The Process and Importance of Galvanizing Pipe Making Machines

In the realm of industrial manufacturing, galvanizing pipe making machines play a crucial role in ensuring the durability and longevity of metal pipes. These machines are specifically designed to coat steel or iron pipes with a layer of zinc, providing essential corrosion resistance. The process of galvanization not only enhances the mechanical properties of the pipes but also extends their useful life, making them an integral component in various applications such as construction, water supply, and oil and gas industries.

What is Galvanization?

Galvanization is a metallurgical process that involves the application of a protective zinc coating to ferrous metals. The primary purpose of this process is to prevent rust and corrosion, which can significantly weaken the structural integrity of steel materials over time. Zinc acts as a sacrificial anode, corroding in place of the underlying metal, thus ensuring that the pipes maintain their strength and function effectively for years.

The Role of Galvanizing Pipe Making Machines

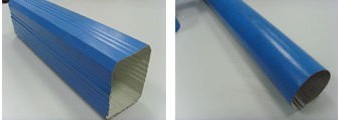

Galvanizing pipe making machines are sophisticated pieces of equipment that automate the galvanization process. They typically consist of various components, including a forming machine, a welding unit, a zinc bath, and a cooling station. The production process begins with raw steel or iron, which is fed into the forming machine to create the desired pipe shape. Once the pipes are formed, they undergo welding to join the edges securely.

After the welding process, the pipes are immersed in a molten zinc bath. This step is critical, as the molten zinc accurately coats the entire surface of the pipe, ensuring maximum protection against environmental factors. The temperature of the zinc bath is carefully controlled, as it needs to be hot enough to allow the zinc to flow and adhere to the metal without damaging its structural integrity.

Once the pipes are coated, they are removed and cooled, allowing the zinc to solidify and bond to the metal surface effectively. The entire process, from forming to cooling, is designed for efficiency and precision, often completed in a continuous production line to meet large-scale demands.

Advantages of Using Galvanizing Pipe Making Machines

The use of galvanizing pipe making machines offers numerous benefits

1. Cost-Effectiveness Although the initial investment in galvanizing equipment might be significant, the long-term savings due to decreased maintenance and replacement costs make it a wise choice. Galvanized pipes last significantly longer than uncoated alternatives.

2. Quality Control Modern galvanizing machines are equipped with advanced technology that allows for precise control over various parameters, ensuring that each pipe meets strict quality standards. This reduces the likelihood of defects and ensures uniformity across production batches.

3. Eco-Friendly Zinc is a naturally occurring metal that is recyclable. The galvanization process is considered environmentally friendly as it reduces the need for replacing pipes frequently, thereby lowering the overall environmental impact.

4. Wide Application Galvanized pipes are used in various applications, including plumbing, agricultural irrigation, and electrical conduits. Their resistance to corrosion makes them suitable for both indoor and outdoor uses, enhancing their versatility.

Conclusion

Galvanizing pipe making machines are a vital investment in the industrial manufacturing sector, particularly for businesses that rely on the production of durable metal pipes. By employing advanced technology in galvanization, manufacturers can ensure the delivery of high-quality, corrosion-resistant pipes that meet the demands of various industries. As infrastructure needs grow and environmental concerns mount, the importance of reliable and long-lasting materials, such as those produced by galvanizing pipe making machines, will undoubtedly continue to rise.