Pipe thread rolling machines are the unsung heroes of the pipe and fittings manufacturing industry, revolutionizing how threaded connections are made. These machines are lauded for their precision, efficiency, and ability to enhance the durability of pipe threads, which are essential for ensuring leak-proof and pressure-tight connections in various industrial applications. Here, we delve into the profound capabilities and technical intricacies of pipe thread rolling machines, illuminating why they are indispensable in modern manufacturing.

Pipe thread rolling is a process that involves deforming a pipe's surface to form threads without removing material, unlike traditional cutting methods.

This process offers several advantages. First, the rolled threads boast increased fatigue resistance and strength due to the material's fibrous structure remaining unbroken. This characteristic is crucial for applications subjected to extreme pressures and temperatures, such as in the oil and gas industry or high-pressure hydraulic systems.

The expertise behind these machines lies primarily in their construction and operating principles. Advanced pipe thread rolling machines utilize high-quality rolling dies made from robust materials like high-speed steel or tungsten carbide, tailored to endure significant stress during operation. These dies not only ensure precision but also extend the machine’s service life, offering a cost-effective solution for manufacturers.

Operational efficiency is another cornerstone of these machines' superiority. By leveraging computer numerical control (CNC) technology, modern pipe thread rolling machines achieve impeccable accuracy and consistency, reducing waste and machine downtime. Operators can pre-program the machines for different pipe sizes and thread specifications, ensuring seamless production runs that align with industry standards such as NPT, BSPT, and ISO threads.

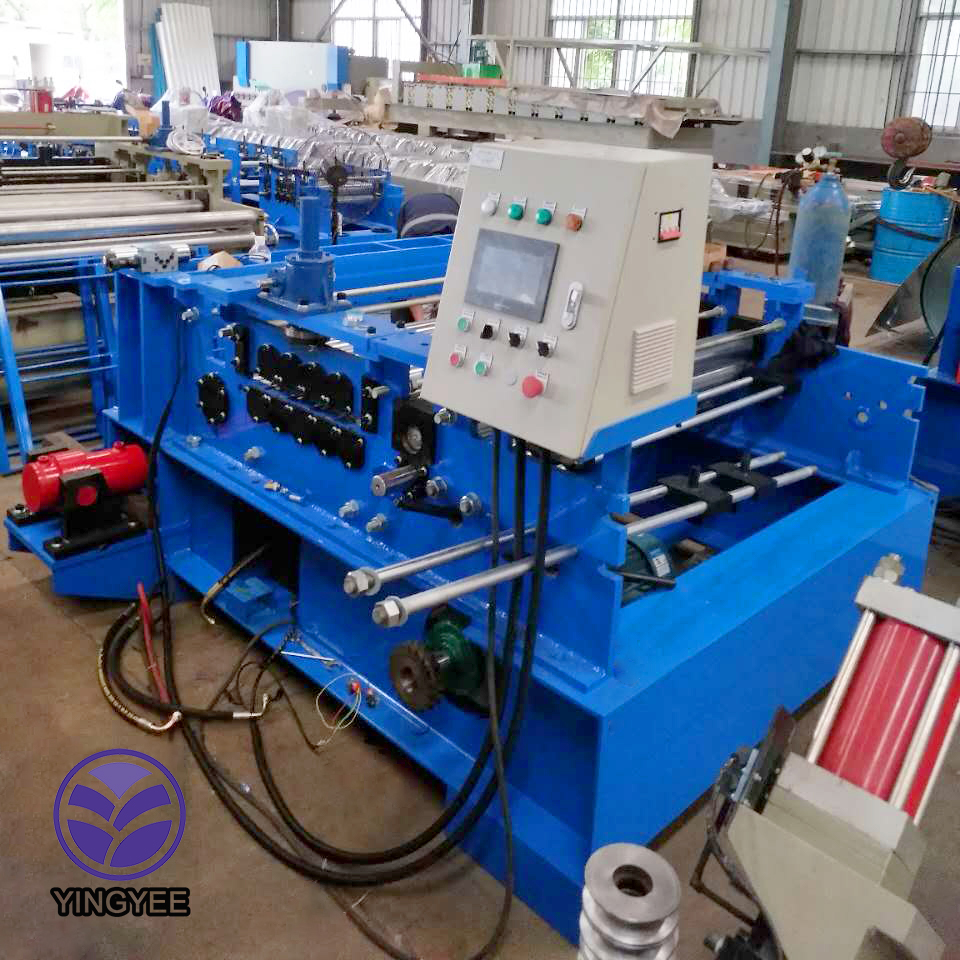

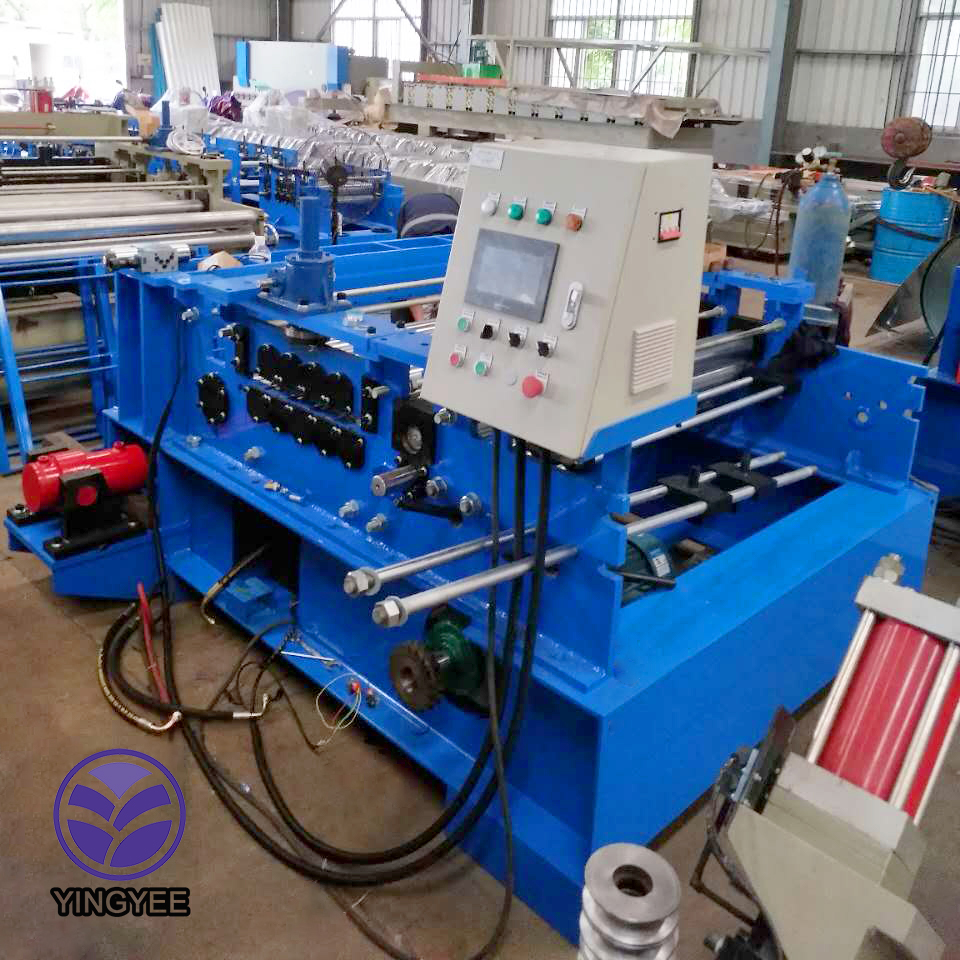

pipe thread rolling machine

Authoritativeness in the field is established through adherence to stringent manufacturing standards and certifications. Leading manufacturers provide machines that comply with ISO 9001 quality management systems, guaranteeing a high-level quality assurance mechanism. This compliance not only enhances customer trust but also fortifies the machines' credibility as reliable assets in production lines globally.

Real-world experience further attests to the efficacy of pipe thread rolling machines. Manufacturers using these machines report significant improvements in production speed, lower defect rates, and enhanced product durability, attributing these outcomes to the advanced capabilities of thread rolling. Testimonials from prominent players in sectors like plumbing, automotive, and marine industries underscore the transformative impact of these machines.

To bolster trustworthiness, manufacturers offer extensive after-sales support, including operator training, regular maintenance services, and rapid availability of spare parts. Building a solid relationship with clients ensures machines operate at peak performance, minimizing any disruptions that could lead to costly setbacks.

In sum, pipe thread rolling machines epitomize the pinnacle of engineering mastery in the threading industry. Their integration into manufacturing processes signposts a shift towards more sustainable and efficient production systems, vital for meeting the ever-evolving demands of industries worldwide. The union of expert craftsmanship, cutting-edge technology, and unwavering commitment to quality makes these machines a prudent investment for any forward-thinking manufacturer.