The burgeoning demand for roller shutter doors across various industries—ranging from retail to industrial warehouses—has spurred interest in the machinery that manufactures these essential security features. A roller shutter door making machine serves as a cornerstone for businesses aiming at customizing security solutions. With an intricate blend of engineering prowess and technological innovation, these machines have transformed the way roller shutter doors are produced, expediting production times and enhancing product quality like never before.

At the heart of every roller shutter door making machine lies an expertly calibrated assembly line designed for precision and efficiency. These machines are an epitome of engineering expertise, equipped to handle the complex processes of cutting, rolling, assembling, and coding. The process begins with high-quality steel or aluminum coils, which are meticulously cut into specific shapes and sizes. This initial phase demands an expert understanding of materials science—knowing how different metals react under stress, temperature, and various environmental conditions. A miscalculation here can lead to product failures that could compromise building security.

The production process is further refined with computerized numerical control (CNC) systems, which ensure accuracy down to the millimeter. Such precision is indispensable, especially when the roller shutter doors are designed for high-security areas requiring a seamless fit and impenetrability. Expertise in computer programming and mechanical engineering guides the integration of these CNC systems into roller shutter door making machines, making them both agile and robust.

An authoritative characteristic of modern roller shutter door making machines is their ability to produce customized designs.

While standard models exist, the demand for bespoke solutions is on the rise. Authoritativeness in this realm comes from hands-on experience and an in-depth understanding of market demands. Companies that excel are those with seasoned professionals who have witnessed technological advancements over decades, who understand the nuances of aesthetic design versus functional security.

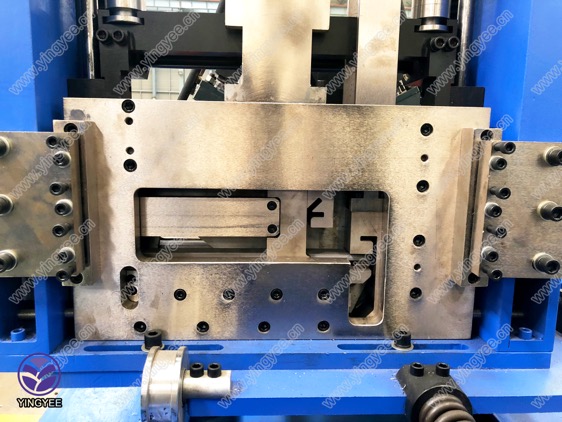

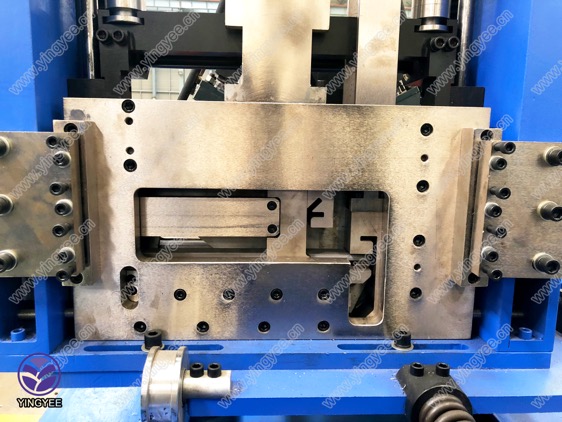

roller shutter door making machine

Moreover, trustworthiness is tightly linked to the quality controls embedded within the machinery. A roller shutter door making machine worth its salt incorporates multiple layers of quality checks. From laser sensors that detect discrepancies to software that logs operational data for future enhancements, these machines stand as paragons of reliability. The trust is built over years of consistent performance, minimized downtime, and the ability to adapt to legislative changes across different regions concerning construction and security norms.

A truly innovative roller shutter door making machine doesn’t just churn out doors; it adds value through a user-friendly interface, steering clear of cumbersome, outdated systems. A seamless operation is the result of an intuitive control panel which reduces the learning curve for operators, thereby maximizing productivity. Training modules often accompany these state-of-the-art machines, reflecting an educational commitment to ensuring users have the requisite expertise. Knowledge transfers and hands-on demonstrations often underline the difference between successful implementation and user error.

Even the post-sale service has evolved, backed by guarantees and service contracts that extend the machine’s lifecycle while promising support when adjustments or repairs are necessary. Manufacturers of these machines stand as industry authorities, often setting benchmarks for safety, efficacy, and innovation in production techniques.

In summary, a roller shutter door making machine is more than just a piece of industrial equipment; it is a marvel of modern engineering that encapsulates experience, expertise, authoritativeness, and trustworthiness. It creates a harmonious balance between ancient artisanal practices and cutting-edge technology, ensuring businesses not only meet their current needs but are poised to adapt to future challenges. With the continuous evolution of materials and technological possibilities, these machines signify a promising future where security and design harmoniously converge.