The evolution of renewable energy technology continues to surprise and inspire, with photovoltaic (PV) solar systems leading the charge toward a cleaner, more sustainable future. At the heart of many PV solar installations are versatile structures that support solar panels, ensuring their optimal performance — the PV solar brackets. These essential components are often produced using specialized machinery known as the PV solar bracket roll forming machine. Delving into the technology, capabilities, and advantages of these machines reveals their critical role in expanding solar energy use worldwide.

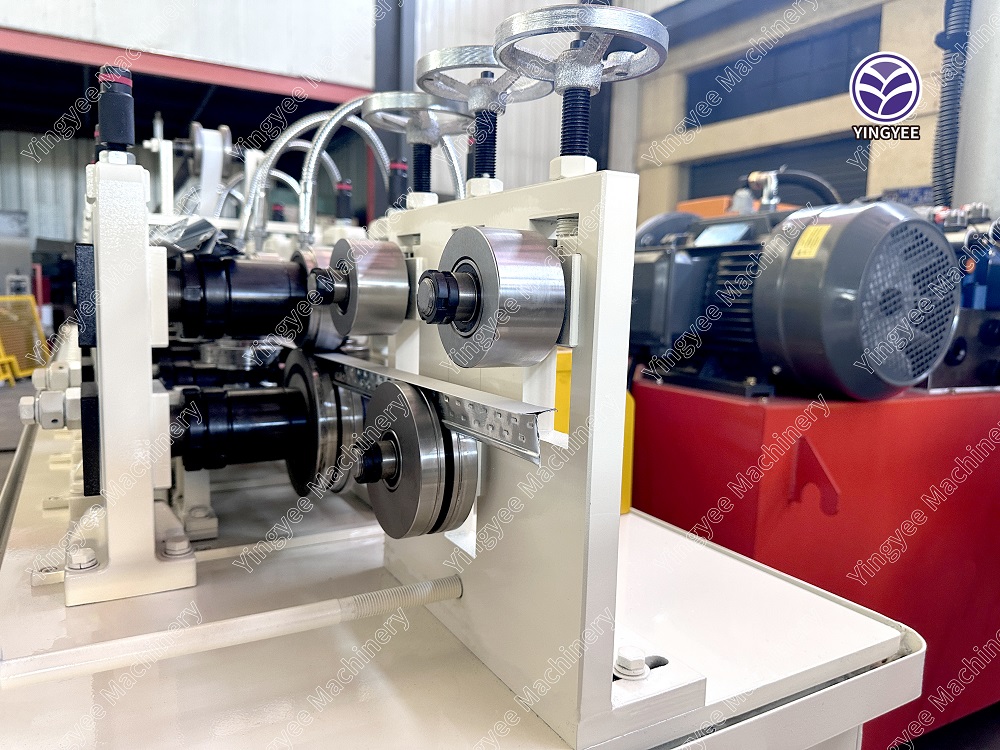

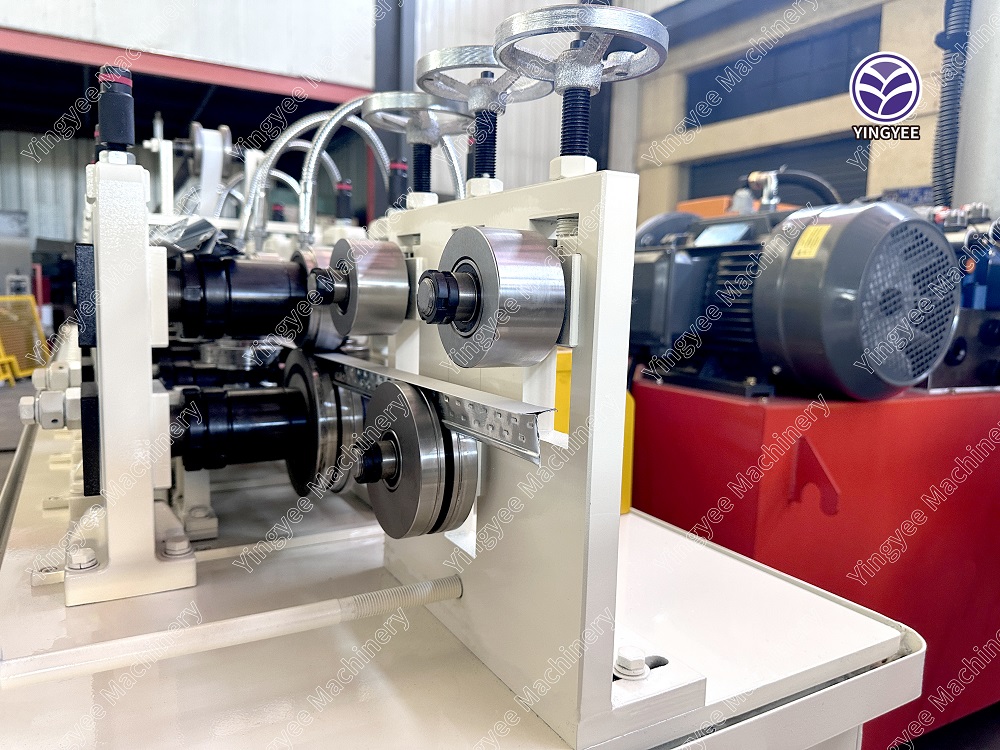

The PV solar bracket roll forming machine is a marvel of modern manufacturing, designed specifically to produce the complex profiles of brackets efficiently and consistently. These machines utilize a series of paired rollers, arranged in sequence, to gradually shape flat sheet metal into the desired form. This process ensures precision in dimensions and integrity in strength, crucial attributes for any structure tasked with supporting solar panels under various environmental conditions.

From an expertise standpoint, the engineering behind roll forming machines is rooted in extensive material science knowledge and advanced mechanical design. Each machine is a testament to precision engineering. The rollers and dies are precisely designed to accommodate the unique geometries of solar brackets, with rapid adjustments possible to cater to different design specifications or materials. This flexibility not only enhances production efficiency but also aligns with industry demands for evolving solar technologies and configurations.

For those involved in the production of PV solar brackets, the reliability and performance of roll forming machines are paramount. Trusted manufacturers utilize high-grade materials and advanced electronics to ensure that their equipment withstands the rigors of constant operation. Moreover, the integration of automation in modern roll forming machines translates to reduced labor costs and minimized human errors, further elevating their appeal in industrial-scale production settings.

Additionally, the latest models come equipped with sophisticated software systems that offer real-time monitoring and diagnostics, enabling operators to troubleshoot issues swiftly, ensuring minimal downtime. Such technological advancements underscore the machine's role as not only a tool of production but a partner in innovation.

pv solar bracket roll forming machine

From an experience perspective,

investing in a PV solar bracket roll forming machine offers numerous operational advantages. The speed and accuracy of roll forming often outpace traditional methods like welding or extrusion, making it a preferred choice for large-scale manufacturers focused on cost efficiencies and productivity. Producing in-house rather than outsourcing bracket fabrication also grants manufacturers more control over quality and supply chain management, bolstering their reputation for delivering reliable, high-quality solar infrastructure components.

Furthermore, the environmental impact of solar energy systems begins with responsible manufacturing processes. Roll forming machines are typically more efficient in material usage, often producing less waste compared to alternative methods. This aligns well with the sustainment ethos intrinsic to the solar energy sector, reducing the carbon footprint associated with bracket production.

Authoritativeness in the realm of roll forming technology is established through adherence to stringent industry standards and continuous innovation. Top-performing machines are often certified by international quality management systems, such as ISO, which assures stakeholders that the equipment meets globally recognized quality benchmarks. Leaders in the manufacture of these machines often contribute to research and development in solar technology, ensuring their solutions remain at the forefront of industrial trends and technological advancements.

Trustworthiness is further established by the proven track record of roll forming machines in enhancing operational efficiencies and supporting large-scale solar deployments. Case studies and testimonials from past implementations provide evidence of the machines' reliability and effectiveness. For decision-makers, the assurance of a well-supported, durable machine that can adapt to various production needs reinforces confidence in their investment decision.

In conclusion, the PV solar bracket roll forming machine stands as a cornerstone of solar infrastructure manufacturing. It embodies the fusion of cutting-edge technology with practical industrial application, serving as an enabler for the widespread adoption of solar energy. Through precision engineering, operational efficiency, and environmental stewardship, these machines not only contribute to the growth of renewable energy but also pave the way for future innovations in sustainable infrastructure development.