Understanding ERW Tube Mill Factories An Overview

Electric Resistance Welded (ERW) tube mills play a crucial role in the production of high-quality steel tubes used across various industries, including construction, automotive, and oil and gas. The primary function of an ERW tube mill is to manufacture hollow sections of steel that can be used for a myriad of applications. This article delves into the intricate workings of ERW tube mill factories, the technology behind them, and their significance in today’s production landscape.

What is ERW Technology?

ERW technology is based on the principle of electric resistance welding, a process that involves heating the edges of a steel strip until they reach welding temperature. This is achieved through the application of electrical resistance, and once the edges are heated sufficiently, they are pressed together under a specific amount of pressure, allowing them to bond seamlessly. This method is highly efficient and produces a strong and durable weld, which is essential for the structural integrity of the tubes.

The Production Process

The production of ERW tubes involves several stages

1. Raw Material Preparation The process begins with high-quality steel coils which are unwound and fed into the tube mill. The thickness, width, and quality of the steel are critical to the performance of the final product.

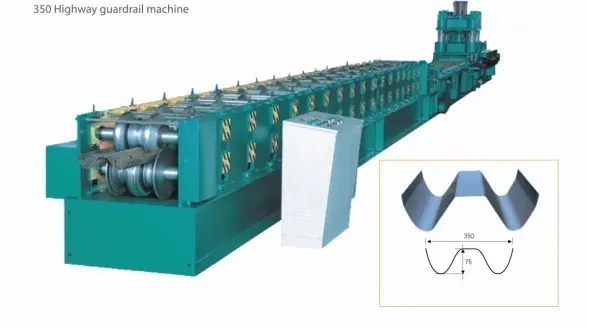

2. Forming the Tube The steel strip is then shaped into a tubular form using a series of rollers. The forming section of the mill molds the flat steel into a round or square tube, depending on the specifications.

3. Welding Once the tube is formed, it moves to the welding section where the edges are brought together and welded using the electric resistance method. This section is crucial as it ensures that the welded joint can withstand pressures and loads during usage.

4. Sizing and Straightening Post-welding, the formed tube is passed through a sizing mill to ensure it meets the precise dimensions required. Any curvature resulting from the welding process is corrected in this stage.

5. Inspection and Testing Quality control is paramount in an ERW tube mill. The tubes undergo a series of inspections and tests, including non-destructive testing methods like ultrasonic testing, to detect any flaws in the weld or material.

6. Finishing After passing all tests, the tubes are cut to length and can undergo various finishing processes such as galvanizing or coating to enhance resistance to corrosion and improve aesthetic value.

The Role of ERW Tube Mill Factories

ERW tube mill factories have emerged as vital components in the manufacturing landscape of the steel industry. They provide a cost-effective solution for producing tubes with tight tolerances and high strength. The efficiency of the ERW process, coupled with advancements in technology, has led to a decrease in production costs and an increase in the quality of the final products.

The versatility of ERW tubes makes them suitable for a wide range of applications. In the construction sector, they are commonly used for structural support, scaffolding, and fencing. In the automotive industry, ERW tubes serve as frames and structural components for vehicles. Moreover, in the oil and gas sector, they are used for pipelines, essential for transporting crude oil and natural gas over long distances.

Challenges Faced by ERW Tube Mill Factories

While there are numerous advantages to ERW technology, factories face challenges that can impact production efficiency. One significant issue is the fluctuation of raw material costs, which affects profitability. Additionally, strict regulatory standards in various regions necessitate ongoing compliance and quality control efforts, requiring factories to invest in advanced technology and skilled labor.

Conclusion

In conclusion, ERW tube mill factories are integral to the production of high-quality steel tubes that support various industrial applications. As technology continues to advance, these factories are poised to enhance their production capabilities while maintaining stringent quality standards. The future of ERW tube mills will likely be shaped by innovations that seek to improve efficiency, reduce costs, and comply with evolving regulations, ensuring that they continue to meet the demands of a growing global market. Regardless of the challenges, the role of ERW tube mills remains indispensable in the manufacturing landscape today.