(eps sandwich panel making machine)

The construction materials sector shows 11.2% annual growth in prefabricated solutions, driven by EPS sandwich panel machines capable of producing 45-75 panels/hour. These systems combine EPS core insulation (R-values up to 5.28 per inch) with steel/aluminum facings, achieving fire ratings up to Class A (ASTM E84).

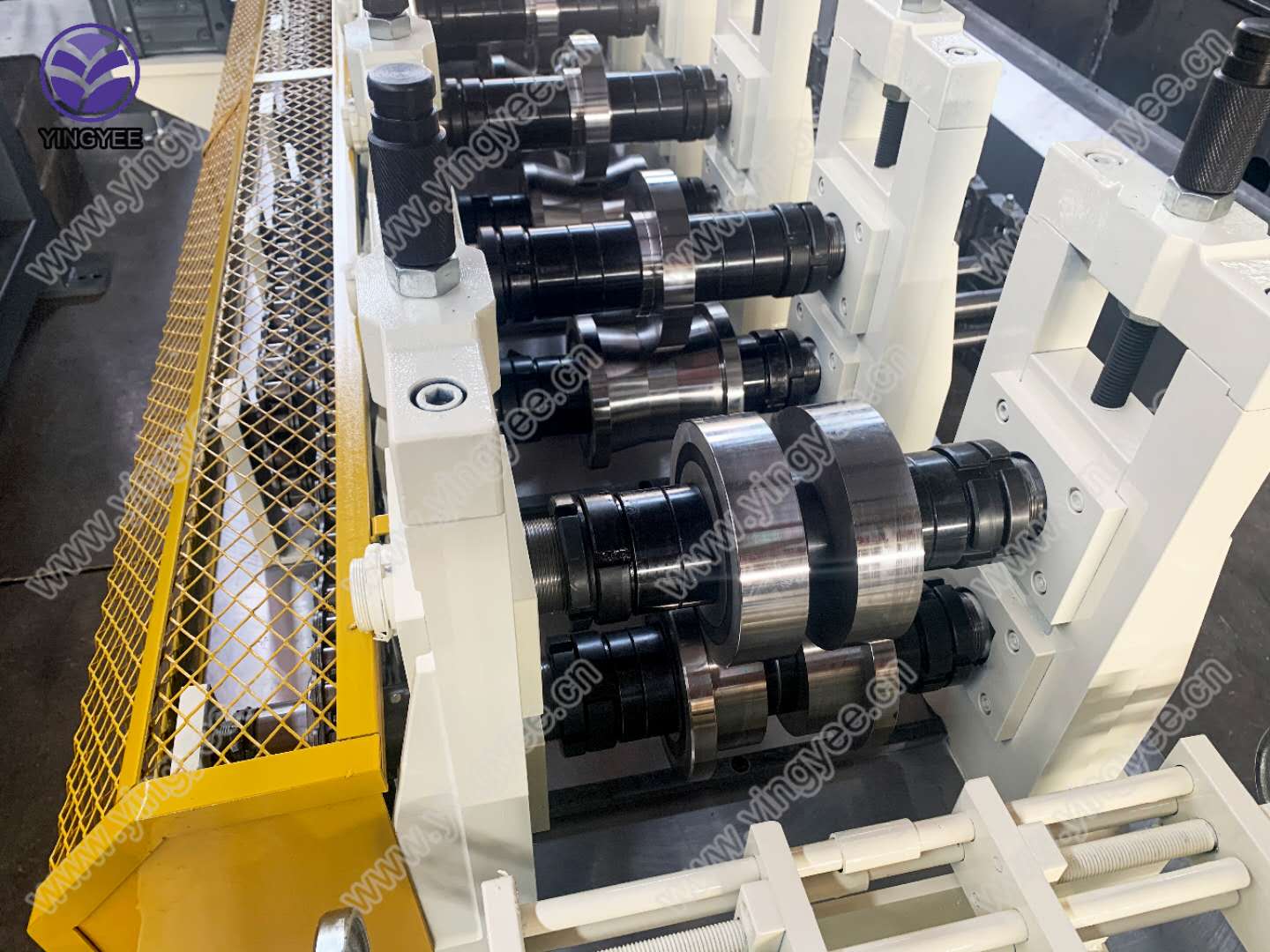

Third-generation machines now integrate IoT-enabled quality control sensors (±0.15mm tolerance) and energy recovery systems reducing power consumption by 32%. The table below compares key operational metrics:

| Feature | Standard Model | Premium Model | Industrial Model |

|---|---|---|---|

| Output Capacity | 18-22 m²/min | 25-30 m²/min | 35-40 m²/min |

| Energy Consumption | 65 kWh | 48 kWh | 42 kWh |

| Panel Thickness Range | 30-150mm | 20-200mm | 15-300mm |

Market leaders demonstrate distinct capabilities across production scales:

| Vendor | Cycle Time | Customization | Price Range |

|---|---|---|---|

| AlphaCore Systems | 22 sec | 85% components | $185K-$420K |

| Polaris Manufacturing | 19 sec | Full BIM integration | $310K-$575K |

Modular designs enable rapid switching between:

ROI analysis reveals:

A Middle Eastern contractor achieved 1.2M m² annual production using dual-line EPS sandwich panel machines, reducing labor costs by 40% while maintaining 99.3% dimensional accuracy.

Next-generation machines incorporate AI-driven predictive maintenance (87% downtime reduction) and closed-loop material systems achieving 94% recycling rates. These advancements position EPS panel machinery as essential for meeting 2025 energy efficiency mandates across 38 countries.

(eps sandwich panel making machine)

A: An EPS sandwich panel making machine automates the production of insulated panels by bonding EPS foam cores with metal or other facing materials. It ensures consistent quality and high output for construction and industrial applications.

A: Unlike standard panel machines, EPS sandwich panel machines specialize in integrating EPS foam insulation between two outer layers. They use precise temperature control and pressure systems to optimize thermal and structural properties.

A: The price depends on automation level, production capacity, material compatibility, and brand. Advanced features like CNC controls or dual-side coating systems significantly increase costs compared to basic models.

A: Yes, options include continuous production lines for large-scale output and batch-type machines for customized panels. Some machines focus on specific materials like steel, aluminum, or fire-resistant coatings.

A: Prices range from $50,000 for semi-automatic models to over $500,000 for fully automated systems. Custom configurations or high-speed production lines may exceed this range.