The Evolution and Importance of 50-600% Cable Tray Machines

In the world of industrial manufacturing and electrical infrastructure, the role of cable tray machines is becoming increasingly significant. The term “50-600% cable tray machine” might suggest a range of production capabilities and efficiencies, taking into consideration factors such as material handling, production speed, and output quality. This article delves into the features, advantages, and applications of advanced cable tray machines, emphasizing their role in modern manufacturing processes.

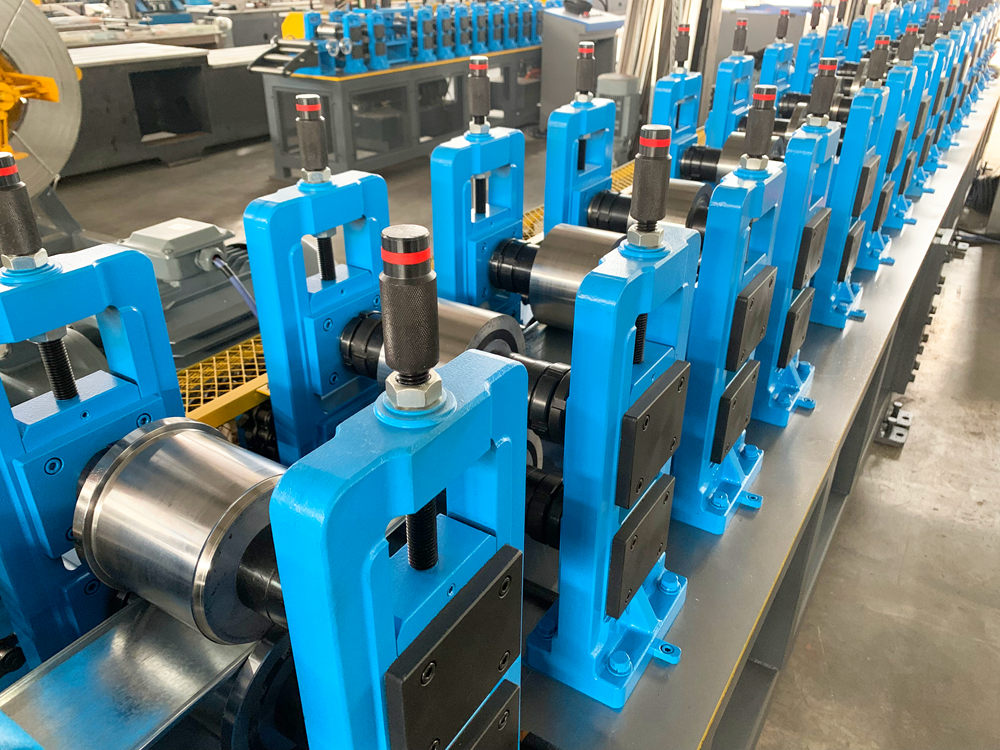

Understanding Cable Tray Machines

Cable tray machines are specialized equipment designed for the production of cable trays, which are essential for supporting insulated electrical wires and cables in various settings such as commercial buildings, manufacturing plants, and outdoor installations. The efficiency and effectiveness of these machines are pivotal for ensuring the organization and safety of electrical systems, thereby reducing the risk of hazards and ensuring compliance with industry standards.

The 50-600% in the name typically refers to the operational flexibility of the machine, indicating its capability to expand or adapt its production capacity based on specific project requirements. This range allows manufacturers to produce a wide array of cable tray sizes, from smaller, more common trays to larger, specialized versions. The adaptability of these machines is crucial in meeting the fast-evolving demands of industries such as construction, telecommunications, and energy.

Key Features of 50-600% Cable Tray Machines

1. Versatile Material Handling Modern cable tray machines can handle various materials, including steel, aluminum, and other composite materials. This versatility ensures that manufacturers can produce cable trays that meet different safety and durability standards.

2. High Production Speeds One of the most compelling features of the 50-600% cable tray machine is its ability to maintain high production speeds while ensuring quality. This efficiency is vital for meeting tight project deadlines and increases overall productivity.

3. Advanced Technology Many of these machines are equipped with cutting-edge technology such as Computer Numerical Control (CNC) systems, which allow for precision in cutting, bending, and assembling trays. This level of automation minimizes human error and maximizes output consistency.

4. Easy Maintenance and Operation Ease of use and low maintenance costs are essential considerations for manufacturers. Most modern cable tray machines are designed for straightforward operation, allowing for quick training of staff and minimizing downtime due to maintenance.

5. Environmental Considerations With growing awareness of environmental concerns, many cable tray machines are designed to minimize waste and energy consumption. Efficient production processes not only benefit the manufacturers economically but also contribute to sustainable development efforts.

Applications and Benefits

The applications of cable trays produced by these machines are vast and varied. They are commonly used in

- Commercial Buildings Providing organized pathways for electrical cables and improving safety and accessibility. - Industrial Plants Supporting heavier electrical systems and ensuring that wiring is kept secure and out of harm’s way. - Telecommunications Facilitating the routing of extensive networking and communication cables.

The benefits extend beyond mere utility. Implementing a state-of-the-art 50-600% cable tray machine can enhance a manufacturer’s reputation by providing high-quality products, promoting workplace safety, and ensuring compliance with regulations.

Conclusion

In conclusion, the 50-600% cable tray machine represents a significant advancement in the production of cable management solutions. Its ability to adapt to a range of manufacturing needs, combined with high efficiency and precision, makes it an invaluable tool in contemporary industrial settings. As the demand for effective electrical infrastructure continues to grow, so too will the importance of these cutting-edge machines. Embracing such technology not only streamlines production processes but also paves the way for safer and more organized electrical systems, ultimately contributing to a more efficient and sustainable future in manufacturing.