Understanding C Channel Steel Roll Forming Machines

C channel steel has become an integral part of modern construction due to its versatile applications and structural strength. The demand for C channel steel has led to the adoption of advanced manufacturing technologies, among which C channel steel roll forming machines stand out. This article will explore the functionality, advantages, and applications of these machines, providing insights into their importance in the steel processing industry.

What is a C Channel Steel Roll Forming Machine?

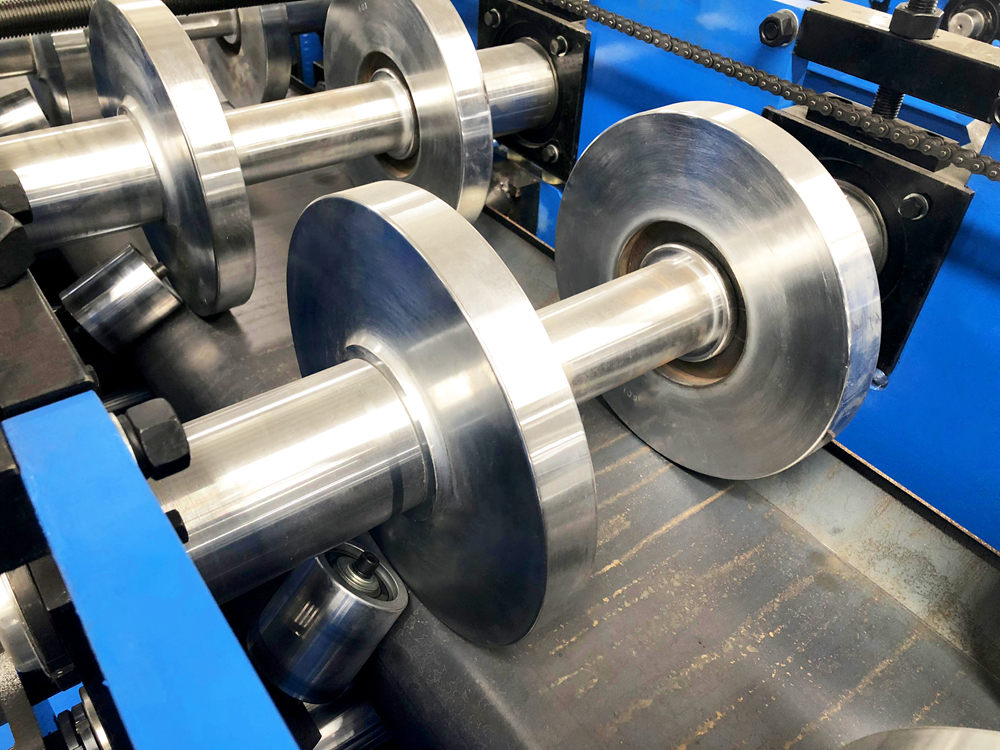

A C channel steel roll forming machine is a specialized equipment designed to fabricate C-shaped steel channels from steel coils. The process involves feeding flat steel sheets into the machine, which then utilizes a series of rollers to gradually form the metal into the desired C shape. This technique ensures high precision and uniformity in channel production, making it a popular choice among manufacturers.

The Working Principle

The roll forming process begins with uncoiling the flat steel sheet and feeding it through a series of forming rollers. Each roller is strategically placed to shape the steel gradually. The steel passes through multiple stages, where each roll further bends it to form a C channel. After the desired profile is achieved, the formed channels are cut to the required length. The entire process is continuous and highly efficient, allowing for high production speeds and minimal waste.

Advantages of C Channel Steel Roll Forming Machines

1. Efficiency and Speed One of the key advantages of using roll forming machines is their ability to produce C channels at a high speed. The continuous nature of the process allows for mass production, which is particularly beneficial in meeting large-scale project demands.

2. Precision and Consistency Roll forming machines offer a high level of accuracy, ensuring that each C channel produced meets strict industry standards. This precision helps reduce the need for secondary operations, saving time and costs.

3. Material Savings The design of roll forming machines minimizes waste by utilizing the full width of the steel coil. This efficient use of materials not only reduces costs but also makes the manufacturing process more environmentally friendly.

4. Versatility These machines can produce channels of various sizes and thicknesses, making them suitable for a wide range of applications. Additionally, they can be modified or equipped with different tooling to produce different profiles, enhancing their versatility.

5. Durability and Low Maintenance C channel steel roll forming machines are built to last, with robust construction that can withstand the rigors of continuous operation. Moreover, they require relatively low maintenance, ensuring minimal downtime in production.

Applications of C Channel Steel

C channel steel is used in a variety of construction and engineering applications, including

- Structural Support C channels are commonly used as beams, columns, and supports in buildings, bridges, and other structures due to their strength and ability to bear heavy loads. - Framework and Racking Systems In warehouses and industrial settings, C channels serve as framework components for shelving and racking systems, providing structural stability. - Manufacturing Many manufacturing processes utilize C channel steel for fabrication equipment, machinery supports, and conveyor systems.

- Automotive and Aerospace C channels can also be found in automotive and aerospace applications, where they provide structural integrity and support within vehicles and aircraft.

Conclusion

C channel steel roll forming machines play a crucial role in the manufacturing of C channel steel, offering numerous advantages in efficiency, precision, and versatility. As the demand for C channel steel continues to rise in various industries, the importance of these machines in modern manufacturing cannot be overstated. By investing in advanced roll forming technology, manufacturers can enhance their production capabilities and meet the evolving needs of the construction and engineering sectors. The future of C channel steel production looks promising, driven by ongoing innovations in roll forming technology.