Long Span Roll Forming Machine Revolutionizing the Metal Fabrication Industry

Introduction

In the realm of metal fabrication, efficiency and precision are paramount. Among the innovative technologies that have emerged, the long span roll forming machine stands out as a key development. Tailored to produce long lengths of metal profiles, this machine has become indispensable for industries ranging from construction to automotive.

What is a Long Span Roll Forming Machine?

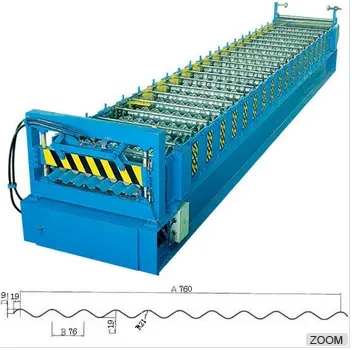

A long span roll forming machine is a specialized piece of equipment designed to shape metal sheets into predetermined profiles through a series of rollers. Unlike traditional roll forming machines that typically produce shorter lengths, long span machines can create extended sections, addressing the growing demand for larger steel and metal components. Common applications include roofing sheets, wall panels, and structural components used in buildings and other constructions.

Key Features and Benefits

1. Enhanced Efficiency One of the primary benefits of a long span roll forming machine is its ability to produce long metal profiles without the need for welding or joining shorter sections. This not only streamlines the manufacturing process but also reduces labor costs and production time.

2. Precision Engineering Long span roll forming machines are designed to deliver consistent accuracy. The advanced technology behind these machines ensures that the finished profiles are uniform in shape and size, meeting stringent quality standards. This is critical for applications where structural integrity is vital.

3. Versatile Production These machines can be customized to produce a wide range of profiles to cater to various industrial needs. Whether it is specific rib patterns for roofing or intricate designs for decorative elements, the flexibility of long span roll forming machines allows manufacturers to meet diverse customer requirements.

4. Reduced Material Waste The continuous nature of roll forming minimizes scrap material generated during production. This not only lowers material costs but also aligns with sustainability goals as manufacturers seek to reduce their environmental impact.

5. Cost-Effectiveness Although the initial investment in a long span roll forming machine may be higher than traditional options, the long-term savings in labor, material waste, and production efficiency often justify the cost. Additionally, the ability to produce large quantities of high-quality profiles can enhance profitability.

Applications in Various Industries

The applications of long span roll forming machines are extensive and varied. In the construction industry, they are primarily used for producing metal roofing and wall panels, which are vital components in modern building designs. These machines can create profiles that not only offer structural support but also contribute to the aesthetics of a building.

In the automotive sector, long span roll forming machines are utilized to manufacture various structural parts, contributing to vehicle strength while maintaining light weight. This aligns with the ongoing trend of producing fuel-efficient vehicles, as manufacturers strive to reduce overall vehicle weight without compromising safety.

Another significant application lies in the manufacturing of metal furniture, where designers require long, sleek profiles for tables, desks, and shelving. The ability to produce these components in custom lengths enhances the design possibilities for furniture manufacturers.

Conclusion

The long span roll forming machine is quickly becoming an essential tool for industries requiring efficiency and high-quality metal profiles. Its advantages in production efficiency, precision, material waste reduction, and versatility make it a smart investment for manufacturers seeking to stay competitive in today's fast-paced market. As technology continues to advance, we can expect further innovations in roll forming processes, potentially leading to even more streamlined operations and expanded applications.

As businesses adapt to evolving customer demands and sustainability challenges, the long span roll forming machine will undoubtedly play a critical role in shaping the future of metal fabrication, ensuring that manufacturers can meet their operations' needs while also prioritizing quality and efficiency. Whether in construction, automotive, or furniture production, the impact of this technology will continue to resonate across various sectors, transforming the landscape of metalworking for years to come.