For businesses involved in construction and renovation, optimizing operations remains a fundamental objective. An essential component of this optimization involves utilizing advanced equipment, such as the stud and track/drywall/wall angle production line. This machinery significantly enhances the efficiency and quality of construction projects. Leveraging genuine experience, expertise, authoritativeness, and trustworthiness, this article delves into the core facets of a sophisticated stud and track production line.

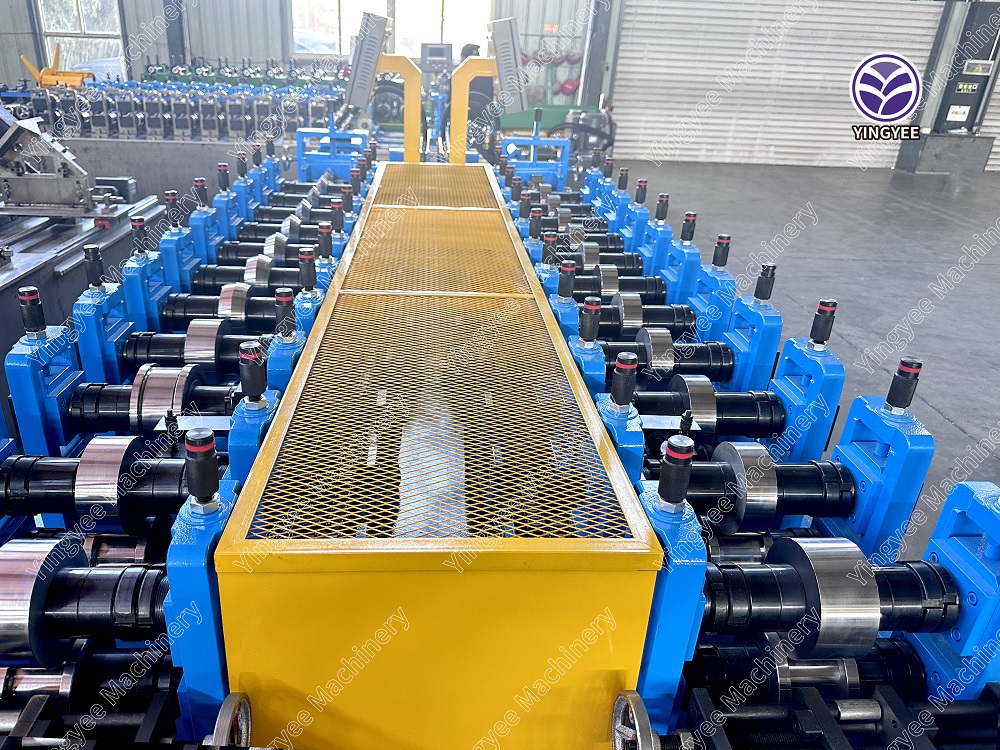

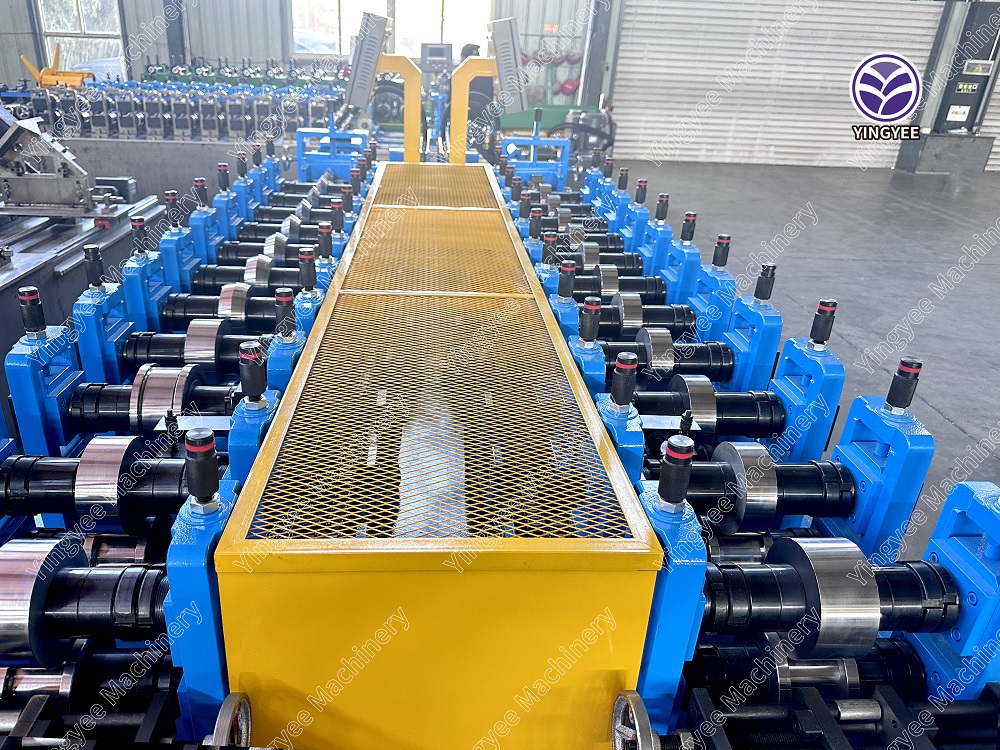

The stud and track production line embodies decades of engineering advancement and industry-specific expertise. Its sophistication begins with an ingeniously designed feeding system. By incorporating a high-precision uncoiling process, the line guarantees supply consistency, which is paramount for maintaining uniform product quality. This meticulous attention to detail distinguishes superior production lines from their less advanced counterparts.

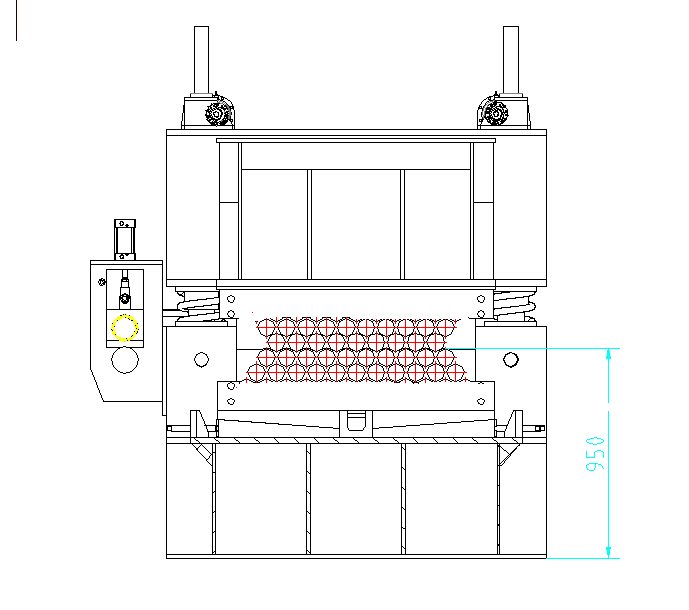

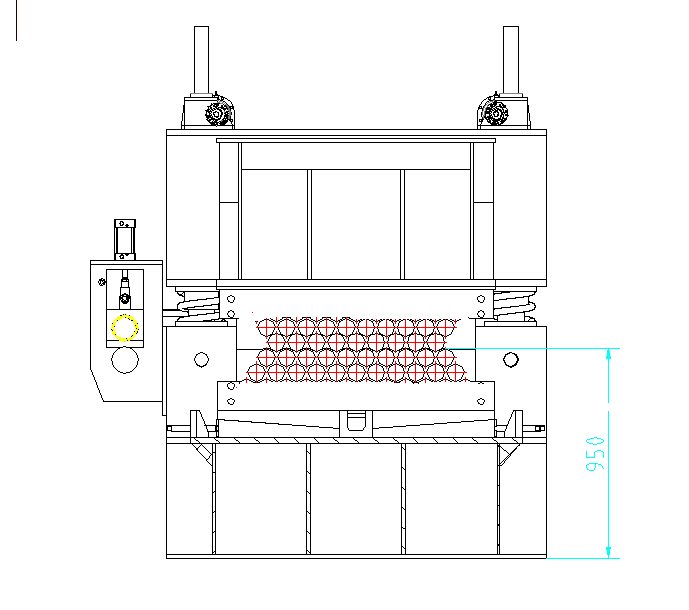

Equipped with CNC technology, the roll-forming system of a production line is another testament to its expertise and authority in metal shaping. Computer Numerical Control (CNC) ensures unparalleled precision, allowing manufacturers to produce studs, tracks, and wall angles with exact specifications rapidly. The accuracy maintained by CNC technology minimizes material wastage, which aligns with contemporary needs for sustainable production methods.

The integration of cutting-edge software enhances a production line's flexibility, further emphasizing its expert design. The software allows operators to swiftly alter product dimensions, profiles, and configurations with minimal downtime. This feature is particularly beneficial in meeting diverse client needs without necessitating extensive equipment overhauls. Customization and agility become standard offerings, strengthening a company's reputation for professionalism and reliability.

Authoritative knowledge of material science reinforces the efficacy of modern stud and track production lines. Manufacturers utilize metals—often galvanized steel—chosen for their durability and resilience to environmental factors such as corrosion. Understanding these materials ensures that finished products can withstand prolonged stress without compromising structural integrity.

stud and track/ drywall/wall angel production line

Quality control, embedded within the production process, underscores the operational trustworthiness of these lines. Advanced sensors and automated inspection systems constantly monitor output for defects or inconsistencies, preserving high standards of quality. This assurance is crucial, especially in structural applications where safety and longevity are non-negotiable.

Real-world experience further validates the appeal of an exemplary stud and track production line. Businesses that integrate these systems report increased productivity and a noteworthy reduction in labor costs due to automation. In practice, these lines shorten project timelines while enhancing output accuracy and operator safety. Such first-hand accounts affirm the overarching value of investing in high-quality production technology.

Trust is another facet reinforced by prominent manufacturers' adherence to international production standards and certifications. By aligning with organizations that set rigorous quality benchmarks, manufacturers provide clients with an assurance of compliance and reliability. This adherence not only builds confidence but also elevates the manufacturer's standing as a preferred partner in construction ventures.

In summary,

stud and track/drywall/wall angle production lines epitomize technological excellence and precision for construction applications. They merge advanced automation with authoritative expertise in material science, ensuring high-quality output and operational efficiency. Relying on these lines bolsters a business’s capability to deliver consistent, reliable results, enhancing client trust and satisfaction. Whether assessed through the lens of experience, expertise, authority, or trustworthiness, such production lines remain indispensable assets in the modern construction landscape.