The Evolution and Importance of Drywall Making Machines

Drywall, also known as gypsum board or plasterboard, is a vital component in modern construction, providing a quick and efficient way to create walls and ceilings. This essential material allows for faster build times and improved building aesthetics. At the heart of drywall production is the drywall making machine, a technological advancement that has revolutionized the construction industry.

The Basics of Drywall Production

Drywall is primarily made of gypsum, a mineral that is abundant and inexpensive. The production process begins with the mining and processing of gypsum, which is then mixed with water and additives to create a slurry. This slurry is sandwiched between layers of heavy paper or fiberglass, compressed, and dried to create rigid sheets of drywall. The efficiency of this process is largely determined by the machinery used, leading to the development of modern drywall making machines.

Components of a Drywall Making Machine

A typical drywall making machine consists of several key components

1. Feeding System This part of the machine is responsible for delivering raw materials like gypsum, water, and additives into the mixing chamber. It needs to be precise and efficient to ensure constant production flow.

2. Mixing Chamber Here, the raw materials are blended into a smooth slurry. The mixing process must be carefully monitored to achieve the desired consistency, which directly affects the quality of the final product.

3. Forming Section After mixing, the slurry is poured onto a conveyor that shapes it into sheets. This section includes molds and rollers that define the thickness and size of the drywall panels.

4. Drying Chamber Once formed, the sheets pass through a drying chamber where they are exposed to controlled heat. This step is crucial for removing moisture and solidifying the drywall.

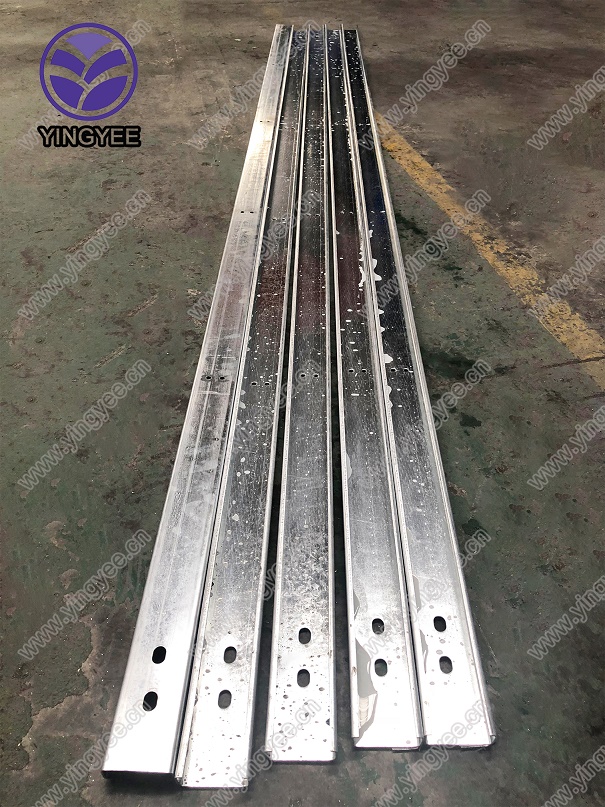

5. Cutting Unit Following the drying process, the large sheets of drywall are cut into standard sizes. This part of the machine must be configured for various dimensions to cater to different construction needs.

6. Packaging System Finally, the finished sheets are stacked, wrapped, and prepared for shipment. Efficient packaging is essential for preventing damage during transportation.

Technological Advancements

The evolution of drywall making machines has been marked by significant technological advancements. Automation and computerization have improved production efficiency, consistency, and safety. Modern machines are equipped with sensors and control systems that monitor every stage of production, reducing waste and minimizing manual labor.

Moreover, innovations in materials handling and energy-efficient dryers have made the production process more sustainable. Manufacturers are now focusing on reducing their carbon footprint by optimizing energy consumption and utilizing eco-friendly materials. This commitment to sustainability not only meets regulatory requirements but also appeals to environmentally conscious consumers.

The Economic Impact

The drywall making machine industry plays a crucial role in the overall construction market. As urbanization continues to rise, the demand for residential and commercial buildings increases, and so does the need for drywall. The production efficiency brought by advanced drywall machines helps manufacturers keep pace with this growing demand while maintaining cost-effectiveness.

Additionally, the global market for drywall is on the rise, driven by construction booms in developing countries and renovation projects in established markets. This growth translates to job creation in manufacturing, distribution, and construction sectors, significantly contributing to economic development.

Conclusion

In conclusion, drywall making machines are indispensable in the construction industry. They streamline the manufacturing process, ensuring the efficient production of high-quality drywall that meets the needs of various construction projects. As technology continues to evolve, these machines will likely become even more efficient and environmentally friendly, ensuring that the drywall production industry keeps pace with global demands. With the constant push for innovation and sustainability, the future of drywall making machines looks promising, marking a significant chapter in building construction history.