Understanding Barrel Corrugated Roof Sheet Forming Machines

In the realm of modern construction and architecture, the demand for innovative roofing solutions is ever-increasing. Among these, barrel corrugated roof sheets have emerged as a popular choice due to their unique aesthetic and functional benefits. To manufacture these sheets efficiently, barrel corrugated roof sheet forming machines play a pivotal role. This article delves into the significance, operation, and advantages of these specialized machines.

What is a Barrel Corrugated Roof Sheet?

Barrel corrugated roof sheets are distinguished by their curved shape that resembles a barrel. This design provides a classic and aesthetically pleasing look, making them suitable for various applications, including residential homes, industrial buildings, and agricultural structures. The curvature helps in effectively shedding water and resisting wind uplift, enhancing the durability and longevity of the roof.

The Manufacturing Process

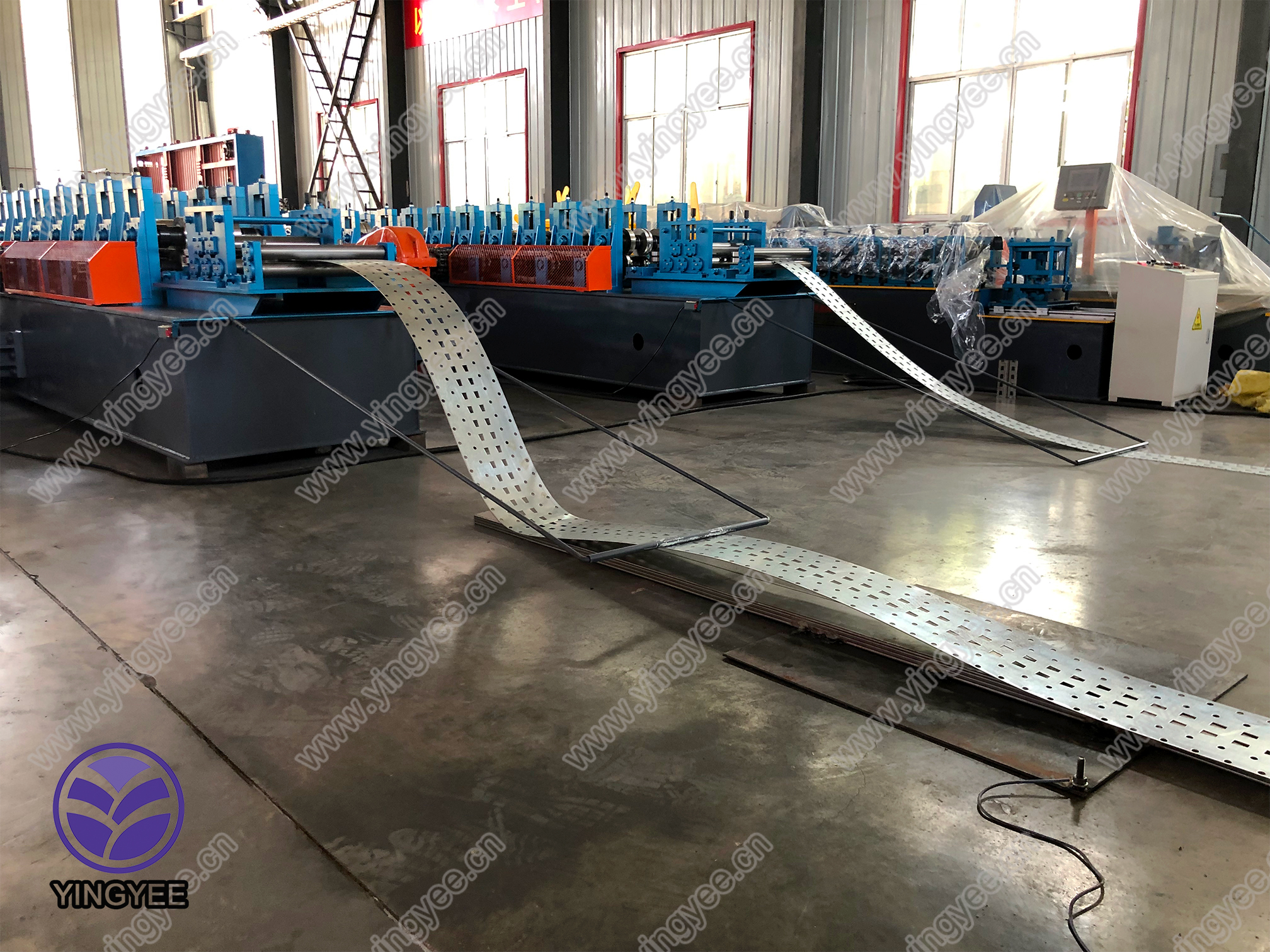

The production of barrel corrugated roof sheets involves several steps, all of which rely on the precision and efficiency provided by a forming machine. The core process includes

1. Material Preparation High-quality steel coils are utilized as the primary raw material. These coils are often galvanized or pre-painted to increase resistance to corrosion and weather-related damage.

2. Uncoiling The steel coils are unrolled and fed into the machine. This step is crucial as it ensures a smooth flow of material into the manufacturing process.

3. Forming The heart of the machine, the forming section, consists of rollers that shape the flat sheet into the desired barrel corrugated profile. This is done through a series of carefully calibrated processes that ensure uniformity and precision in the curvature of the sheet.

4. Cutting Once the sheets are formed, they are cut to the specified lengths. The machine typically includes an automatic cutting system that operates in sync with the forming process, ensuring minimal waste and consistent output.

5. Quality Control After cutting, the sheets undergo a quality inspection. This step ensures that each piece meets the required standards for thickness, curvature, and finish.

Advantages of Using Barrel Corrugated Roof Sheet Forming Machines

1. Efficiency The automated nature of these machines allows for high production rates. Manufacturers can produce large quantities of roof sheets in a short period, meeting market demands effectively.

2. Customization Modern forming machines offer the capability to produce sheets in various sizes and profiles. This customization helps builders and architects create designs tailored to specific projects.

3. Durability The machines facilitate the use of high-grade materials, ensuring that the finished products possess excellent tensile strength and durability. This is crucial for roof applications that must withstand the elements over time.

4. Cost-Effectiveness By automating the production process, manufacturers can reduce labor costs and minimize material wastage. The ability to produce high volumes of sheets at lower operational costs is a significant advantage in a competitive market.

5. Sustainability Many manufacturers are focusing on creating energy-efficient machines that minimize waste and reduce energy consumption during the manufacturing process. This aligns with the growing emphasis on sustainable building practices.

Applications of Barrel Corrugated Roof Sheets

The versatility of barrel corrugated roof sheets makes them suitable for a wide array of applications. Their use can be found in

- Residential Homes Adding a unique architectural element to residential roofs. - Commercial Buildings Providing durable roofing solutions for warehouses and commercial spaces. - Agricultural Structures Ideal for barns and storage sheds due to their robust construction. - Industrial Facilities Offering effective roofing for factories, ensuring protection from environmental elements.

Conclusion

Barrel corrugated roof sheet forming machines represent a crucial technology in the construction industry, enabling the efficient production of high-quality roofing materials. With their numerous advantages, including efficiency, customization, and sustainability, these machines not only enhance production capabilities but also contribute significantly to modern architectural designs. As the industry continues to evolve, the importance of such machinery will only grow, solidifying their role in shaping the roofs of tomorrow.