Across all our products—from purlin machines to sandwich panel lines—YingYee Machinery combines cutting-edge R&D, stringent quality control, and customer-centric service. Our solutions are designed to boost productivity, reduce operational costs, and adapt to evolving industry trends. Partner with us to equip your business with machinery that not only meets but exceeds global standards, backed by a team committed to your long-term success.

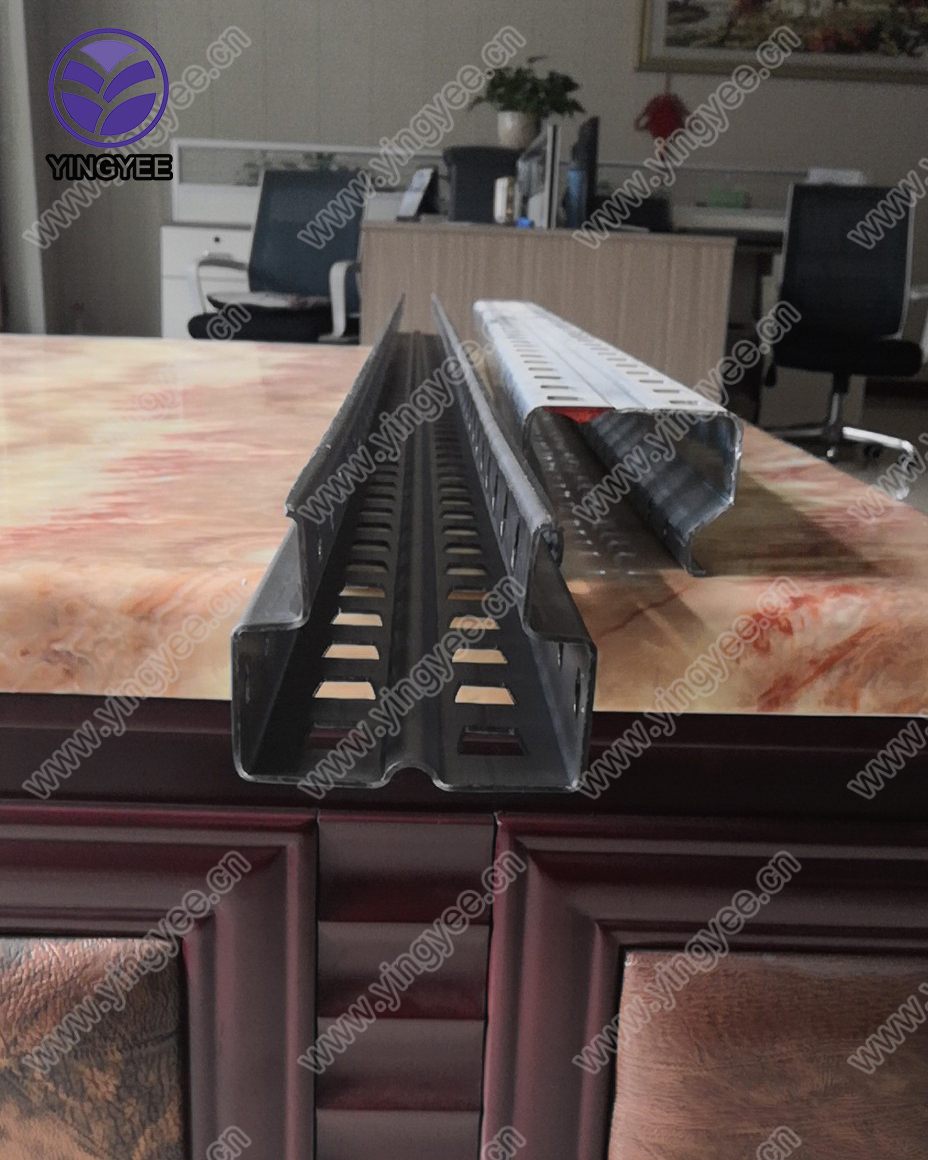

Có thể chọn hai sóng và ba sóng. Độ dày tối đa là 4mm.

Dây chuyền cắt kim loại nhiều kích thước và vật liệu. Dây chuyền sản xuất thông thường này có thể cắt thép mạ kẽm, cán nóng, thép không gỉ có độ dày từ 0,3mm-3mm và chiều rộng tối đa là 1500. Chiều rộng tối thiểu có thể chia thành 50mm. Có thể làm dày hơn và cần tùy chỉnh đặc biệt.

Máy tạo hình giá lưu trữ là dây chuyền sản xuất hoàn toàn tự động, có thể tạo ra giá nặng có độ dày tối đa là 3mm.

Dây chuyền cắt theo chiều dài cho nhiều loại vật liệu với chất lượng tốt, hiệu ứng cắt chính xác. Dây chuyền sản xuất này có thể sản xuất các tấm thép không gỉ, thép cán nóng và thép mạ kẽm có độ dày từ 0,3mm-3mm và chiều rộng tối đa là 1500, với chiều dài tấm ngắn nhất là 500mm. Chiều dài băng tải dài nhất có thể tùy chỉnh.

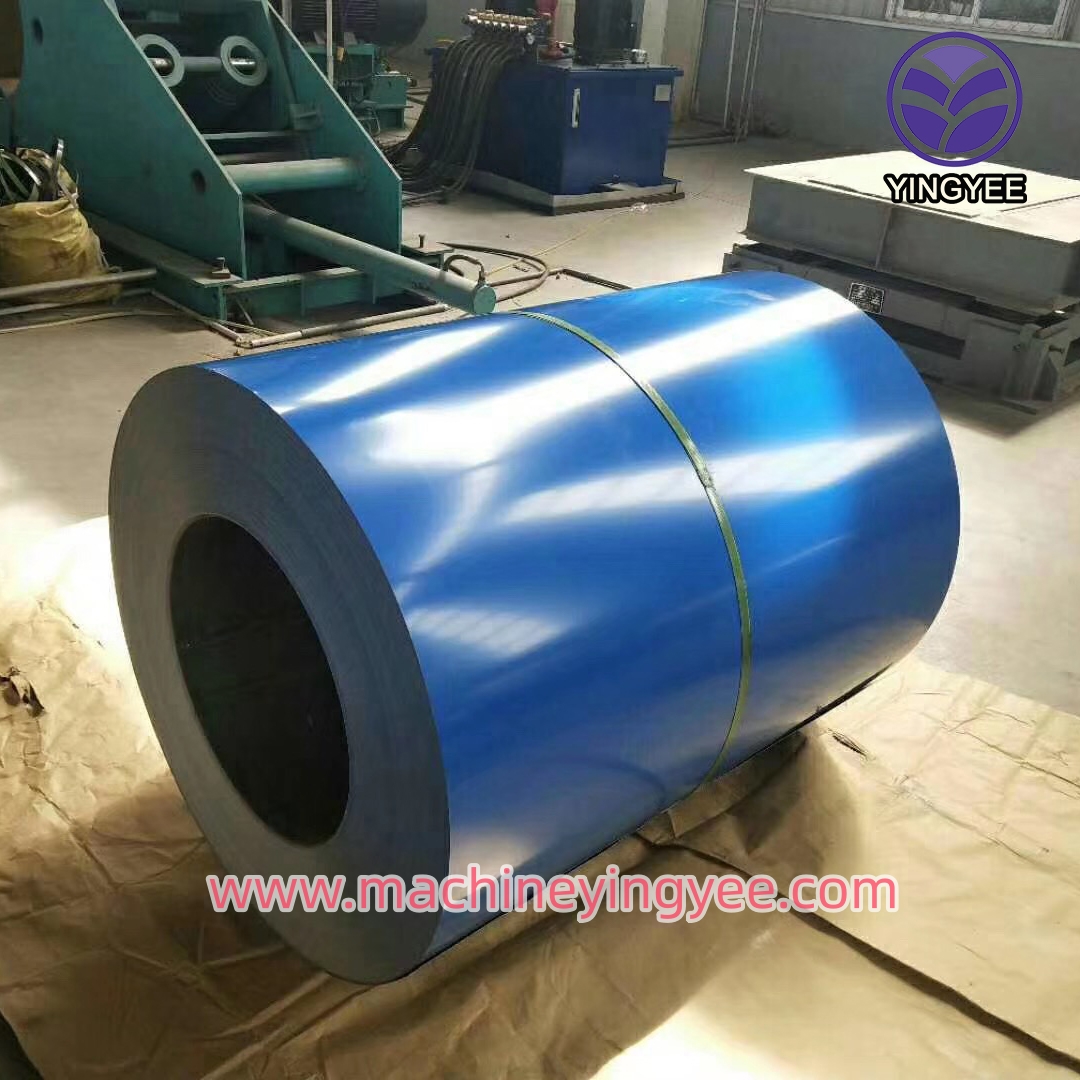

We supply multiple materials, including galvanized coils, pre painted seel coils, steel strip, aluminum zin coils, aluminum coils ect.

Dây chuyền sản xuất hoàn toàn tự động, toàn bộ dây chuyền bao gồm ba máy cho máy T chính, máy T chữ thập và máy góc tường.

There are 10 types UBM120 and UBM240 available, which is more automated.

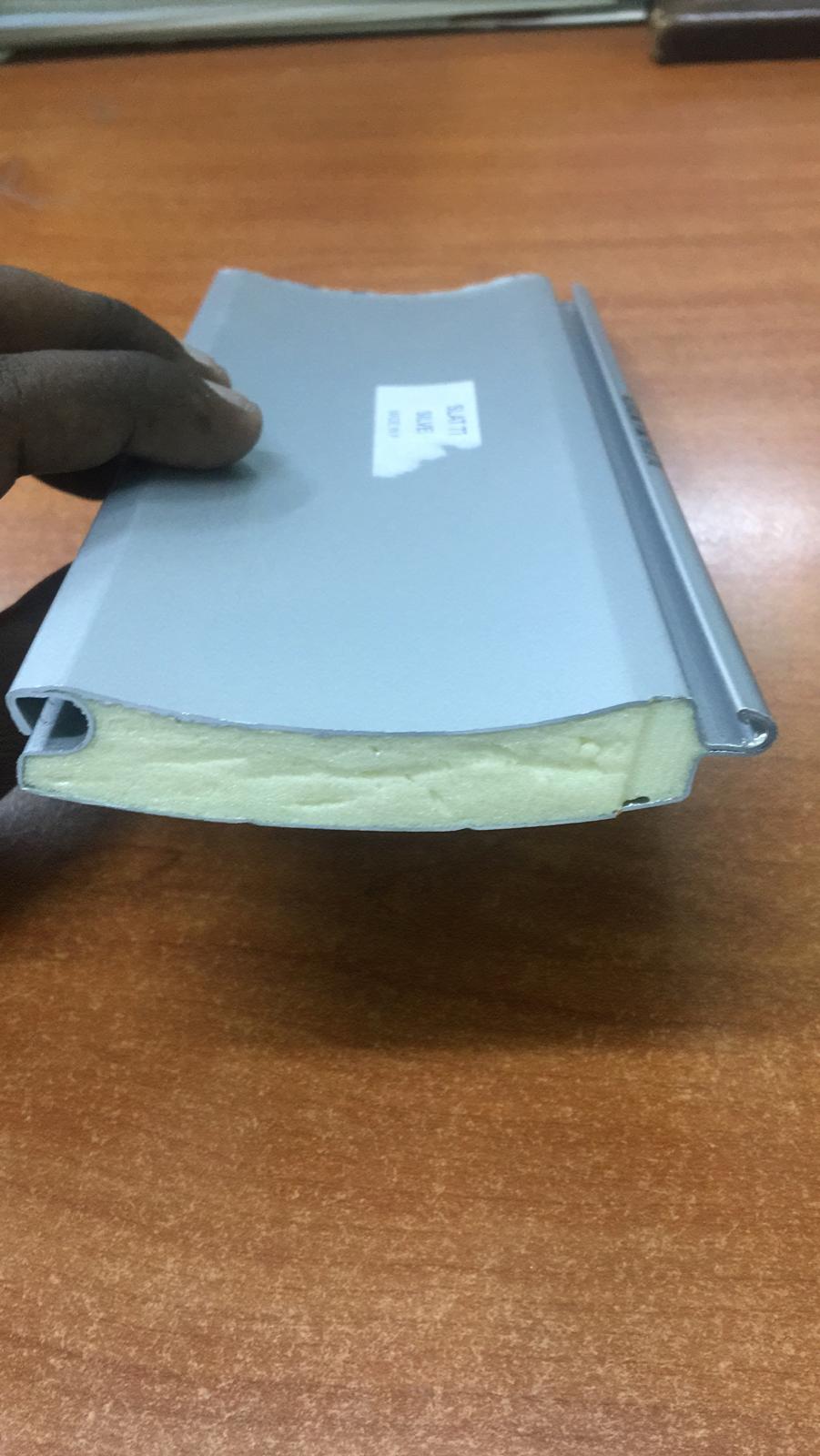

Máy cán tôn PU, hiệu quả tạo hình và phun tốt. Chúng tôi cung cấp máy có hai tốc độ, 15m/phút và 30m/phút tùy chọn.

Chiều dài của toàn bộ dây chuyền sản xuất khoảng 25m và cần có hố đệm.

In the competitive world of metal processing, efficiency and precision are paramount. YingYee Machinery’s Automatic C/Z Purlin Roll Forming Machine stands at the forefront of innovation, delivering unmatched performance for construction and industrial applications. Designed for high-speed production, this machine ensures consistent accuracy in forming C and Z purlins, essential for structural frameworks in warehouses, factories, and commercial buildings.

What sets our machine apart is its fully automated operation, minimizing manual intervention and reducing labor costs. Equipped with a PLC control system, it guarantees seamless adjustments for different specifications, ensuring versatility across projects. Additionally, its robust construction and durable components translate to long-term reliability, even under heavy-duty usage. By choosing our purlin roll forming machine, manufacturers gain a competitive edge—faster production cycles, superior product quality, and reduced material waste.

A durable, weather-resistant roof begins with high-quality materials and precision engineering. YingYee Machinery’s Corrugated/Trapezoid Roof Sheet Forming Machine is engineered to produce roofing sheets with exceptional strength and aesthetic appeal, catering to both residential and industrial sectors. Whether for agricultural buildings, warehouses, or modern architectural designs, this machine delivers uniform corrugation and precise trapezoidal profiles with every run.

Our machine integrates high-efficiency servo systems and advanced hydraulic cutting technology, ensuring clean, burr-free edges and consistent sheet lengths. The user-friendly interface allows operators to switch between profiles effortlessly, reducing downtime. Moreover, its compatibility with pre-painted galvanized steel (PPGI) and aluminum coils ensures versatility in material choices. By investing in this technology, manufacturers can offer clients roofing solutions that combine durability, cost-effectiveness, and rapid installation—key demands in today’s construction market.

For industries requiring high-strength, seamless tubing—from automotive to furniture manufacturing—YingYee Machinery’s Tube Mill High-Frequency Welded Tube Production Line redefines production standards. This state-of-the-art system specializes in crafting straight-seam welded tubes with impeccable weld integrity and dimensional accuracy, meeting stringent international quality benchmarks.

The production line boasts automated coil feeding, precision forming, and high-frequency induction welding, ensuring minimal energy consumption and maximum output. Its real-time monitoring system detects imperfections instantly, guaranteeing defect-free tubes. Furthermore, the modular design allows customization for diameters and thicknesses, catering to diverse industrial needs. By leveraging this technology, manufacturers achieve higher throughput, reduced scrap rates, and superior product consistency—critical factors in maintaining a competitive stance in global supply chains.