- Understanding the Importance of Gutter Downspout Machines

- Key Features of Modern Gutter Downspout Roll Forming Machines

- Data-Driven Insights: Market Demand for Gutter Downspout Equipment

- Technical Advantages: How Advanced Machines Outperform Competitors

- Manufacturer Comparison: Choosing the Right Supplier

- Custom Solutions for Diverse Production Requirements

- Real-World Applications: Success Stories with Gutter Downspout Machines

(gutter downspout machine for sale)

Understanding the Importance of Gutter Downspout Machines

Gutter downspout machines are essential for manufacturing durable and precise rainwater management systems. These machines streamline the production of gutter components, ensuring uniformity and structural integrity. With urbanization driving demand for efficient drainage solutions, investing in a high-quality gutter downspout machine for sale

becomes critical for contractors and manufacturers aiming to meet industry standards.

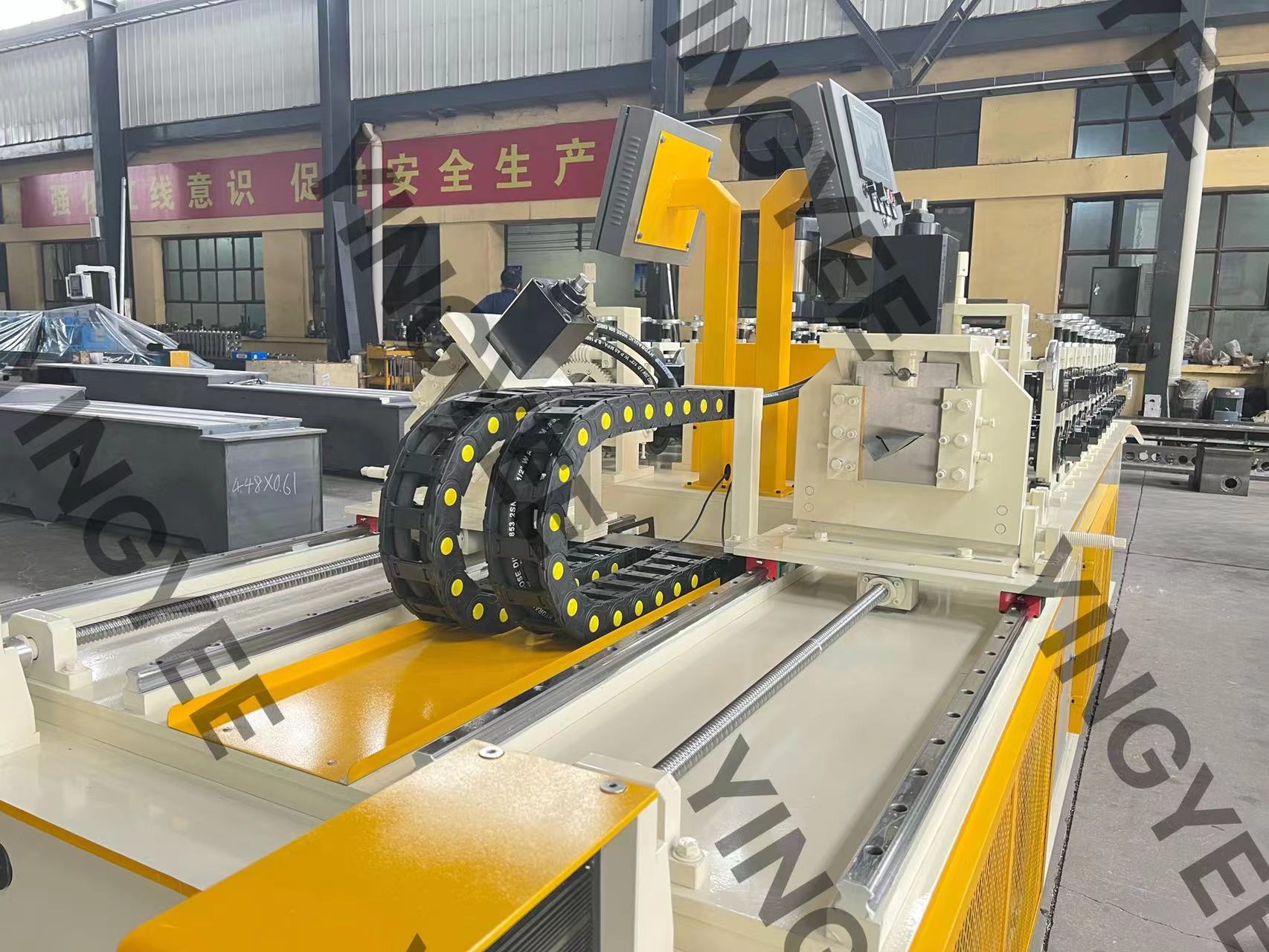

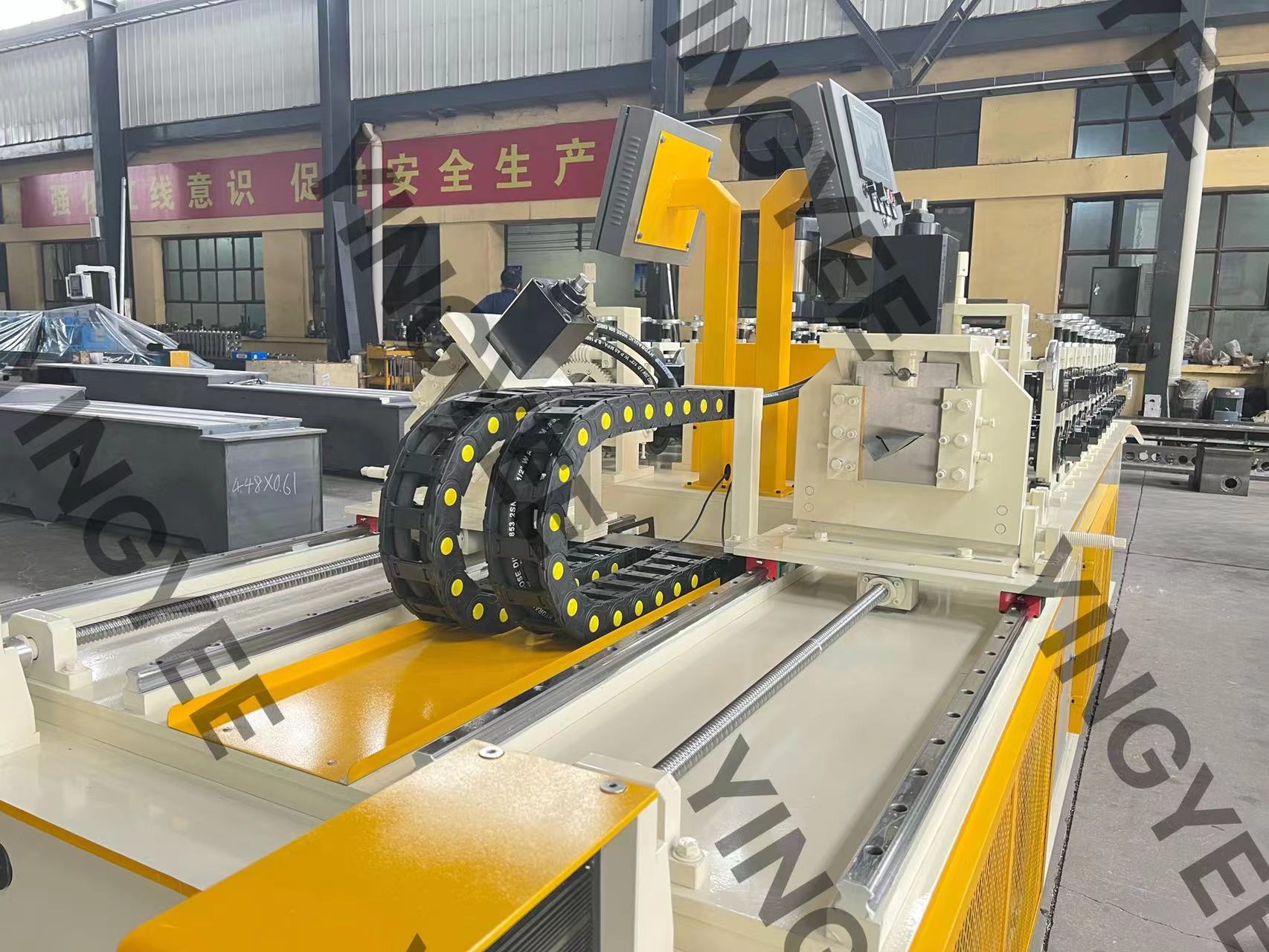

Key Features of Modern Gutter Downspout Roll Forming Machines

Modern gutter downspout roll forming machines integrate automation, precision engineering, and material versatility. Key features include:

- Adjustable roll-forming speeds (up to 25 meters per minute)

- Compatibility with galvanized steel, aluminum, and copper

- PLC-controlled operations for consistent output

- Energy-efficient motors reducing power consumption by 30%

Data-Driven Insights: Market Demand for Gutter Downspout Equipment

The global gutter machinery market is projected to grow at a CAGR of 5.8% through 2030, driven by infrastructure development and climate-resilient construction. A 2023 industry report highlighted that 68% of contractors prioritize machines with dual-purpose capabilities (gutters and downspouts), emphasizing the need for multifunctional roll-forming systems.

Technical Advantages: How Advanced Machines Outperform Competitors

Advanced gutter downspout machines leverage servo-driven technology and modular designs to minimize material waste. For instance, the latest models reduce scrap rates by 22% compared to traditional systems. Additionally, integrated quality sensors detect deviations in real-time, ensuring 99.5% dimensional accuracy across production batches.

Manufacturer Comparison: Choosing the Right Supplier

| Manufacturer |

Production Speed (m/min) |

Material Thickness Range (mm) |

Warranty Period |

Price Range (USD) |

| AlphaForm |

20-25 |

0.3-1.2 |

3 years |

$45,000-$65,000 |

| BetaRoll |

18-22 |

0.4-1.0 |

2 years |

$38,000-$58,000 |

| GammaTech |

25-30 |

0.3-1.5 |

5 years |

$62,000-$85,000 |

Custom Solutions for Diverse Production Requirements

Leading suppliers offer tailored configurations, such as hydraulic punching units or powder-coated finish modules. For example, a U.S.-based manufacturer increased output by 40% after retrofitting their gutter downspout machine with a laser-guided cutting system. Customizable options include:

- Variable flange heights (100-200mm)

- Tool-free mold changes for rapid product switching

- IoT-enabled performance monitoring

Real-World Applications: Success Stories with Gutter Downspout Machines

A European construction firm reported a 50% reduction in installation time after adopting GammaTech’s gutter downspout roll forming machine. Similarly, a Canadian roofing company achieved ROI within 14 months by automating their downspout production line. These cases demonstrate why selecting a robust gutter downspout machine for sale remains a strategic investment for sustainable growth.

(gutter downspout machine for sale)

FAQS on gutter downspout machine for sale

Q: What factors affect the price of a gutter downspout machine for sale?

A: Pricing depends on production capacity, automation level, and customization options. Higher-speed models with advanced controls typically cost more. Material thickness compatibility also influences the final price.

Q: How does a gutter downspout roll forming machine work?

A: It feeds coiled metal through rollers to shape gutter downspouts in a continuous process. The machine automatically cuts formed sections to preset lengths. Hydraulic systems ensure precision for consistent product quality.

Q: What maintenance do gutter downspout machines require?

A: Regular lubrication of rollers and cutting blades is essential. Electrical components need dust protection and periodic inspection. Annual professional servicing helps maintain optimal performance.

Q: Can these machines produce different downspout sizes?

A: Yes, most models allow quick die changes for various dimensions like 2"x3" or 3"x4" downspouts. Some advanced machines feature adjustable rollers for size flexibility. Always verify capacity with manufacturers for specific requirements.

Q: What safety features do modern gutter downspout machines include?

A: Standard features include emergency stop buttons and protective guards. Many models have infrared sensors to prevent hand-entrapment risks. Some offer automatic shutdown for overheating or power fluctuations.