Roof Tile Production Line An Overview

The roof tile production line is a critical component in the construction industry, ensuring the availability of durable and aesthetically pleasing roofing materials. This automated system enhances efficiency, reduces labor costs, and maintains consistent high-quality output in roof tile manufacturing.

At the forefront of a roof tile production line is the material preparation stage. Raw materials typically include clay, concrete, or advanced composites, which are processed to achieve the desired consistency. In modern production lines, these materials are blended with additives to enhance durability and weather resistance. This initial step is crucial as the quality of raw materials directly impacts the final product's performance.

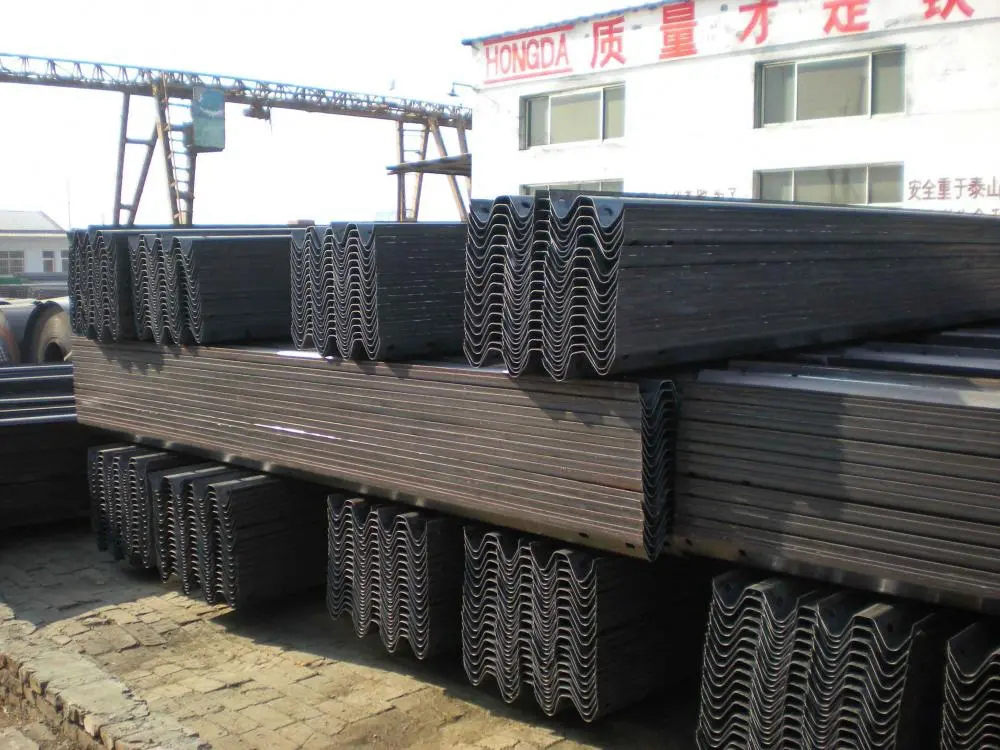

Following material preparation, the next phase involves molding. The processed material is fed into molds that shape the tiles into their final design. Advanced technologies like hydraulic presses or extrusion systems ensure precise shaping, allowing for various tile profiles, including interlocking and flat designs. This versatility caters to diverse architectural styles and customer preferences.

Once molded, the tiles undergo a drying process. This stage is essential to remove moisture, which could compromise the integrity of the tiles during firing. Utilizing controlled environments, manufacturers ensure that the drying process is uniform and efficient, minimizing the risk of cracking or warping.

The firing process follows drying, where the tiles are subjected to high temperatures in kilns. This critical step enhances the strength and durability of the roof tiles, making them resistant to environmental conditions. The firing process also allows for the development of vibrant colors and textures, allowing manufacturers to cater to various aesthetic trends in roofing.

After firing, the tiles undergo quality control inspections. This stage ensures that only tiles meeting strict quality standards are packaged and shipped. Automated systems utilize advanced imaging technologies to detect defects, providing an efficient means of maintaining high product quality.

Finally, the tiles are packaged for distribution. Innovative packaging solutions help protect the tiles during transportation while also making handling easier for retailers and contractors.

In conclusion, the roof tile production line is a sophisticated amalgamation of technology and craftsmanship. By ensuring high-quality raw materials, efficient molding and drying processes, and rigorous quality control, manufacturers can deliver roof tiles that meet modern architectural demands. As the construction industry continues to evolve, investment in state-of-the-art production lines will be crucial for maintaining competitive advantage and meeting consumer expectations.