In the world of industrial manufacturing, the transformation of raw metal into functional components often involves complex procedures and advanced machinery. One such piece of equipment essential in the storage industry is the storage rack roll forming machine. This sophisticated apparatus is integral to the production of storage racks, combining the principles of cold roll forming with state-of-the-art technology to meet diverse industrial needs.

Cold roll forming is a meticulous and highly efficient process used to shape metal into desired profiles. Typically involving long strips of metal, roll forming operates at room temperature, preserving the metal's intrinsic properties while achieving the required shapes and dimensions. This methodology is crucial in producing storage racks that are robust, durable, and capable of supporting substantial loads.

Storage racks play an essential role in modern warehousing and logistics, providing organized and efficient storage solutions. The demand for these racks, particularly in industries such as retail, distribution, and manufacturing, underscores the need for reliable forming equipment that can produce high-quality racks with precision and consistency.

Experience with roll forming equipment highlights several advantages that enhance production efficacy. Firstly, roll forming machines deliver uniform product quality due to their continuous bending of the metal. This uniformity ensures that each storage rack component fits seamlessly with others, promoting structural integrity across the entire rack system. Moreover, the automation facilitated by roll forming machines reduces the reliance on manual labor, significantly cutting down production time and labor costs.

Expertise in cold roll forming technology enables manufacturers to adapt to varying industrial requirements. By adjusting machine settings, producers can create custom profiles tailored to specific weight limits and storage needs. This versatility is particularly beneficial in the storage rack sector, where different industries require racks with varying load-bearing capabilities and dimensions.

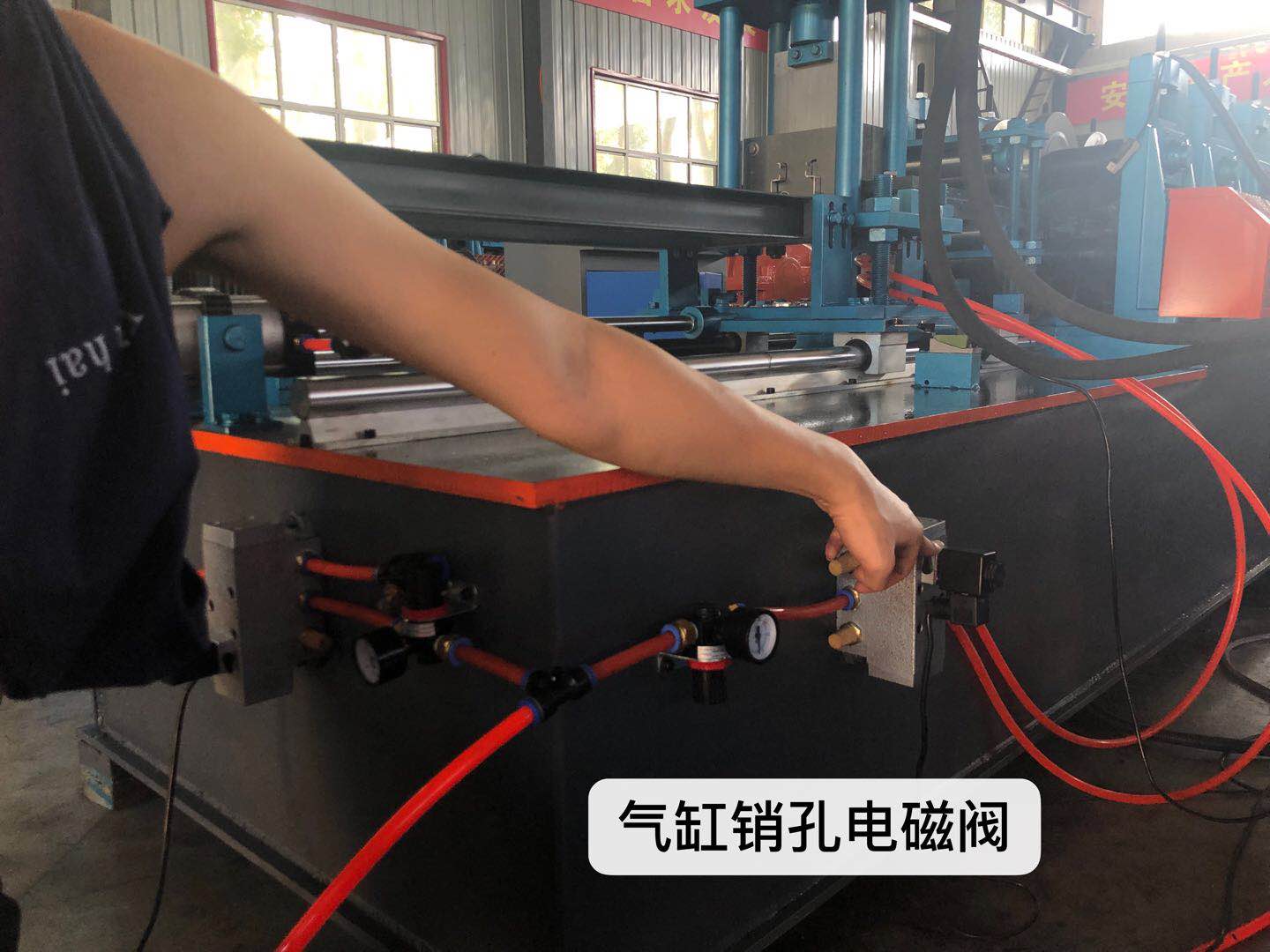

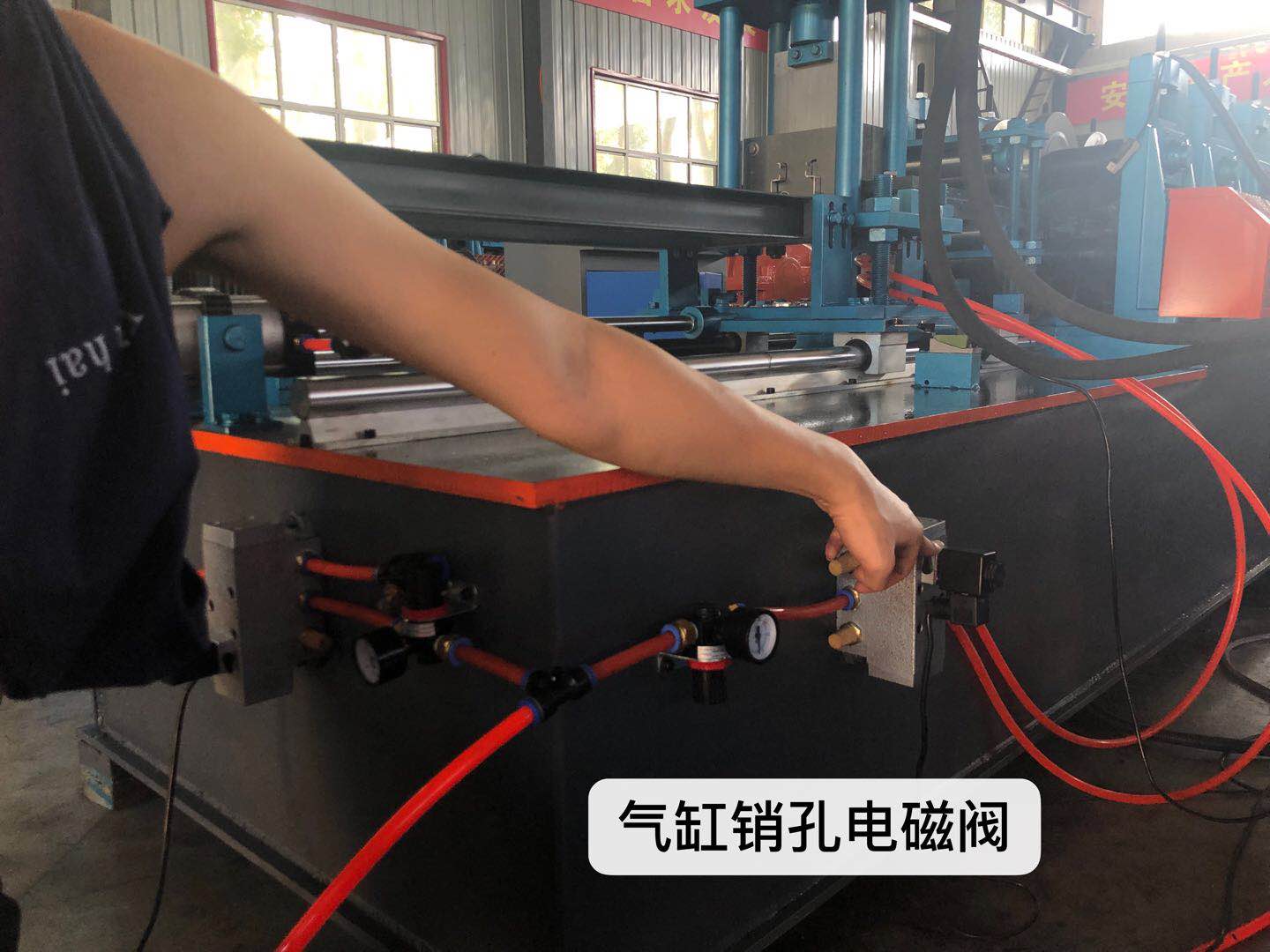

storage rack machine used cold roll forming equipment

Authoritativeness in the field of storage rack production is achieved through ongoing innovation and adherence to quality standards. Leading manufacturers often collaborate with experts in metallurgy and engineering to continually refine their roll forming processes. By incorporating advanced software and analytics, these manufacturers ensure precise control over every phase of the production, from design to final assembly. This commitment to excellence not only bolsters the reputation of storage rack producers but also instills confidence in their clients regarding product reliability and safety.

Trustworthiness, the cornerstone of successful long-term business relationships, is earned through consistent delivery of products that meet or exceed expectations. Customers rely on storage racks to protect their goods and optimize space efficiently — a responsibility that begins with the machinery used in their production. By investing in high-caliber cold roll forming machines, manufacturers demonstrate a commitment to quality and customer satisfaction.

Choosing the right roll forming machine for storage rack production involves careful consideration of several factors. The machine's capacity, speed, and flexibility are critical parameters that impact overall output and efficiency. Additionally, maintenance requirements and energy consumption are essential considerations, influencing operational costs and sustainability.

For businesses looking to invest in storage rack roll forming machinery, it is vital to partner with reputable suppliers who offer not only high-quality equipment but also expert consultation and technical support. Such partnerships can provide invaluable insights into machine operation and maintenance, ensuring that the production line operates smoothly and efficiently.

In conclusion, storage rack roll forming machines represent a blend of precision engineering, innovation, and practicality. By harnessing the power of cold roll forming technology, manufacturers can produce storage solutions that are both robust and reliable. As industries continue to evolve, the demand for high-quality storage racks will persist,

making the role of advanced roll forming equipment more crucial than ever. With a focus on experience, expertise, authoritativeness, and trustworthiness, businesses can capitalize on these versatile machines to gain a competitive edge in the storage industry, ensuring that their products meet the highest standards of quality and performance.