The Evolution and Significance of Unistrut Roll Forming Machines

In today's industrial landscape, efficient manufacturing processes are critical to meeting the diverse needs of various sectors. Among these processes, roll forming has emerged as a vital technique for producing specific metal shapes, particularly in the construction and electrical industries. One of the notable applications of roll forming is in the production of Unistrut, a versatile framing system used widely in the support of overhead structures.

What is Unistrut?

Unistrut refers to a brand of metal framing systems that utilize channel-shaped profiles made from steel or aluminum. These profiles provide a robust solution for constructing support systems for electrical conduits, sanitary pipes, and HVAC components. The Unistrut system offers flexibility in design, allowing for easy assembly and customization to meet a wide range of project requirements. Given its widespread use, the manufacturing process of Unistrut must be efficient and precise, which is where roll forming machines come into play.

The Role of Roll Forming Machines

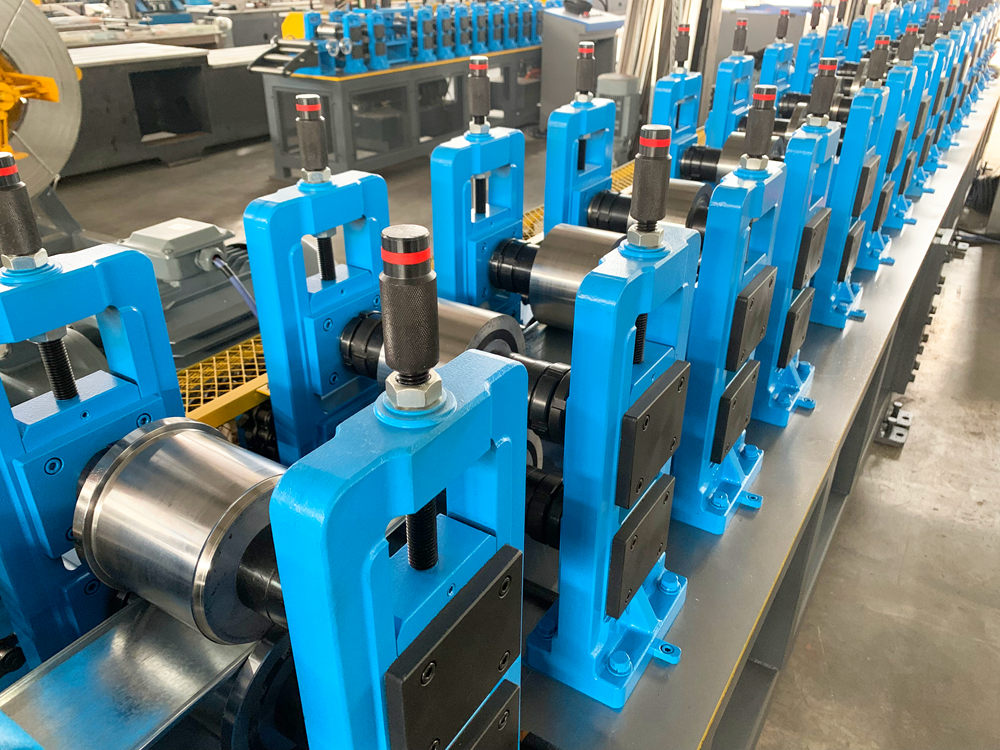

Roll forming machines are specialized equipment designed to shape metal strips into desired profiles through a series of mechanical passes. The metal is fed through a series of rollers, where each roller progressively bends the strip into its final shape. This technique is particularly advantageous for producing long lengths of uniform cross-sections, such as those required in Unistrut applications.

The process begins with the selection of raw materials, commonly cold-rolled or hot-rolled steel. The metal is then cut into strips of the desired width and fed into the roll forming machine. The machine is equipped with various roll stations, each serving a specific purpose in shaping the material. These roll stations are meticulously engineered to optimize the bending and deformation processes, ensuring consistent and high-quality output.

Advantages of Unistrut Roll Forming Machines

1. Efficiency Roll forming is a continuous process, allowing for high production rates and minimizing waste. This efficiency translates into lower production costs and the ability to meet tight project deadlines.

2. Precision Roll forming machines are designed to produce highly precise profiles. The consistency in shape and dimensions is crucial for components used in construction and electrical applications, where safety and reliability are paramount.

3. Versatility Unistrut roll forming machines can be tailored to produce various profiles by adjusting the roll stations. This capability makes it possible to create products that meet the unique requirements of different industries without the need for extensive retooling.

4. Material Efficiency By utilizing materials effectively, roll forming minimizes scrap and lowers overall material costs. The process can handle a variety of metals, including aluminum and galvanized steel, which adds to its adaptability.

5. Reduced Labor Costs The automation of the roll forming process reduces the need for manual labor, thereby decreasing labor costs and minimizing the likelihood of human error.

Future Trends

As industries evolve, so too do the technologies that support them. The future of Unistrut roll forming machines is likely to be shaped by advancements in automation, computer-aided design (CAD), and Industry 4.0 concepts. Integrating smart technologies will enhance the precision of the roll forming process, allowing for better quality control and quicker response times to market demands.

Moreover, as sustainability becomes increasingly important, roll forming machines are likely to adopt more energy-efficient practices and techniques that reduce the carbon footprint. This trend aligns with the growing awareness of environmental responsibility across all sectors, including construction and manufacturing.

Conclusion

Unistrut roll forming machines play a crucial role in the manufacturing of essential components for various industries, particularly in construction and electrical applications. The efficiency, precision, and versatility of these machines make them indispensable tools in modern manufacturing. As technology continues to advance, the roll forming industry is poised for significant evolution, promising even greater capabilities and sustainability for the future. With ongoing innovations, Unistrut will remain a key player in supporting infrastructure development worldwide, underlining the importance of reliable and efficient manufacturing processes.