High Precision Straightening Machines Revolutionizing the Leveling Process

In the manufacturing landscape, precision and accuracy are paramount. One of the most crucial steps in ensuring that metal components meet stringent specifications is the straightening process. High precision straightening machines, also known as leveling machines, have emerged as essential tools that optimize this process, enhancing both product quality and production efficiency.

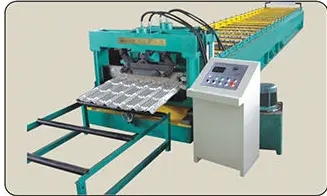

High precision straightening machines are designed to straighten and level materials such as steel sheets, plates, and tubes. The main objective of these machines is to eliminate distortions and deformations caused by various processes like cutting, welding, or heat treatment. These machines utilize advanced technologies and engineering techniques to achieve a level of accuracy that was previously unattainable in conventional methods.

One of the key features of high precision straightening machines is their ability to deliver consistent results. Equipped with sophisticated control systems and sensors, these machines can detect minute variations in the material's surface and automatically adjust the force applied during the straightening process. This ensures that every piece meets the required specifications, reducing the likelihood of defects and subsequent rework, which can be costly and time-consuming.

Moreover, the use of high precision straightening machines contributes to significant time savings in the production process. Traditional straightening methods often involve manual labor and can be labor-intensive, leading to longer turnaround times. In contrast, automated straightening machines can process components quickly and efficiently, allowing manufacturers to increase their output without compromising quality. This efficiency is particularly advantageous in industries where high demand and rapid production cycles are the norm.

In addition to increased efficiency, high precision straightening machines also improve the overall durability and reliability of the final product. Properly leveled materials are crucial for the structural integrity of manufactured components, especially in industries like automotive, aerospace, and construction, where safety is paramount. By ensuring that materials are perfectly straightened, manufacturers can improve the performance and lifespan of their products, leading to higher customer satisfaction and reduced warranty claims.

Furthermore, the adoption of high precision straightening technology supports the ongoing effort towards sustainable manufacturing. By minimizing waste and reducing the need for additional processing steps, manufacturers can lower their resource consumption and environmental footprint. This aligns with the growing emphasis on sustainability in manufacturing practices, appealing to an increasingly conscientious market.

In conclusion, high precision straightening machines play a vital role in modern manufacturing processes. Their ability to deliver accurate, efficient, and reliable straightening solutions not only enhances product quality but also streamlines production operations. As industries continue to evolve, these machines will undoubtedly be at the forefront of innovation, driving advancements in precision engineering and manufacturing excellence.