The Importance of Standing Seam Machines in Modern Construction

In the realm of modern construction, the choice of materials and techniques is crucial to ensuring durability, aesthetics, and overall efficiency. Among the variety of roofing and cladding systems available, standing seam metal roofs have emerged as a favorite due to their numerous advantages. Driving the effectiveness of this roofing system is the standing seam machine, a pivotal tool in the metalworking industry.

A standing seam metal roof is characterized by its vertical panels that interlock at the seams, creating a clean, streamlined appearance. This design not only enhances the visual appeal of the structure but also contributes to its performance. The seams are raised above the roofing surface, which minimizes the risk of water infiltration and offers improved wind resistance. However, to achieve these optimal characteristics, precision in manufacturing is critical, and that is where standing seam machines come into play.

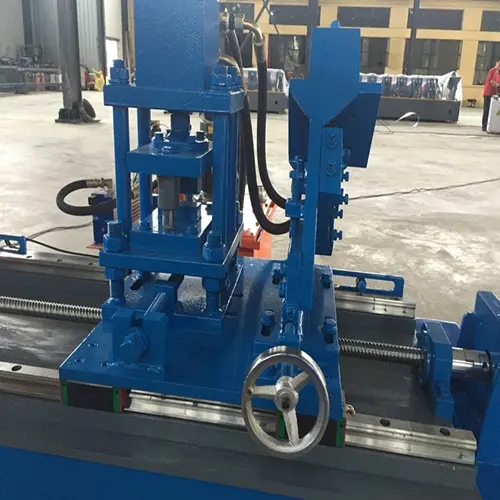

Standing seam machines are specialized equipment used to form and assemble metal roofing panels. These machines can produce panels in various widths and lengths, catering to the specific needs of each project. By utilizing a standing seam machine, contractors can ensure a high level of consistency and quality in their metal products. The machines process metal sheets, often made from materials like aluminum or steel, bending and shaping them into the desired profile with precision.

One of the primary advantages of using a standing seam machine is its ability to enhance productivity. Traditional roofing methods may require numerous manual processes, often resulting in inconsistencies and increased labor costs. With standing seam machines, the automation of panel fabrication significantly reduces the time needed for installation. This efficiency allows contractors to complete projects faster, leading to higher turnover rates and improved profits.

Moreover, standing seam machines are equipped with advanced technology that allows for customization. Builders can create panels of varying heights and widths, accommodating different architectural designs and preferences. This versatility is particularly beneficial for unique projects that require bespoke solutions. Furthermore, the ability to manufacture on-site means that waste material is minimized, promoting environmentally-friendly practices within the construction sector.

In addition to speed and customization, standing seam machines also promote structural integrity. The precision engineering involved in the fabrication process ensures that panels fit together seamlessly, reducing potential weak points where leaks could occur. Furthermore, with the option for continuous panel lengths, there are fewer seams, which minimizes the chances of water ingress during heavy rain. This characteristic is particularly critical in regions prone to adverse weather conditions, where roofing durability is paramount.

As sustainability becomes an increasingly important factor in construction, the use of metal roofs, including those produced by standing seam machines, offers significant environmental benefits. Metal is a recyclable material, making it a more sustainable choice compared to traditional asphalt shingles. Additionally, standing seam roofs are often designed with energy efficiency in mind. Many are available with reflective coatings that reduce heat absorption, contributing to cooler building temperatures and lower energy costs.

In conclusion, standing seam machines play a vital role in the modern construction industry, particularly in the production of standing seam metal roofs. Their ability to enhance productivity, ensure precision, and offer customization makes them an indispensable tool for contractors. With the added benefits of environmental sustainability and structural integrity, it's clear that standing seam machines represent the future of roofing solutions. As the construction landscape continues to evolve, embracing these innovative technologies will be critical for success.