The roller shutter door panels forming machine is a revolutionary tool in the construction and manufacturing industries, offering enhanced efficiency, precision, and customization options that traditional methods simply cannot match. With an increasing demand for security and aesthetic appeal, roller shutter doors have become a preferred choice for both commercial and residential buildings. Understanding the capabilities and advantages of roller shutter door panels forming machines can significantly benefit manufacturers and end users alike, fostering a more robust and reliable production process.

In the realm of construction, precision is paramount. The roller shutter door panels forming machine excels in this area by providing consistent, high-quality outputs. These machines are equipped with advanced technology capable of producing panels with exact measurements and uniformity, ensuring that each door panel fits perfectly and functions optimally. This level of precision minimizes errors during installation and reduces the need for costly adjustments or replacements, thereby increasing overall efficiency.

Additionally, the automation offered by these machines significantly speeds up the production process. Unlike manual methods, where human error and fatigue can lead to inconsistencies and delays, roller shutter door panels forming machines operate continuously with minimal supervision. This results in a higher production rate, allowing manufacturers to meet tight deadlines and accommodate larger orders without compromising on quality. The combination of speed and precision also translates into cost savings, as labor costs are reduced and material wastage is minimized.

Customization is another significant advantage of using roller shutter door panels forming machines. In today’s market, the ability to tailor products to individual specifications is a critical competitive edge. These machines can be programmed to produce a variety of panel designs, sizes, and materials, catering to the specific needs of clients. Whether for industrial warehouses requiring robust security panels or chic retail stores in need of a stylish front, the versatility of these machines ensures that manufacturers can provide bespoke solutions that meet diverse customer demands.

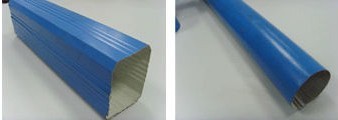

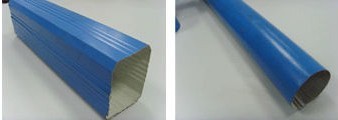

roller shutter door panels forming machine

From an expertise standpoint, operating a roller shutter door panels forming machine requires a blend of technical knowledge and hands-on experience. Manufacturers often invest in training programs to ensure that their operators are well-versed in the latest technological advancements and safety protocols. Skilled operators are essential for maintaining the machine’s performance and prolonging its lifespan, as routine maintenance and quick troubleshooting can prevent minor issues from escalating into costly repairs.

When it comes to authoritativeness, investing in a state-of-the-art roller shutter door panels forming machine signals a commitment to quality and innovation. Manufacturers who utilize these machines are often seen as industry leaders, capable of delivering cutting-edge products that meet the highest standards. This reputation not only attracts more business but also fosters long-term relationships with clients who value reliability and excellence.

Trustworthiness in manufacturing is built on a foundation of quality assurance and customer satisfaction.

Roller shutter door panels forming machines play a crucial role in this regard by ensuring that each panel is produced with impeccable accuracy. The consistency and durability of the panels bolster customer confidence, knowing that their investment is protected by a product that will stand the test of time. For manufacturers, this trust translates into repeat business and referrals, further solidifying their position in the market.

In conclusion, the roller shutter door panels forming machine is an indispensable asset for manufacturers seeking to improve their production capabilities and competitiveness. By offering unparalleled precision, speed, and customization options, these machines not only enhance the efficiency of manufacturing processes but also uphold the highest standards of quality and innovation. For businesses looking to establish themselves as leaders in the industry, investing in this technology is a strategic move toward achieving sustainable growth and customer satisfaction.