Understanding Square and Round Downspout Roll Forming Machines

In the world of modern construction and roofing, efficient drainage systems are essential for maintaining structural integrity and preventing water damage. One of the key components of these systems is the downspout, which channels rainwater from gutters away from the building foundation. To meet the increasing demand for durable and aesthetically pleasing downspouts, manufacturers turn to specialized machinery, particularly square and round downspout roll forming machines.

What is a Roll Forming Machine?

A roll forming machine is a type of machinery used to produce long lengths of metal profiles by feeding a continuous strip of metal through a series of rollers. These rollers shape the metal into desired profiles - in this case, downspouts. Roll forming is known for its efficiency, allowing for high production rates and minimal material waste. When it comes to downspouts, manufacturers can choose whether they want square or round designs, both of which serve their purpose effectively.

Square Downspouts

Square downspouts have gained popularity due to their modern appearance and ease of installation. The production of square downspouts involves a roll forming machine specifically designed to create angular profiles. These machines can produce downspouts in various sizes and gauges, accommodating different building specifications and aesthetic preferences.

The advantages of using square downspouts include their compatibility with many architectural styles and their ease of integration into existing gutter systems. Moreover, they can efficiently direct water flow, preventing overflow and facing drainage issues. Square downspouts can also be manufactured using various materials such as aluminum, galvanized steel, and copper, enhancing their durability and aesthetic appeal.

Round Downspouts

Round downspouts, although less popular than square downspouts in some regions, offer unique advantages that make them valuable in specific applications. They have a more traditional appearance and are often preferred for historical buildings or architectural styles that emphasize curves and softer lines. Roll forming machines configured for round downspouts can produce numerous sizes, giving designers flexibility in their projects.

The round shape of these downspouts facilitates smooth water flow, reducing the likelihood of clogs. Additionally, they can withstand higher water pressure, making them suitable for areas with heavy rainfall. Round downspouts can also be designed with decorative elements, allowing them to blend in seamlessly with the building’s exterior while providing vital drainage solutions.

The Roll Forming Process

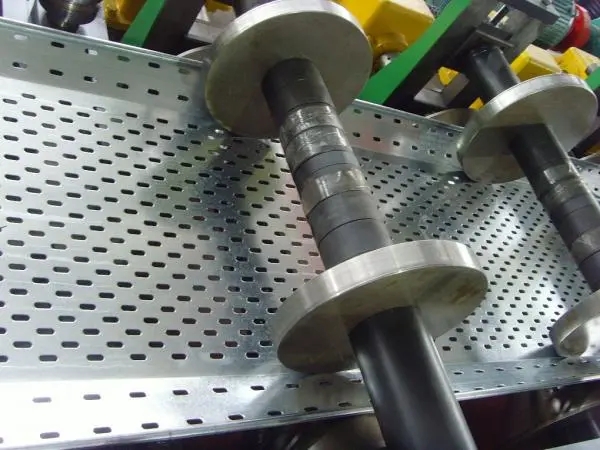

The roll forming process for both square and round downspouts typically begins with unwinding a metal coil and feeding it into the roll forming machine. As the metal travels through various sets of rollers, it progressively takes on the desired shape. Once the downspout profile is formed, it is cut to length according to specifications.

Advanced machines come equipped with features like automatic adjustments for thickness and width, ensuring that the production process is both efficient and accurate. Additionally, quality control measures are integrated throughout the roll forming process to ensure that the dimensions, surface quality, and overall durability of the downspouts meet industry standards.

Conclusion

Square and round downspout roll forming machines play a vital role in the construction industry, providing efficient and cost-effective solutions for rainwater drainage systems. With their ability to produce customized profiles quickly, these machines meet the growing demands for both functionality and aesthetics. Whether for residential, commercial, or industrial applications, the right downspout can contribute to the longevity of a building while enhancing its visual appeal. As technology continues to advance, we can expect even more innovations in downspout manufacturing, benefiting both builders and property owners alike.

Investing in quality downspout roll forming machinery not only increases production efficiency but also represents a commitment to delivering high-quality products that protect buildings from water damage over the long term.