The Steel Cable Tray Making Roll Forming Machine An Essential Tool for Modern Infrastructure

In the construction and electrical industries, the efficient management of cables is crucial for the safety and functionality of electrical systems. One effective solution for organizing and protecting cables is the use of cable trays, particularly those made from steel due to their durability and strength. The process of manufacturing these steel cable trays relies heavily on advanced technology, specifically the roll forming machine.

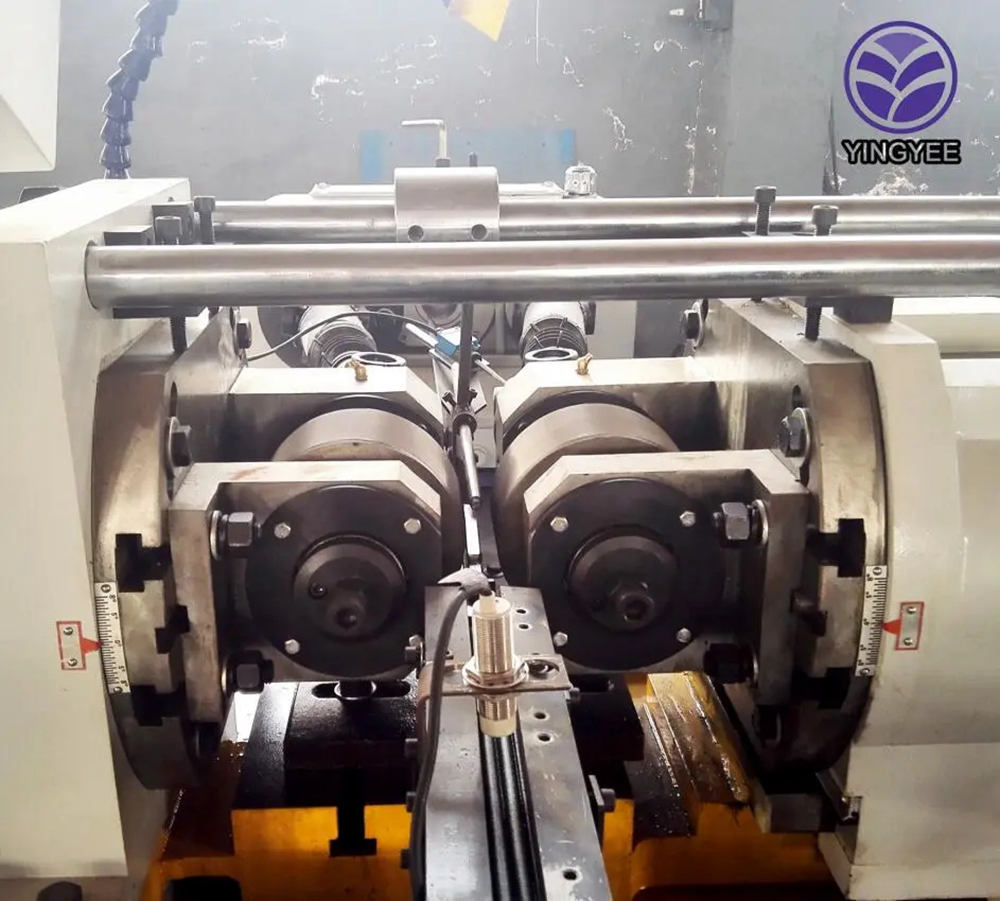

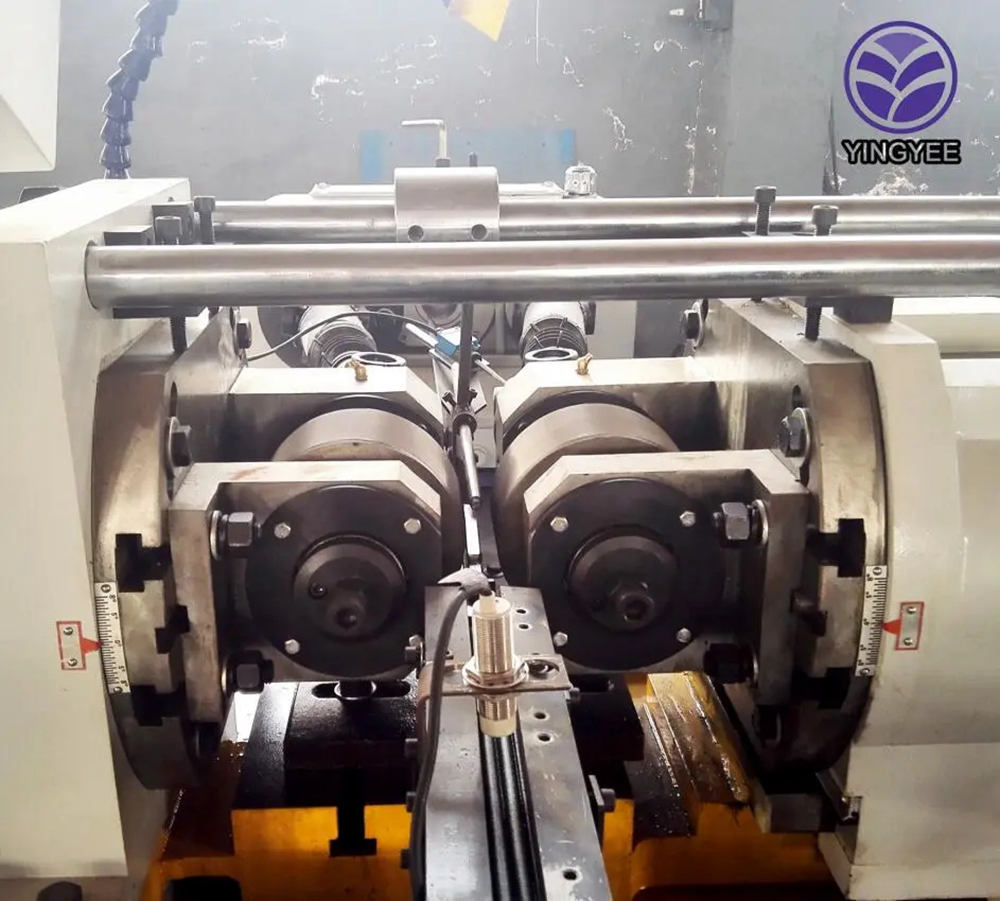

A steel cable tray making roll forming machine is designed to produce cable trays that serve as a support system for electrical wiring and cables in commercial and industrial settings. The roll forming process involves the continuous bending of strips of steel into desired shapes using a series of rollers. This manufacturing technique is not only efficient but also ensures precision and consistency in the dimensions of the trays produced.

One of the standout features of roll forming machines is their ability to create complex profiles with minimal waste. The process allows manufacturers to use high-quality steel strips, which are fed through multiple stations of rollers that gradually shape the metal into the final product. This method not only enhances productivity but also reduces production costs by minimizing scrap material.

steel cable tray making roll forming machine

Moreover, steel cable trays made with roll forming machines are known for their robustness. Steel is inherently strong and resistant to corrosion, making it ideal for environments that require durability. The trays can withstand heavy loads and harsh conditions, making them suitable for various applications, including data centers, manufacturing plants, and commercial buildings. Additionally, they can be designed with features like perforations and side rails to improve airflow and provide extra support, further appealing to the unique needs of each customer.

Another important aspect of the production process is customization. Many roll forming machines can be adjusted to produce cable trays of various sizes and configurations, catering to specific project requirements. This flexibility is essential in a market where the demand for tailored solutions continues to rise. Manufacturers can produce a wide range of products, including standard trays, ladder trays, and wire mesh trays, each designed to meet safety standards while optimizing space and functionality.

The automation of the roll forming process brings another level of efficiency to steel cable tray production. Modern machines are often equipped with advanced control systems that streamline operations, reduce human error, and enhance overall safety in the manufacturing environment. With real-time monitoring capabilities, manufacturers can ensure that the quality of each batch meets strict industry standards.

In conclusion, the steel cable tray making roll forming machine represents a vital resource in the construction and electrical industries. Its ability to produce high-quality, durable cable trays efficiently makes it indispensable for supporting modern infrastructure. As technology continues to advance, the methods and machines used in cable tray production will likely evolve, further enhancing their efficiency and quality, ultimately contributing to safer and more organized electrical systems. As businesses continue to prioritize durability and cost-effectiveness, investing in advanced roll forming machines will be key to meeting these demands in an ever-changing market.