(coil cut to length)

Modern coil cut to length

technology transforms coiled metal sheets into precise flat panels with exceptional dimensional consistency. Contemporary cut to length coil lines integrate advanced servo systems that achieve ±0.005 inch tolerance while maintaining speeds exceeding 400 feet per minute. The transition from manual shearing operations to automated coil processing has reduced material waste by up to 29% industry-wide according to MetalForming Magazine's 2023 efficiency report. Beyond basic panel creation, coil processing systems provide the foundational material preparation for automotive body panels, appliance housings, and structural building components.

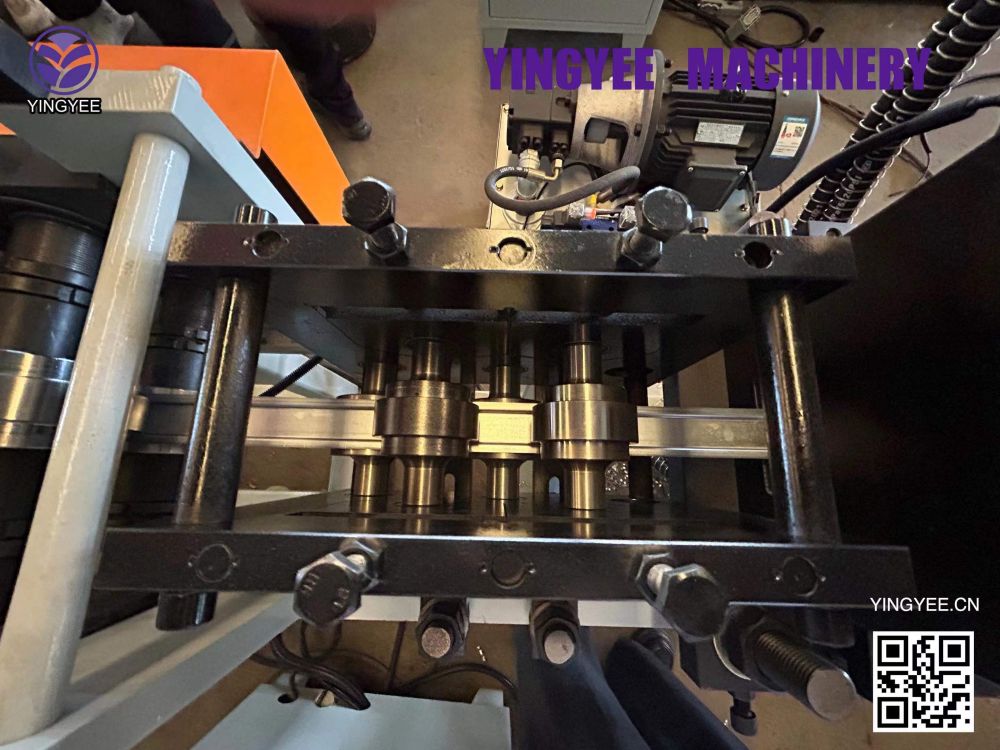

Third-generation CTL systems now feature synchronous servo-driven components that coordinate uncoiling, straightening, feeding, and shearing operations within milliseconds. This synchronization allows the automatic high speed metal steel coil cut to length production line to maintain 600 m/min processing speeds without vibration-induced dimensional errors. Precision ground cutter heads with laser-aligned blade clearance provide 95% longer service intervals than conventional hydraulic systems. Modern European designs incorporate AI-enabled predictive maintenance modules that analyze vibration patterns and temperature fluctuations to preempt component failures, increasing uptime averages to 97.2% according to manufacturing benchmarks.

| Manufacturer | Cutting Speed (m/min) | Tolerance (mm) | Max Coil Weight (tons) | Energy Efficiency | Tool Change Time (min) |

|---|---|---|---|---|---|

| Eurotech CoilSys | 90 | ±0.08 | 45 | 22% savings | 7 |

| American SteelPro | 75 | ±0.12 | 30 | Standard | 15 |

| Asiatech Precision | 85 | ±0.05 | 50 | 18% savings | 5 |

The comparison data indicates substantial variation in operational capabilities. Superior tolerance ratings below ±0.1mm consistently correlate with laser-guided measurement systems, while quick tool change implementations reduce equipment downtime by 63% in high-volume production environments.

Leading engineering teams now offer customizable coil cut to length line configurations based on end-product specifications. For heavy-gauge applications exceeding 10mm thickness, manufacturers implement dual-servo shear mechanisms producing 3800 kN cutting force without velocity loss. Clients processing thinner gauge materials (0.4-2.0mm) benefit from vacuum handling systems that eliminate surface marring during material transfer. Current market availability includes:

Automotive suppliers implementing next-generation coil cut to length equipment report measurable operational improvements. Volkswagen's Chattanooga facility reduced panel scrap rates by 37% after upgrading to servo-electric processing lines, while General Appliances Ltd. achieved 19% higher output using the same floor space after installing a compact cut to length coil line with vertical integration. Commercial construction materials producer Metaloft Inc. attributes their ISO 9001:2015 certification partly to dimensional consistency achieved through their coil processing technology. These documented outcomes validate engineering estimates projecting ROI within 26 months even for premium systems.

Prospective purchasers should evaluate coil processing machinery against seven critical parameters:

Operators should verify that maximum cutting force exceeds their thickest material requirements by at least 25% to prevent premature wear. Most manufacturers offer material testing demonstrations - an essential step before procurement decisions.

Reimagined coil processing systems incorporate two transformative advances: Permanent magnet servo motors now reduce power consumption by up to 45% compared to conventional induction motors driving coil processing equipment. Simultaneously, smart regeneration modules capture and reuse braking energy during the cyclic operation of a coil cut to length line. Leading manufacturers have committed to ISO 14064 compliant manufacturing processes that reduced carbon emissions by 31% between 2018-2023. The convergence of precision mechanics with sustainable engineering ensures that modern cut-to-length systems remain foundational to efficient metal fabrication industries.

(coil cut to length)

A: A coil cut to length line is an industrial system designed to uncoil, flatten, shear, and stack metal coils into precise flat sheets. It automates the conversion of large steel or metal coils into smaller, ready-to-use panels. This equipment ensures dimensional accuracy while reducing manual labor.

A: Automatic high-speed lines prioritize rapid processing with PLC-controlled precision cutting, achieving speeds over 150m/min. They include servo-driven feeders, automatic stacking systems, and defect-detection sensors. These features maximize output while minimizing material waste.

A: It enables mass production of consistently sized panels with smooth, burr-free edges. Automated operation ensures uniform thickness and reduces material handling risks. This directly improves assembly efficiency for applications like roofing or automotive parts.

A: Major users include construction (roofing/siding panels), appliance manufacturing (housings), and automotive (chassis components). HVAC duct producers and metal furniture manufacturers also depend on these systems for precision-cut sheet materials.

A: Key considerations include material thickness (0.2-6mm typical), coil width capacity (600-2000mm), cutting tolerance (±0.1mm), and line speed. Also evaluate automation levels, tool-change systems, and compatibility with materials like galvanized steel or aluminum.