Steel Curving Unistrut Roll Forming Machine Revolutionizing Metal Construction

In the modern construction industry, efficiency, precision, and reliability are paramount. Among the various tools and machines that contribute to these goals, the steel curving Unistrut roll forming machine has emerged as a pivotal component in metal fabrication processes. This innovative machinery allows manufacturers to produce high-quality, accurately curved Unistrut channels, which are essential in countless applications, from framing and support systems to electrical and plumbing installations.

Understanding Unistrut Systems

Unistrut systems are structural framing systems composed of channels that serve as versatile supports for various applications. These channels are often utilized for mounting electrical conduits, HVAC systems, and piping. The flexibility and strength of Unistrut systems make them indispensable in commercial, industrial, and residential projects. However, to achieve the desired structural integrity and aesthetic appeal, precise curving capabilities are required.

The Role of Roll Forming Machines

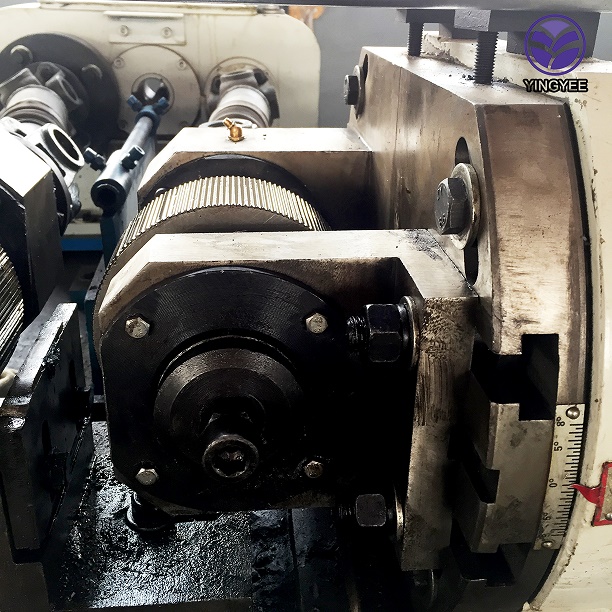

Roll forming is a continuous bending process in which a long strip of metal is fed through a series of rollers that gradually shape it into a desired profile. The steel curving Unistrut roll forming machine specializes in this technique, allowing for the production of curved Unistrut channels with specific radii and dimensions. The roll forming machine not only enhances production efficiency but also ensures consistency and accuracy in the final products.

Advantages of Steel Curving Unistrut Roll Forming Machines

1. Precision Engineering One of the primary benefits of using roll forming machines is the high level of precision they offer. The machine's ability to create accurately curved channels reduces material waste and minimizes errors, which is crucial in construction where even minor inaccuracies can lead to significant issues.

2. Versatility and Customization Steel curving Unistrut roll forming machines can be adapted to produce various profiles and dimensions. This versatility allows manufacturers to cater to the specific needs and preferences of clients, producing unique solutions for distinct projects.

3. Cost-Effectiveness Although the initial investment in a steel curving roll forming machine may be significant, the long-term cost benefits are substantial. The efficiency of the production process leads to reduced labor costs and lower material waste, making it an economically sound choice for manufacturers.

4. Increased Output Modern roll forming machines are designed for high-speed operation, which dramatically increases output. This is particularly advantageous for larger construction projects that require significant quantities of Unistrut channels.

5. Automation Capabilities Many of today’s steel curving Unistrut roll forming machines are equipped with advanced automation features. This not only streamlines the production process but also reduces the likelihood of human error, further enhancing product consistency.

Applications Across Industries

The impact of steel curving Unistrut roll forming machines extends beyond just construction. These machines are essential in various sectors, including automotive, aerospace, and telecommunications, where customized metal profiles are frequently required. The ability to produce curved Unistrut channels quickly allows companies to adapt to varying project demands, ensuring that they remain competitive in the ever-evolving marketplace.

Conclusion

In summary, the steel curving Unistrut roll forming machine represents a significant advancement in metal fabrication technology. Its ability to produce precise, customized, and cost-effective Unistrut channels makes it an essential tool in modern construction and beyond. As the demand for efficient and versatile structural solutions continues to grow, these machines will play a crucial role in shaping the future of various industries. By investing in steel curving Unistrut roll forming machines, manufacturers can enhance their operational capabilities and ensure they meet the dynamic needs of their customers.