Understanding W Beam Guardrail Cold Bending Machines

In the realm of highway safety, W beam guardrails play a pivotal role in protecting vehicles from leaving the roadway and reducing the severity of accidents. These guardrails are engineered to absorb the impact from vehicles and redirect them back onto the road. The manufacturing of these crucial safety components involves specialized machinery, most notably the cold bending machine designed specifically for W beam guardrails. This article will delve into the significance of these machines, their operation, and their impact on road safety.

What is a W Beam Guardrail?

W beam guardrails are a type of roadside protection system constructed from high-strength steel. Their W-shaped profile provides a dynamic and flexible barrier that enhances vehicle containment and minimizes damage. The design is named after its cross-sectional shape, which resembles the letter W. This type of guardrail is favored for its effectiveness and is widely used in highways, bridges, and various other road applications.

The Role of Cold Bending Machines

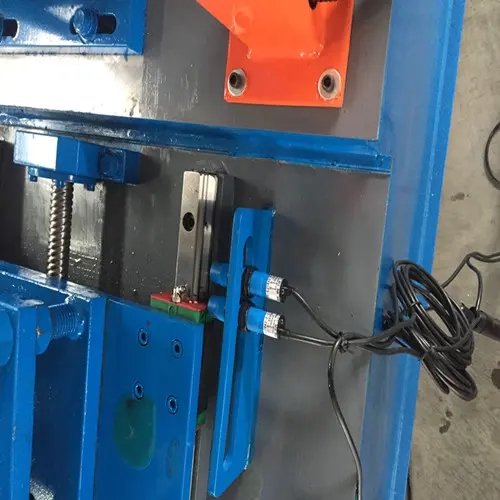

Cold bending machines are at the heart of the manufacturing process for W beam guardrails. These machines are critical for shaping the steel into the desired W profile without the application of heat, thus preserving the integrity and strength of the material. The process of cold bending allows for greater precision and control, resulting in high-quality guardrails that meet rigorous safety standards.

The effectiveness of these machines lies in their ability to manipulate steel sheets or strips into intricate shapes with minimal waste. By using a series of rollers and bending dies, the cold bending machine applies the necessary force to create the distinct W shape. This process is crucial, as the dimensions and angles of the guardrail significantly influence its performance in real-world collision scenarios.

Key Features of W Beam Guardrail Cold Bending Machines

1. Precision Engineering Cold bending machines are designed to deliver accurate dimensions and seamless curves. This precision is essential for ensuring that guardrails fit perfectly during installation and function optimally in real-world situations.

2. Efficiency Advanced models of these machines utilize automated processes, which enhance production speed and reduce labor costs. This efficiency is crucial for meeting the increasing demand for guardrails in road construction projects.

3. Versatility Many cold bending machines are capable of producing a variety of profiles and shapes beyond just the W beam, allowing manufacturers to diversify their product offerings without needing multiple machines.

4. Durability and Maintenance Modern cold bending machines are built to withstand the rigors of continuous operation. With proper maintenance, these machines can serve production facilities for years, ensuring a steady output of high-quality guardrails.

Impact on Road Safety

The production of W beam guardrails via cold bending machines has a significant impact on road safety. By ensuring that guardrails are manufactured to exact specifications, the likelihood of successful impact absorption is increased. Properly designed and installed guardrails can significantly reduce the risk of serious injury or fatalities during accidents.

Moreover, with advances in technology and materials, manufacturers are able to produce guardrails that not only meet but exceed safety standards. Innovations such as enhanced corrosion resistance and improved stiffness contribute to longer-lasting products that maintain their protective qualities over time.

Conclusion

The W beam guardrail cold bending machine is an indispensable tool in the production of one of the most critical components of highway safety. By combining precision, efficiency, and durability, these machines enable manufacturers to produce guardrails that enhance road safety and protect lives. As the demand for safer roads continues to grow, so too will the innovations in the machinery used to create protective barriers. As we look toward the future, investing in advanced manufacturing technologies will play a key role in improving the safety infrastructure of our roadways, ensuring a safer journey for all road users.