(pu sandwich panel line)

The continuous PU sandwich panel line represents a paradigm shift in construction material production. Modern systems achieve 12-15 meters/minute output speeds while maintaining ±0.3mm dimensional accuracy, with 98.7% material utilization rates. This technology enables:

Contemporary polyurethane sandwich panel lines incorporate closed-loop thermal regulation achieving ±1°C stability. The table below compares key operational parameters:

| Parameter | Standard Line | Premium Line | Industrial Line |

|---|---|---|---|

| Daily Output | 4,800 m² | 6,500 m² | 8,200 m² |

| Energy Consumption | 38 kW/h | 29 kW/h | 22 kW/h |

| Panel Density | 40-45 kg/m³ | 38-42 kg/m³ | 35-40 kg/m³ |

| Fire Resistance | Class B1 | Class A2 | Class A1 |

Market leaders demonstrate distinct operational profiles:

Modern continuous sandwich panel lines offer modular configurations:

Energy consumption analysis reveals:

| Component | Standard Line | Optimized Line |

|---|---|---|

| Heating System | 4.2 kW/m² | 2.8 kW/m² |

| Cooling Cycle | 3.1 kW/m² | 1.9 kW/m² |

| Material Handling | 0.7 kW/m² | 0.4 kW/m² |

A Middle Eastern facility achieved:

Strategic implementation of continuous PU sandwich panel lines requires balancing capital expenditure with operational parameters. Advanced systems now achieve 92% automated operation, reducing human intervention to critical decision points while maintaining 0.25% defect rates across production cycles.

(pu sandwich panel line)

A: A PU sandwich panel line is designed to manufacture polyurethane-insulated panels for construction, cold storage, and industrial applications. It automates the process of layering metal sheets with PU foam core. This ensures high insulation efficiency and structural durability.

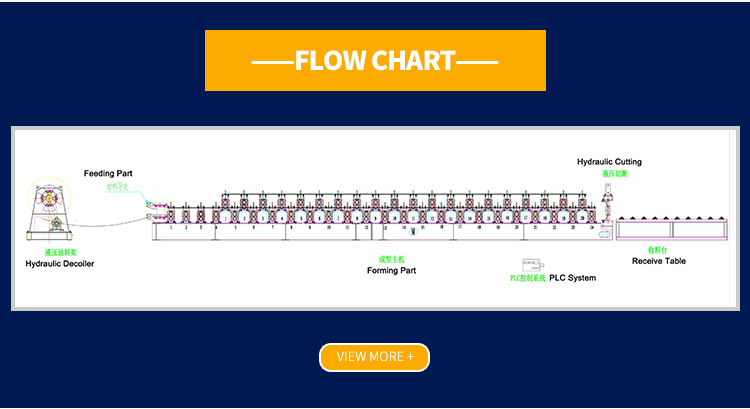

A: A continuous PU sandwich panel line feeds metal coils and PU foam raw materials into a synchronized system. The materials are heated, pressed, and cured to form seamless panels. This method ensures uniform thickness and faster production rates.

A: A polyurethane sandwich panel line offers excellent thermal insulation, fire resistance, and lightweight properties. It reduces energy costs in buildings and supports eco-friendly construction. Automated systems also minimize labor and material waste.

A: Regular maintenance includes checking hydraulic systems, cleaning conveyors, and calibrating foam dispensing units. Lubricating moving parts and inspecting electrical components ensures longevity. Scheduled downtime helps prevent unexpected breakdowns.

A: Production speed depends on panel thickness and complexity, but modern lines can produce 10-25 meters per minute. Advanced curing systems and automation optimize output. Custom configurations can further enhance efficiency.

A: Key factors include raw material quality, foam mixing precision, and temperature control during curing. Consistent pressure application and accurate cutting systems also matter. Regular quality checks ensure compliance with industry standards.

A: Yes, lines can be tailored for panel dimensions, core materials, and surface finishes. Options include adjustable speed controls, additional coating systems, and specialized cutting tools. Customization ensures alignment with project requirements.