Alaye ipilẹ

Nọmba awoṣe:YINGYEE003

Atilẹyin ọja:12 osu

Akoko Ifijiṣẹ:30 Ọjọ

Lẹhin Iṣẹ:Enginners Wa Lati Service Machinery Okeokun

Foliteji:380V/3Alakoso/50Hz Tabi Ni Ibere Rẹ

Ipo gige:Epo eefun

Ohun elo ti Ige abẹfẹlẹ:K12

Eto Iṣakoso:PLC

Afikun Alaye

Iṣakojọpọ:plastic film

Isejade:200 tosaaju / odun

Brand:YY

Gbigbe:Okun, Ilẹ, Afẹfẹ

Ibi ti Oti:Hebei

Agbara Ipese:200 tosaaju / odun

Iwe-ẹri:CE/ISO9001

Koodu HS:84552210

Ibudo:Tianjin, Shanghai, Qingdao

ọja Apejuwe

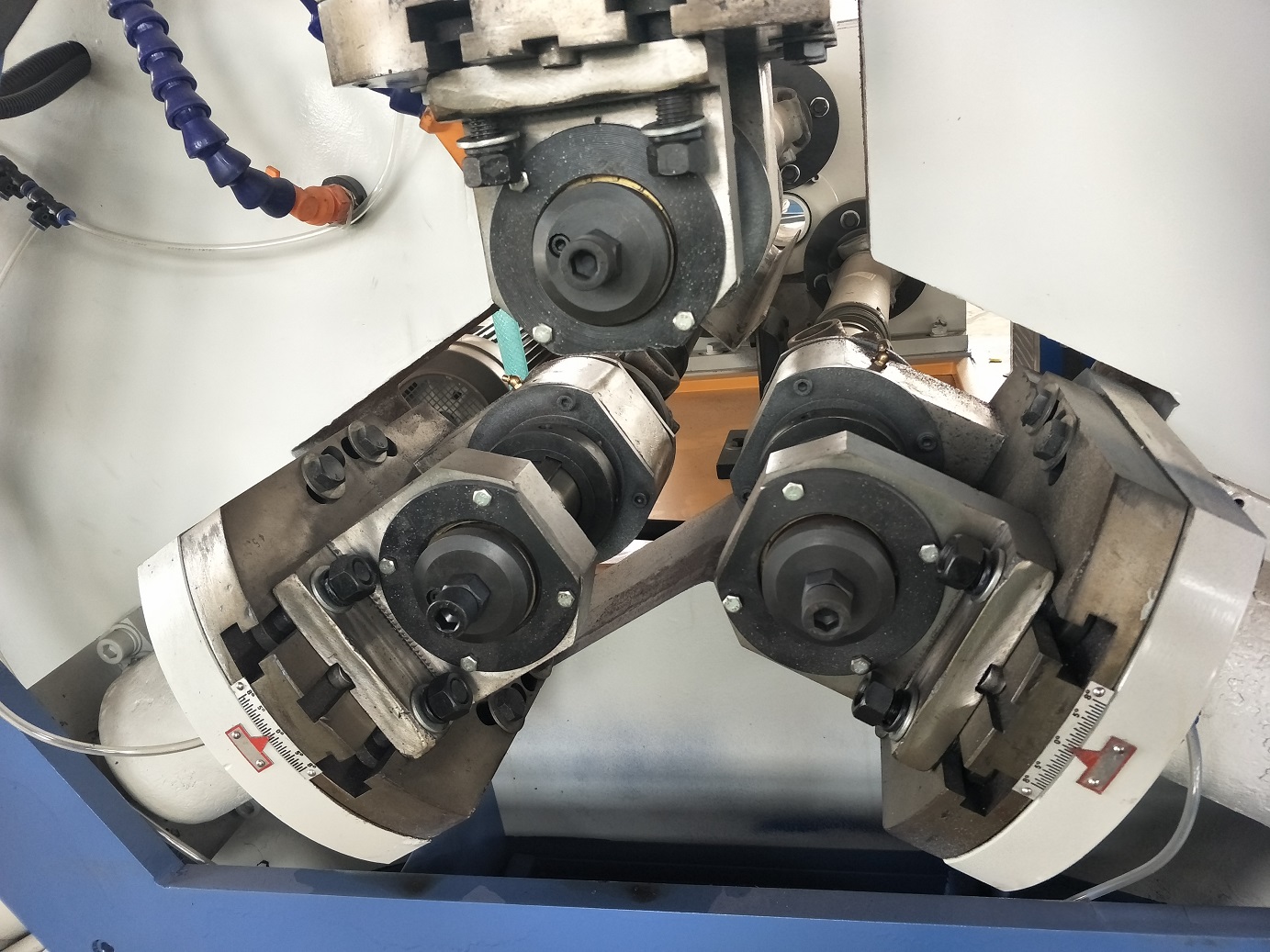

maximum pressure 250KN steel pipes Opo sẹsẹ Machine with three shaft

Due to teeth of an internal roller brush wheel and an external roller brush wheel under the preset pressure of a spring, a steel pipe wall is bent and deformed and simultaneously is driven to rotate by the rotation of the internal roller brush wheel and the external roller brush wheel, the tube wall can generate heat due to the friction of the rotation line speed difference of the internal roller brush wheel and the external roller brush wheel, so that the strength of the material is lowered; the material can generate rebound fatigue due to continuous rolling brush of the internal roller brush wheel and the external roller brush wheel, so that along with gradual decreasing of the rebound deform performance of the tube wall material, the teeth of the roller brush wheel are gradually pressed into the tube wall under the preset pressure, the tube wall is molded and deformed according to the teeth of the internal roller brush wheel and the external roller brush wheel, so as to form cylinder tube threads or internal and external threads of a conic tube. The thread rolling machine has the characteristic that the molded thread is low in stress, so that the middle wall of the tube can be molded with threads, and the problem of stress corrosion of stainless steel in rolling threads can be solved, furthermore, the middle wall pipeline connected with the threads molded by the machine can be used for replacing the high pressure endured by the thickened tube wall of the molded threads through cutting, the defect that the source nipple loosens and leaks due to stress concentration formed by grooves of cutting threads can be overcome, so that the source nipple can be as rigid as the tube body, and ideal stainless steel thread connection pipelines are provided for tubes of high pressure and middle pressure, particularly the fire control high pressure water mist fire extinguishing system (with the pipeline work pressure of 16MPa).

Awọn paramita imọ-ẹrọ:

| Titẹ ti Roller max. | 630KN | Iyara Rotari ti Ifilelẹ Ifilelẹ | 8,14,21,33(r/min) |

| Dia ṣiṣẹ | 120mm | Iyara kikọ sii ti ọpa gbigbe | 5mm/s |

| OD of Roller | 260mm | Opo gigun | (ko si opin) |

| BD ti Roller | 100mm | Yiyi Agbara | 15kw |

| Roller Width max | 200mm | Eefun agbara | 7.5kw |

| Dip Angle of Main Shaft | ±10° | Iwọn | 3000kg |

| Center Ijinna ti Main ọpa | 210-380mm | Iwọn | 2100×2270×2330mm |

Awọn aworan ẹrọ:

Alaye ile-iṣẹ:

YINGYEE ẹrọ ATI Iṣẹ IṣẸ CO., LTD

YINGYEE jẹ olupese ti o ni amọja ni ọpọlọpọ awọn ẹrọ iṣelọpọ tutu ati awọn laini iṣelọpọ adaṣe. A ni ẹgbẹ iyanu pẹlu imọ-ẹrọ giga ati awọn tita to dara julọ, eyiti o funni ni awọn ọja alamọdaju ati iṣẹ ti o jọmọ. A san ifojusi si opoiye ati lẹhin iṣẹ, ni awọn esi nla ati ọlá fun awọn alabara. A ni kan nla egbe fun lẹhin iṣẹ. A ti firanṣẹ ọpọlọpọ alemo lẹhin ẹgbẹ iṣẹ si okeokun lati pari fifi sori ọja ati atunṣe. Awọn ọja wa ti ta si diẹ sii ju awọn orilẹ-ede 20 lọ tẹlẹ. Tun pẹlu US ati Germany. Ọja akọkọ:

FAQ:

Ikẹkọ ati fifi sori ẹrọ:

1. A nfun iṣẹ fifi sori agbegbe ni sisanwo, idiyele idiyele.

2. QT igbeyewo kaabo ati ki o ọjọgbọn.

3. Afowoyi ati lilo itọsọna jẹ iyan ti ko ba si abẹwo ati ko si fifi sori ẹrọ.

Ijẹrisi ati lẹhin iṣẹ:

1. Baramu imọ-ẹrọ imọ-ẹrọ, iwe-ẹri iṣelọpọ ISO

2. CE iwe eri

3. 12 osu atilẹyin ọja niwon awọn ifijiṣẹ. Ọkọ.

Anfani wa:

1. Akoko ifijiṣẹ kukuru

2. ibaraẹnisọrọ to munadoko

3. Interface adani.

Looking for ideal The Thread Rolling Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Pipes Thread Rolling Machine are quality guaranteed. We are China Origin Factory of Three Shaft Thread Rolling Machine. If you have any question, please feel free to contact us.

Ọja Isori: O tẹle sẹsẹ Machine