Vertical Large Span Roll Forming Machine An Overview

In the realm of modern manufacturing, the demand for efficient and high-capacity production machinery continues to grow. Among these innovations, the vertical large span roll forming machine has emerged as a noteworthy solution, widely recognized for its ability to produce high-quality profiles with significant structural integrity and minimal material wastage. This article explores the operational principles, advantages, and applications of vertical large span roll forming machines, underscoring their importance in contemporary industrial processes.

Understanding Roll Forming Technology

Roll forming is a manufacturing process that produces long metal parts with constant cross-sections. The process utilizes a series of rolls to progressively bend a flat metal strip into the desired shape. This technology is highly efficient, as it allows for the continuous production of complex profiles with high precision. Amid the several configurations of roll forming machines, vertical systems are uniquely designed to accommodate larger spans, making them particularly valuable in sectors that require robust structural components.

Design and Functionality of Vertical Large Span Roll Forming Machines

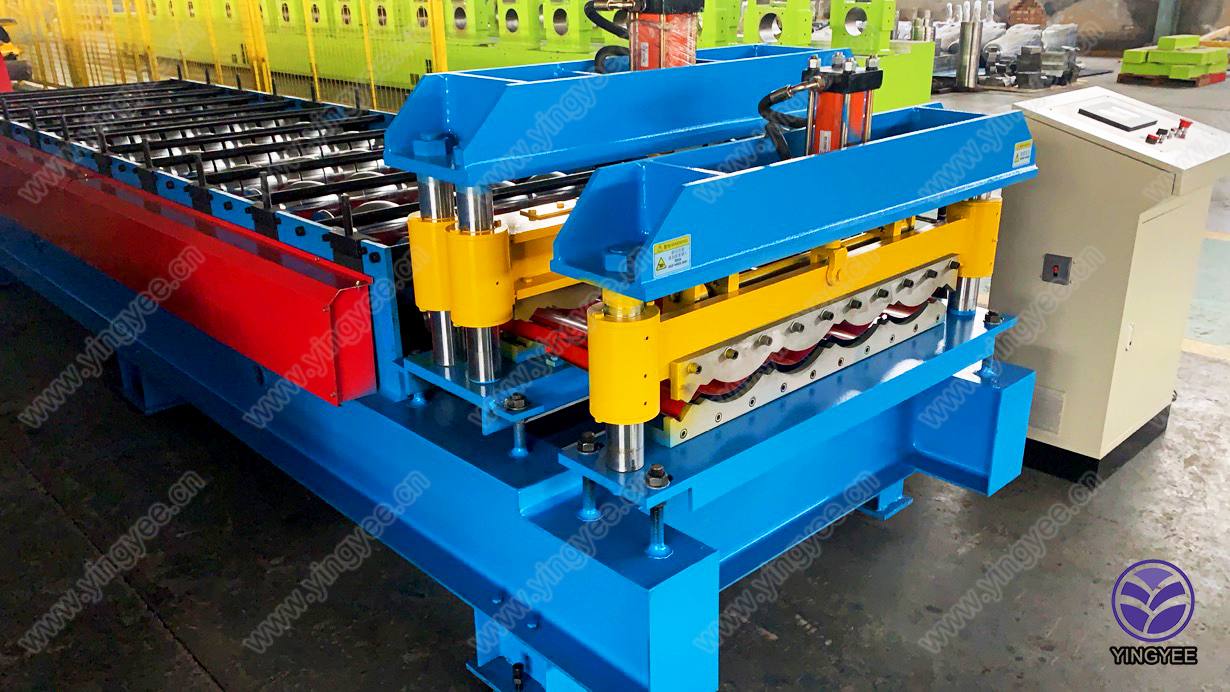

Vertical large span roll forming machines have a distinctive vertical configuration that sets them apart from traditional horizontal models. This design enables the handling of larger and heavier materials, which is essential for producing components in construction, automotive, and aerospace industries. The vertical arrangement allows gravity to aid in the metal feeding process, enhancing operational efficiency and reducing the risk of material deformation.

Moreover, these machines typically consist of multiple forming stations, where each station introduces specific bends or shapes to the strip metal. The key to their efficiency lies in their ability to perform this transformation with precision while maintaining high throughput rates. Advanced hydraulic or electric systems are often integrated into these machines to ensure reliable operation and to facilitate rapid changes in profiles.

Advantages of Vertical Large Span Roll Forming Machines

2. Increased Production Capacity These machines can operate at high speeds, allowing manufacturers to meet large orders efficiently. The combination of continuous production and rapid setup times translates into lower operational costs.

3. Material Conservation Roll forming minimizes waste by utilizing materials more effectively than traditional cutting and shaping processes. The precision of the machine ensures that the maximum length of usable profile is achieved from the raw material.

4. Versatility Vertical large span roll forming machines are capable of producing a wide range of profiles, from simple shapes to complex designs. This adaptability makes them invaluable in various industries.

5. Enhanced Profile Strength With the ability to manipulate thicker sheets and larger spans, these machines produce profiles that exhibit greater strength and durability, meeting the stringent requirements of structural applications.

Applications in Various Industries

The applications of vertical large span roll forming machines are extensive. In the construction sector, they are utilized to manufacture structural components such as steel frames, beams, and roofing panels. The automotive industry benefits from these machines by using them to produce parts such as chassis components and body panels. Moreover, the aerospace sector employs roll-formed parts for their lightweight yet strong characteristics, essential for fuel efficiency and performance.

Conclusion

The vertical large span roll forming machine represents a significant advancement in manufacturing technology, catering to the increasing demand for large, durable, and precise profiles in various industries. The combination of efficiency, versatility, and material savings makes these machines a critical asset for manufacturers looking to enhance productivity while maintaining quality standards. As technological innovations continue to evolve, the role of vertical large span roll forming machines will undoubtedly expand, shaping the future of production processes across multiple sectors.