The Shelf Rack Upright Roll Forming Machine A Comprehensive Overview

In the modern manufacturing landscape, efficiency and precision are paramount. One of the key innovations that has emerged to address these demands is the shelf rack upright roll forming machine. This advanced equipment is essential for producing high-quality shelf rack uprights, which are critical components in warehouses, retail environments, and manufacturing facilities. This article will explore the significance, working principles, benefits, and applications of shelf rack upright roll forming machines.

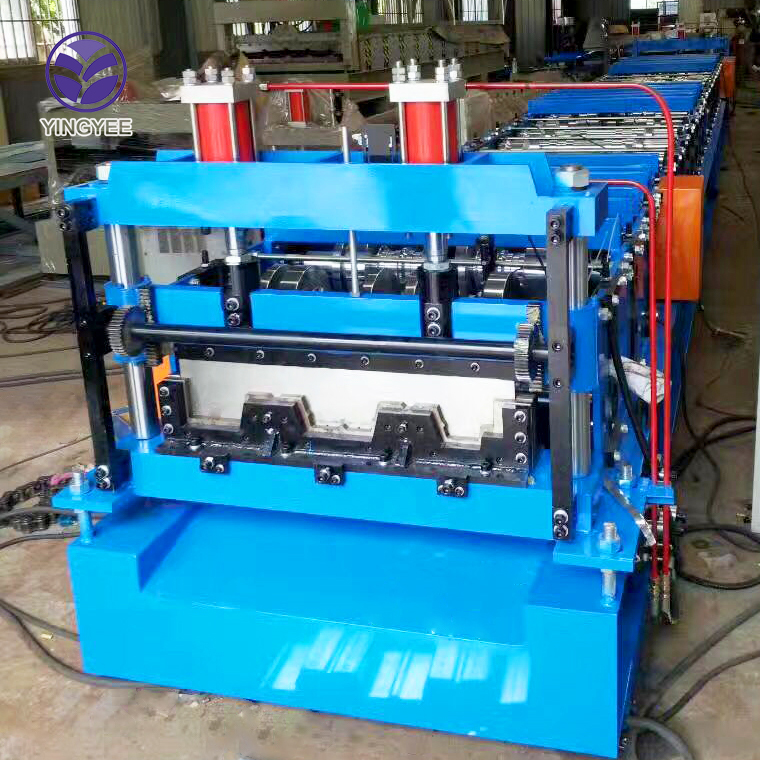

Understanding Shelf Rack Upright Roll Forming Machines

Roll forming is a continuous bending process in which a long strip of metal is slowly and gradually shaped into the desired profile through a series of rollers. A shelf rack upright roll forming machine is specifically designed to create vertical supports for shelving units, providing essential strength and stability. These uprights are typically made from steel or other durable materials, ensuring they can withstand heavy loads.

Working Principles

The operation of a shelf rack upright roll forming machine begins with feeding flat metal sheets into the machine. As these sheets pass through the series of rollers, they are gradually shaped into the upright profile required for shelf racks. The machine is equipped with various guide systems to ensure that the metal follows the intended path accurately. Once the desired shape is achieved, the formed profiles can be cut to the required lengths, often featuring holes for adjustable shelves and enhanced functionality.

One of the key features of these machines is their ability to produce multiple profiles with precision. Advanced CNC technology allows for easy adjustments to the machine settings, enabling manufacturers to switch between different designs without significant downtime.

Benefits of Using Shelf Rack Upright Roll Forming Machines

The advantages of utilizing these machines are manifold

1. High Efficiency Roll forming machines can operate at high speeds, significantly increasing production rates compared to traditional manufacturing methods. This efficiency is crucial for meeting market demands and reducing lead times.

2. Cost-Effectiveness By automating the production process, businesses can reduce labor costs while maintaining high production quality. The raw materials used in roll forming also tend to result in less waste compared to other manufacturing methods, further cutting costs.

3. Precision Engineering The roll forming process allows for tight tolerances, ensuring that each upright has consistent dimensions. This precision is vital for the structural integrity of shelving systems.

4. Customization Manufacturers can easily modify the machine settings to accommodate various designs and sizes, thus offering customized solutions to meet specific client needs. This flexibility is invaluable in a diverse marketplace.

5. Durability Products made from roll-formed metal are robust and have excellent structural strength, making them ideal for heavy-duty applications, which is crucial in warehouse and storage environments.

Applications

Shelf rack upright roll forming machines are widely used in various industries, including

- Warehousing Creating racking systems that maximize storage capacity and improve inventory management. - Retail Producing display racks that highlight products effectively and enhance customer experience. - Manufacturing Supplying components for assembly lines and production facilities, where organization and accessibility are vital. - Logistics Designing specialized racking systems that facilitate easier handling and transportation of goods.

Conclusion

The shelf rack upright roll forming machine is a game-changer in the manufacturing sector, offering an efficient, cost-effective, and precise solution for producing essential components of shelving systems. As industries continue to evolve and demand higher standards of efficiency and durability, these machines will play an increasingly crucial role in shaping the future of storage and organization solutions. By investing in this technology, manufacturers can ensure they remain competitive in a fast-paced marketplace, providing high-quality products that meet the needs of their customers.