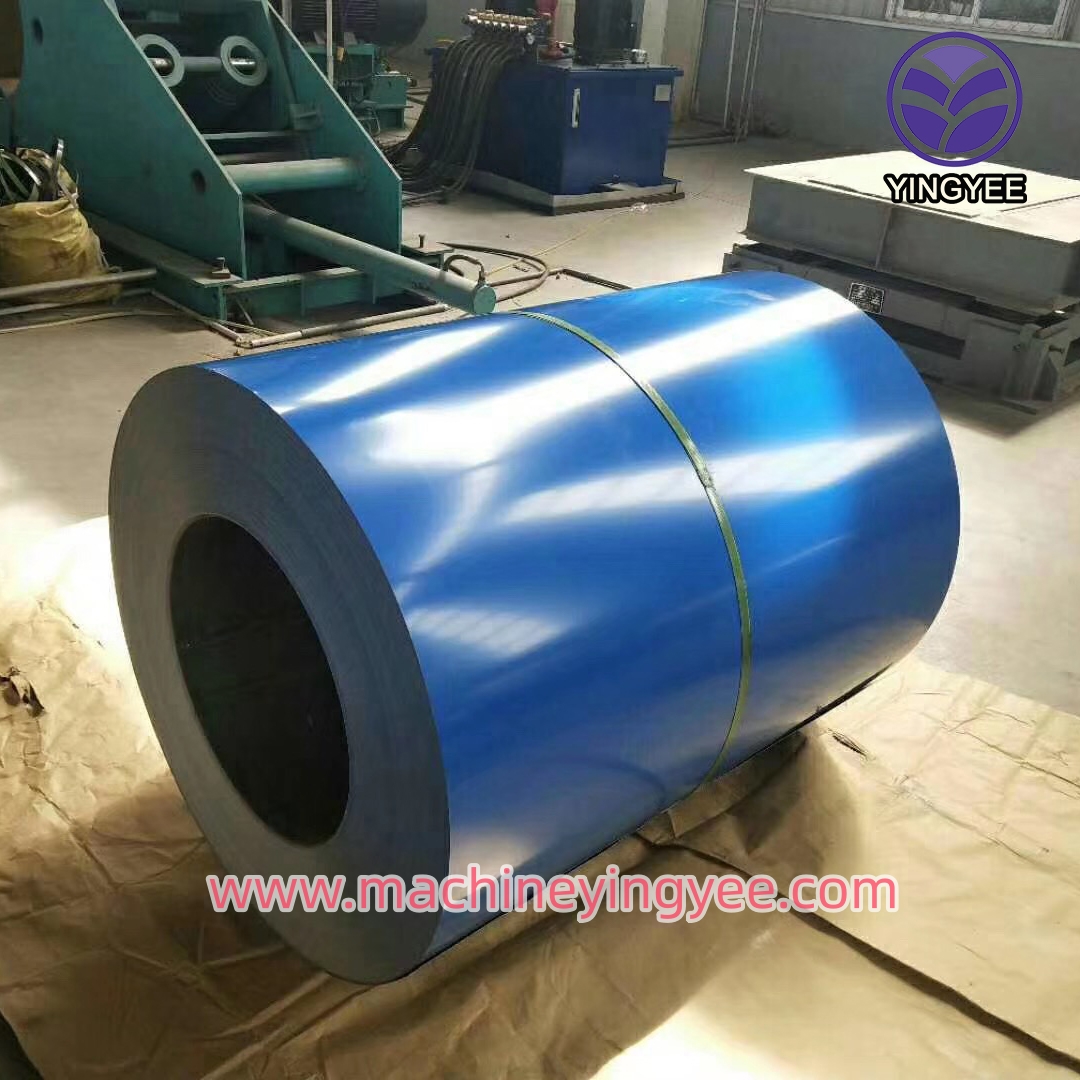

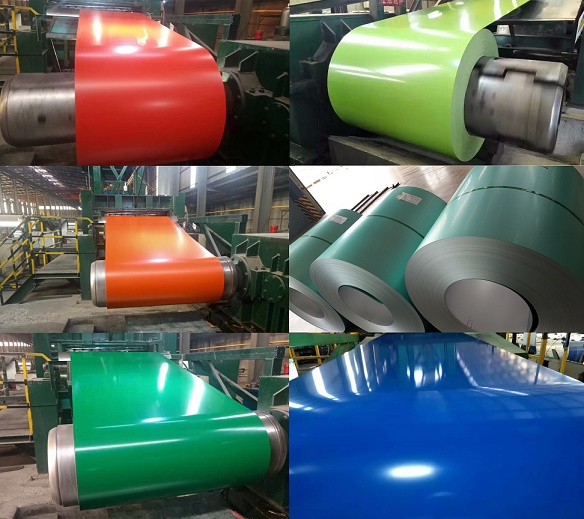

In today's construction and manufacturing industries, materials must deliver both lasting performance and aesthetic appeal. YingYee Machinery's PPGI (Pre-Painted Galvanized Iron) Coils represent the perfect fusion of these essential qualities. Our advanced coating technology transforms ordinary galvanized steel into vibrant, long-lasting building materials that stand up to the toughest environmental challenges while maintaining their visual brilliance for decades.

The secret behind our PPGI Coils lies in the sophisticated multi-layer protection system. Starting with a high-quality galvanized base (Z60-Z275 coating weight), we apply a chromate conversion layer before finishing with premium PVDF or polyester coatings from world-leading chemical suppliers. This combination delivers exceptional weather resistance, corrosion protection, and color retention. Available in over 200 standard colors with custom color matching capabilities, our coils meet the most demanding architectural specifications while complying with international standards including ASTM, EN, and JIS.

Ние доставяме множество материали, включително поцинковани намотки, предварително боядисани намотки, стоманени ленти, алуминиеви цинкови намотки, алуминиеви намотки и др.

When appearance and durability matter equally, professionals consistently choose YingYee's PPGI Coils for three compelling reasons. First, our self-cleaning nano-coating option dramatically reduces maintenance costs by preventing dirt accumulation and making rainwater effectively wash away surface contaminants. Second, the scratch-resistant surface treatment maintains perfect appearance through transportation, fabrication, and installation.

Most importantly, our environmentally responsible production process meets the strictest global regulations including EU REACH and RoHS, with VOC emissions reduced to near-zero levels. The coils are equally suitable for extreme climates - from desert heat to coastal salt spray environments - making them ideal for international projects where consistent quality is non-negotiable.

The production journey of our PPGI Coils begins with meticulous surface preparation. Our eight-stage chemical pretreatment removes all impurities from the galvanized substrate before applying a uniform conversion coating. The precision coating process utilizes computer-controlled reverse roller application to achieve perfect film thickness (20-27μm) with variations under ±1μm.

In our 200-meter-long curing ovens, multi-zone temperature control (±2°C accuracy) ensures complete cross-linking of the paint system. The final inspection includes automated spectrographic analysis of color consistency and electronic coating thickness measurement at multiple points across the coil width. This rigorous quality control guarantees that every square meter meets our exacting standards before shipment.

The versatility of YingYee's PPGI Coils continues to expand across global markets:

Architectural Cladding: Creating stunning facades for commercial towers and cultural centers that maintain their brilliance for decades

Industrial Roofing: Providing durable, weather-tight protection for factories and warehouses

Home Appliances: Forming scratch-resistant surfaces for premium refrigerators and oven exteriors

Transportation Infrastructure: Serving as durable roofing material for airports and high-speed rail stations