sources continues to surge globally, and with it, the need for reliable solar infrastructure components. The solar strut profile roll forming line is not just a piece of machinery but an emblem of quality, innovation, and reliability in the renewable energy industry. Its design and application reflect a higher understanding of industry needs and a commitment to advancing solar technology, ensuring that solar installations remain robust, efficient, and at the cutting edge of technology.

Manufacturers in this sector, by cultivating experience, demonstrating expertise, establishing authority, and proving trustworthiness, not only enhance their reputation but also fortify the foundation upon which the solar energy sector rests. Consequently, solar strut profile roll forming lines stand as indispensable assets in realizing a sustainable and energy-efficient future.