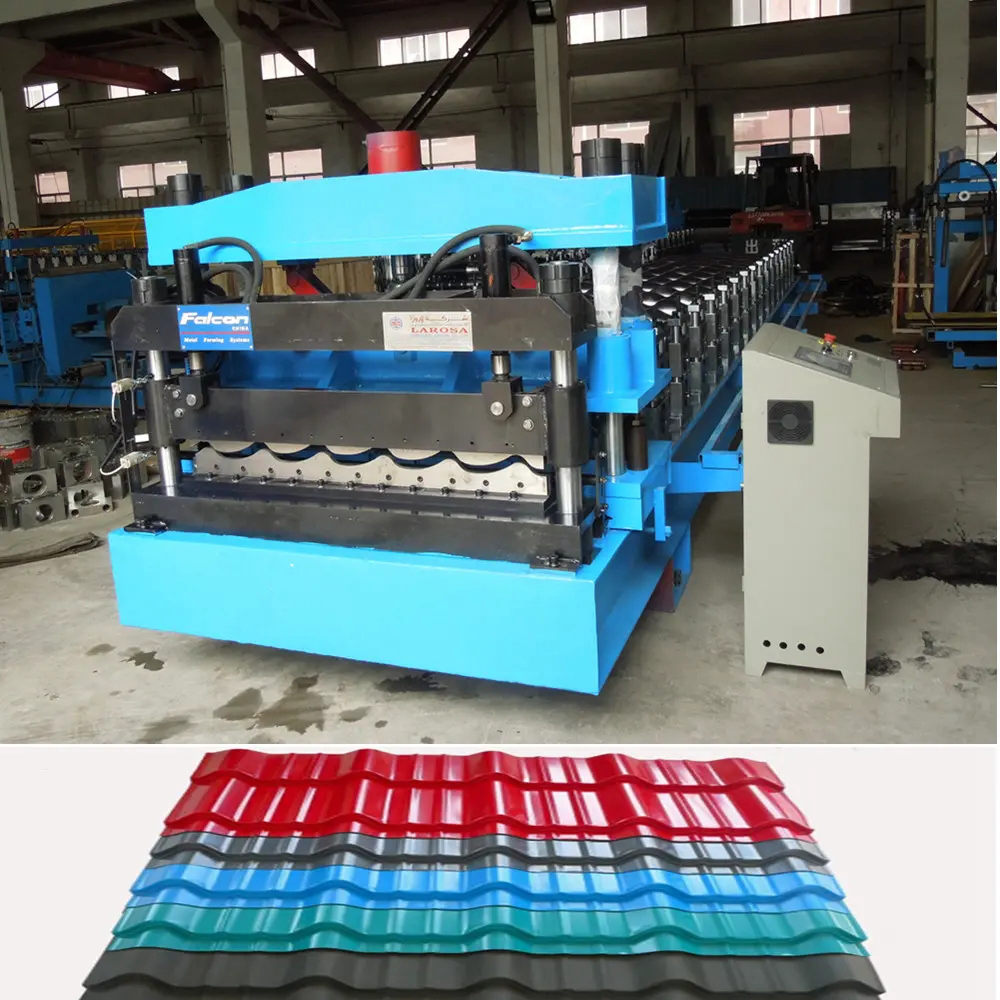

Double Layer Roof Sheet Forming Machine Revolutionizing the Roofing Industry

In the construction and roofing industry, the demand for efficient and versatile manufacturing equipment is ever-growing. One such innovation that has gained significant attention is the double layer roof sheet forming machine. This advanced machinery is designed to produce roof panels and sheets that can be used in various applications, significantly enhancing the productivity and efficiency of roofing manufacturers.

Understanding the Double Layer Roof Sheet Forming Machine

The double layer roof sheet forming machine is a specialized piece of equipment that is capable of producing two different types of roofing sheets simultaneously. It is engineered to save space, reduce labor costs, and increase production output by allowing manufacturers to create two distinct profiles without the need for multiple machines. This versatility makes it an indispensable asset for manufacturers aiming to meet diverse customer needs.

The basic operation of the machine involves feeding coiled metal sheets into the forming system. Once the raw material is in place, the machine employs rollers to shape and cut the sheets into the desired profiles. The two layers can be produced consecutively or concurrently, depending on the machine design. Additionally, most modern double layer machines are equipped with computer numerical control (CNC) technology, which enhances precision and allows for greater customization.

Key Features and Benefits

1. Space Efficiency Traditional methods of roofing sheet production often require multiple pieces of machinery to achieve different profiles. The double layer roof sheet forming machine combines these capabilities into one compact unit, optimizing factory floor space.

2. Increased Productivity With the ability to produce two types of sheets in one process, manufacturers can significantly boost their output. This efficiency allows them to fulfill larger orders more rapidly, thereby improving their competitive edge in the market.

3. Cost-Effectiveness Investing in a double layer forming machine can lead to substantial cost savings. Rather than purchasing separate machines for different profiles, manufacturers can streamline their production process, lower labor costs, and reduce maintenance expenses.

4. Versatility The ability to create a variety of roofing sheets—such as corrugated, trapezoidal, or tile profiles—makes this machine ideal for different market segments. Whether it's residential buildings, commercial projects, or industrial facilities, the options are nearly limitless.

5. Customization The advanced technology used in these machines allows for customization according to client specifications. Whether clients require unique dimensions, colors, or finishes, manufacturers can meet specific demands without compromising quality or speed.

6. Quality Assurance Modern double layer roof sheet forming machines are designed to maintain consistent quality throughout the production process. With precise engineering and quality control measures, manufacturers can ensure that the sheets produced do not warp, deform, or have defects.

Applications in the Industry

The versatility of double layer roof sheet forming machines makes them suitable for various applications. They are commonly used in the construction of residential homes, commercial buildings, warehouses, and agricultural structures. Additionally, their ability to produce aesthetically pleasing and durable roofing solutions makes them a popular choice among architects and builders.

Furthermore, the roofing materials produced from these machines are often lightweight, making them easier to transport and install. This feature is particularly appealing in regions where labor costs are high, as it can significantly reduce both transportation and installation times.

Conclusion

The double layer roof sheet forming machine is a transformative tool in the roofing manufacturing sector. By offering space efficiency, increased productivity, cost savings, versatility, customization, and quality assurance, it empowers manufacturers to meet the evolving demands of the construction industry. As the market continues to expand, adopting such innovative machinery will be crucial for businesses looking to stay competitive and deliver high-quality roofing products to their clients. In the dynamic landscape of construction, investing in advanced technology like the double layer roof sheet forming machine is an essential step toward future success.