Navigating the intricate world of nut and bolt manufacturing demands precision and efficiency, which is where the nut and bolt thread rolling machine becomes indispensable. Its ability to shape threads on workpieces through a process of deformation, rather than cutting, marks it out as a vital piece of machinery for manufacturers aiming to optimize their production lines.

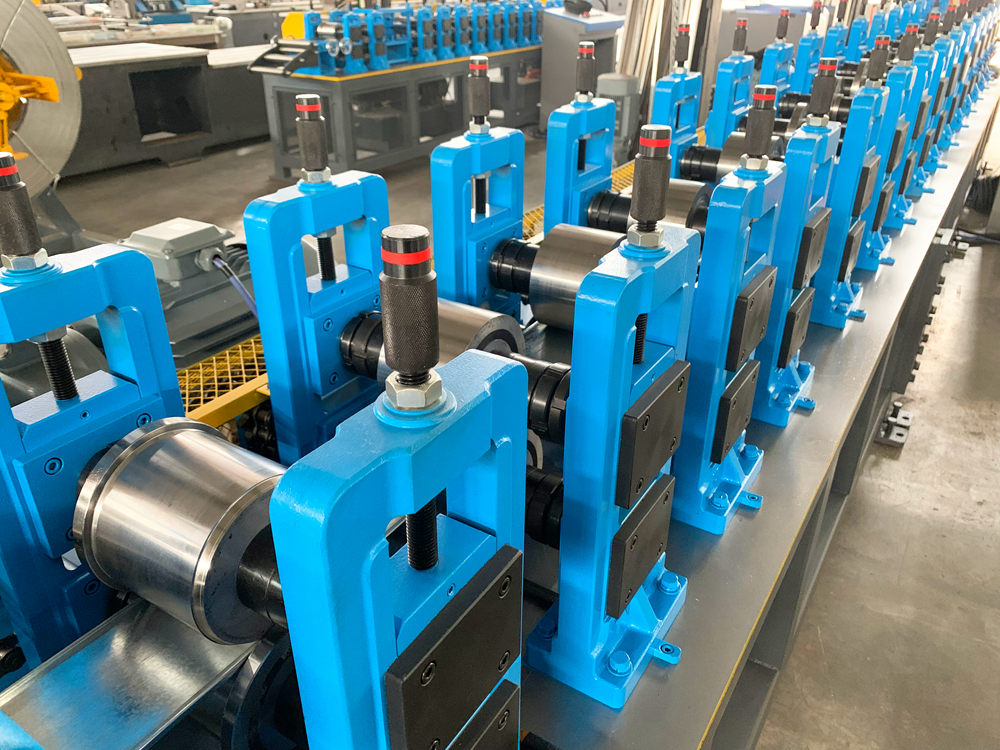

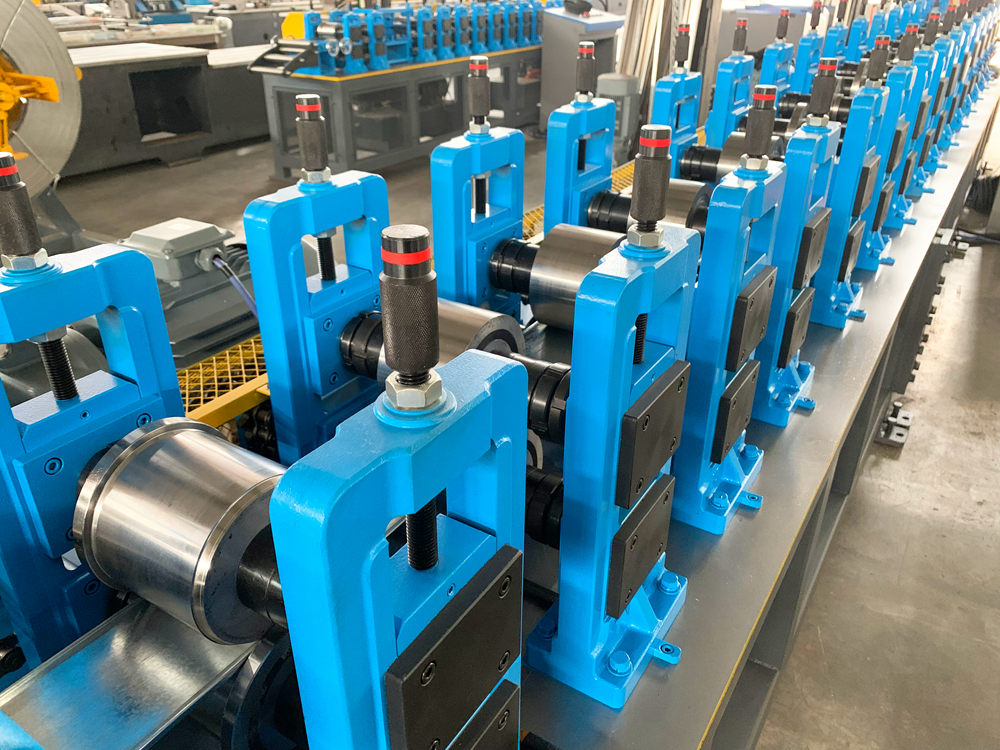

Thread rolling machines have become synonymous with premium quality and strength in fasteners, enhancing the durability and performance of the nuts and bolts produced. These machines utilize hardened steel dies to press threads onto a fastener blank. This process not only increases the material strength by aligning the grain structure of the metal but also ensures a higher degree of consistency and precision, essential for applications where reliability is paramount.

The efficiency of the thread rolling process is a key factor in its widespread adoption. Traditional thread cutting methods often generate significant material waste, whereas thread rolling optimally utilizes the material, yielding stronger threads without compromising on integrity. This results in cost savings on raw materials and aligns with environmentally sustainable practices, reducing the ecological footprint of manufacturing operations.

Manufacturers seeking to implement these machines should consider several factors to maximize production outcomes. Understanding the machine’s capabilities is crucial—such as its thread size range, cycle time, and the materials it can handle. Furthermore, investing in machines from reputable suppliers ensures quality assurance, backed by comprehensive after-sales support, which is vital in maintaining operational continuity.

nut and bolt thread rolling machine

The expertise involved in operating thread rolling machines cannot be overstated. Skilled operators are essential, able to interpret engineering drawings and adjust machine settings to cater to different specifications. This underscores the need for continual training and development within the workforce, fostering a culture of excellence and attention to detail.

Moreover, utilizing a thread rolling machine not only contributes to operational efficiency but also elevates a manufacturer’s reputation in the market. Clients recognize the superior strength and reliability of rolled threads, leading to increased demand and potential for business growth. Adding to this, maintaining comprehensive records and documentation during production builds trust with customers, as it demonstrates a commitment to transparency and quality control.

Ultimately, the nut and bolt thread rolling machine stands as a beacon of technical advancement in the fastener industry. Its adoption translates into robust, high-quality products that meet the rigorous demands of modern engineering applications. When combined with strategic expertise and authoritative knowledge, these machines empower businesses to achieve remarkable competitiveness and trustworthiness in an ever-evolving market.

To thrive in such a dynamic environment, manufacturers must not only embrace the technological advancements provided by thread rolling machines but also cultivate a deep-seated expertise and dedication to quality. In doing so, they assure their position as leaders in the fastener industry, recognized for both their innovative spirit and unwavering commitment to superiority.