Steel Cable Tray Making Roll Forming Machine

In the modern industrial landscape, efficient manufacturing processes are crucial for meeting the ever-increasing demand for electrical infrastructure components. One such essential component is the steel cable tray, which supports and organizes the myriad of cables in commercial and industrial settings. The production of these cable trays has been significantly optimized through the use of roll forming machines.

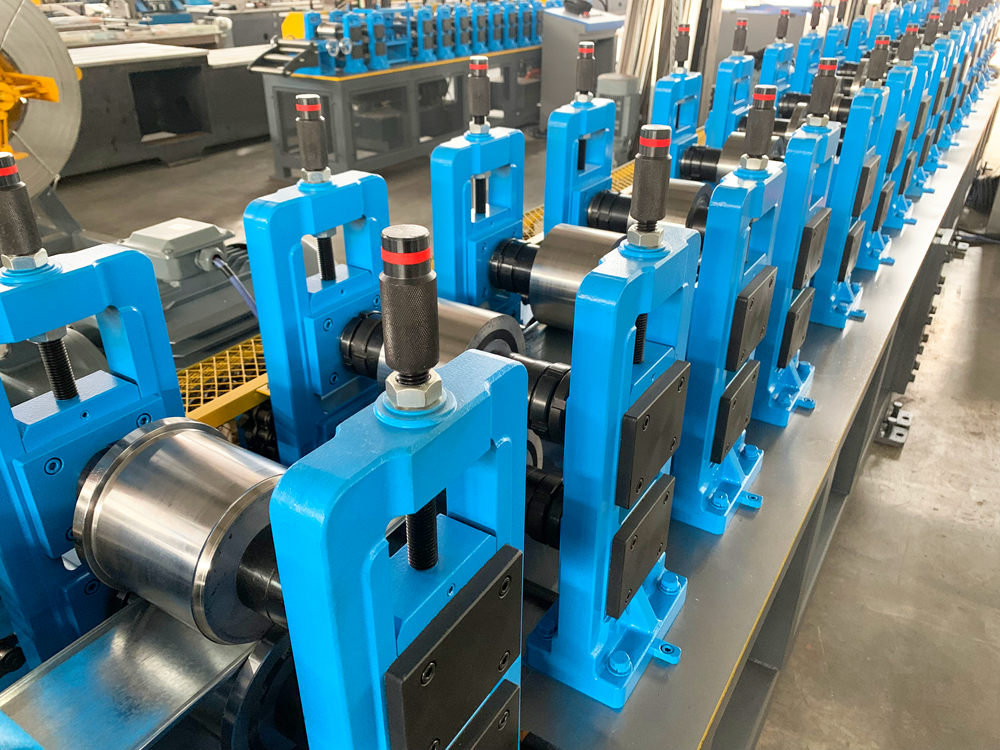

A steel cable tray making roll forming machine is engineered to transform flat steel sheets into precisely shaped cable trays through a continuous bending process. This machine operates by feeding raw steel coils into the roll forming line, where they are progressively shaped by a series of rollers. Each roller applies pressure to the steel, gradually transforming it into the desired profile that meets specific industry standards.

The advantages of using roll forming technology in the production of steel cable trays are manifold. First and foremost, the process is highly efficient. It allows for high-speed production with minimal waste, as the material is continuously fed and shaped without significant interruption. This is particularly important in times of increased demand and tight deadlines.

Moreover, roll forming machines are renowned for their ability to produce uniform and high-quality products. The precision of the rollers ensures that each cable tray has consistent dimensions and strength characteristics. This uniformity is critical, as it directly impacts the installation and usage of the trays in various applications.

Another significant benefit of steel cable tray making roll forming machines is their versatility. These machines can be designed to produce a wide range of tray sizes and profiles, accommodating various installation requirements. Customization options allow manufacturers to tailor the production process to meet specific client needs, enhancing their competitive edge in the market.

Additionally, advancements in technology have led to the integration of automation and control systems in roll forming machines. This integration not only streamlines the production process but also improves safety and reduces labor costs. Operators can monitor and adjust parameters in real-time, ensuring optimal performance and product quality.

In conclusion, steel cable tray making roll forming machines are a vital asset in the manufacturing of electrical infrastructure components. Their efficiency, precision, versatility, and incorporation of modern technology make them indispensable in meeting the needs of today’s fast-paced industrial environments. As industries continue to evolve, these machines will play a pivotal role in shaping the future of electrical cable management solutions.