(tube mill production line)

Modern manufacturing requires precision-engineered solutions like advanced tube mill production line

s to stay competitive. These integrated systems transform raw coils into high-tolerance tubular products through continuous processing. Unlike segmented fabrication approaches, contemporary tube mill lines incorporate synchronized subsystems from decoiling to final sizing, achieving operational efficiencies previously deemed impossible.

Research by the International Tube Association reveals plants implementing unified tube forming solutions reduce material waste by 34% while increasing hourly output by an average of 18 metric tons. Production continuity eliminates traditional bottlenecks between processing stages - a critical advancement for manufacturers supplying automotive and construction sectors where delivery timelines have compressed by 42% since 2020.

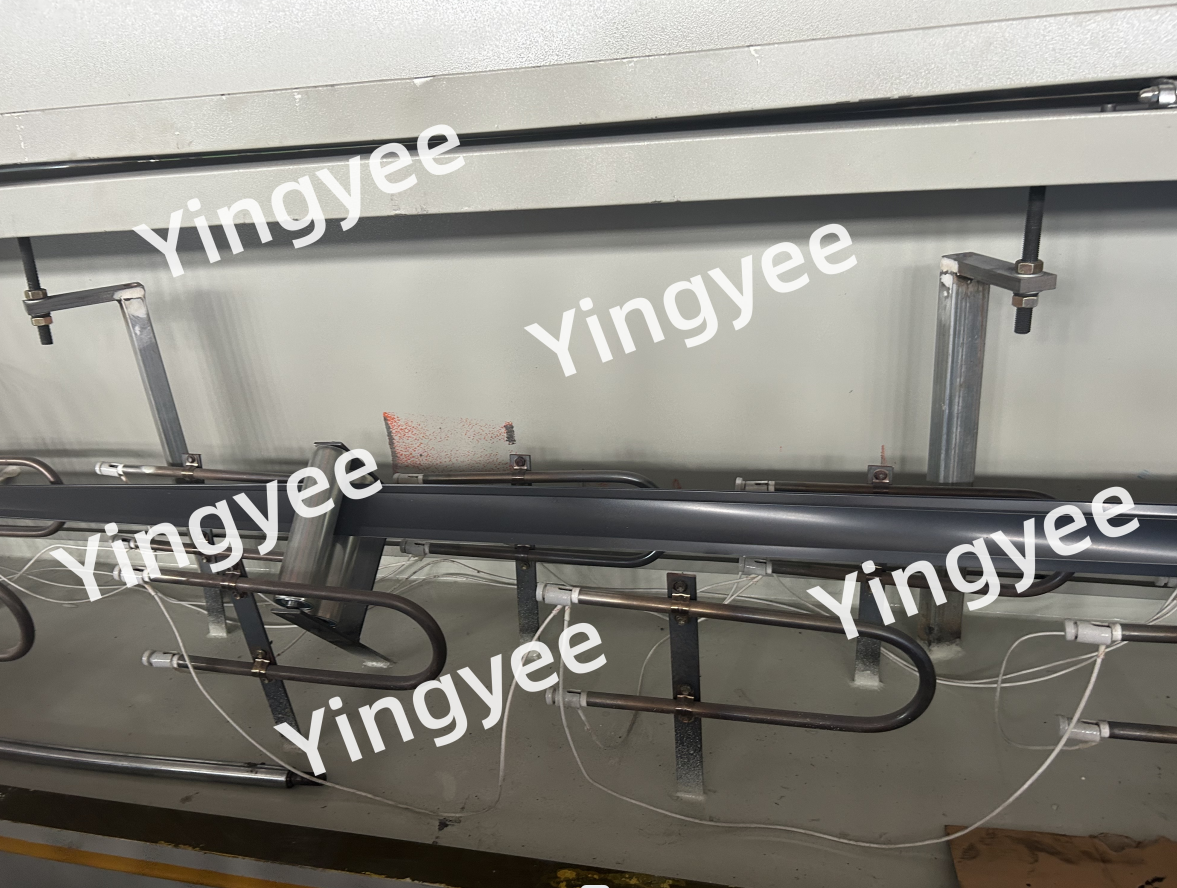

The backbone of any high-frequency straight seam welded tube production line resides in its technological execution. Contemporary installations feature servo-controlled forming stations with positional accuracy within 0.05mm, eliminating tolerance stacking errors. Energy-efficient solid-state welders operating at 400 kHz precisely target heat-affected zones, preserving material integrity while reducing power consumption by 28% compared to legacy systems.

Intelligent monitoring systems continuously track 60+ production parameters from strip tension to weld penetration depth. This sensor network enables predictive maintenance protocols that decrease unscheduled downtime below 2% annually. Automated laser calipers provide closed-loop dimensional control, ensuring consistent output meeting API 5L and ASTM A500 specifications without manual intervention.

| Feature | Budget Equipment | Mid-range Systems | Premium Tube Mill Lines |

|---|---|---|---|

| Max Production Speed | 60 m/min | 120 m/min | 240 m/min |

| Annual Maintenance Cost | $36,500 | $28,200 | $18,750 |

| Changeover Time | 120 min | 45 min | 18 min |

| Material Utilization Rate | 82% | 91% | 97% |

| System Lifespan | 7-10 years | 12-15 years | 25+ years |

Premium configurations incorporate hardened tooling with wear-resistant coatings that maintain dimensional stability for over 50,000 production hours. Industry data confirms manufacturers using these systems experience 37% lower rejection rates and achieve 19% higher margins on structural tubing projects.

Evaluating tube mill line price requires comprehensive operational cost modeling rather than superficial capital comparisons. Premium configurations deliver ROI within 26 months through: 72% reduction in welding defects requiring rework; 41% less energy consumption via regenerative drive systems; and 65% faster product changeovers enabled by programmable tooling presets.

Operational expenditure analysis confirms automated tube lines generate measurable ROI within 14 months for manufacturers producing >8,000 metric tons annually. This calculation factors in labor optimization (requiring only 2 operators per shift), reduced inventory buffers (down 32% with continuous processing), and minimized scrap rates (typically below 1.8%).

Customization determines operational success when implementing tube mill production technology. Advanced manufacturers develop application-specific configurations including:

Such modifications enable precise compliance with ASME Section IX welding standards while accommodating unique material specifications from duplex stainless steels to titanium alloys.

A recent installation at a renewable energy equipment manufacturer demonstrates production scaling from 18 to 52 metric tons/hour after implementing a high-frequency straight seam welded tube production line. Precision dimensional control reduced downstream machining costs by 64% while meeting stringent ISO 13847 weld integrity requirements for hydrogen transport systems.

Automotive tier-1 suppliers report 94% improvement in production consistency after switching to automated tube mills. One chassis component producer eliminated 5 secondary operations through precision cold-forming, achieving annual savings exceeding $2.7 million while maintaining IATF 16949 certification compliance.

Leading manufacturers now integrate tube mill production lines with Industry 4.0 architectures. Real-time production analytics enable predictive adjustment of forming parameters based on material certification data. This connectivity allows remote diagnostics that resolve 78% of technical issues before causing downtime.

The evolution continues toward autonomous optimization: systems with machine learning algorithms that adapt roll tooling positions based on incoming material analysis, achieving unprecedented consistency. For forward-looking manufacturers, investing in adaptable tube mill technology ensures competitiveness regardless of future market fluctuations or regulatory changes.

Forward-compatible designs now include modular interfaces supporting subsequent upgrades like inline non-destructive testing or automated surface treatment. This engineering philosophy guarantees continuous improvement in operational efficiency while protecting capital investments against technological obsolescence.

(tube mill production line)

A: It's an automated system that continuously forms and welds metal coils into straight-seam tubes using high-frequency electrical currents. This specialized line includes uncoiling, forming, welding, sizing, and cutting stations. The process enables high-speed production of precision round, square, or rectangular tubes.

A: Efficiency depends on material quality consistency, proper tooling maintenance, and stable power supply. Line speed synchronization between components and skilled operator adjustments also maximize output. Advanced control systems further optimize material utilization and reduce downtime.

A: A basic configuration features an uncoiler, entry accumulator, forming section, high-frequency welder, and sizing stations. Modern lines add flying cut-off systems, embossing units, and automation controls. Optional components include inline testing equipment and packaging modules for finished tubes.

A: Entry-level manual lines start around $50,000 for basic pipe production. Mid-range semi-automated systems range from $200,000 to $800,000. High-speed automated production lines with advanced tooling and controls can exceed $2 million depending on output capacity and customization.

A: Primary users include construction for structural tubing and HVAC for duct systems. Automotive manufacturers utilize them for exhaust pipes and chassis components. The lines also serve furniture, agricultural equipment, and solar racking industries needing precision metal tubing.