Square and round downspout roll forming machines represent a pivotal advancement in the production of durable, efficient gutter systems. These specialty machines are engineered to create seamless downspouts tailored to various architectural requirements, enhancing their aesthetic and functional contributions to residential and commercial buildings.

At the intersection of technology and material science, square and round downspout roll forming machines offer unparalleled precision. Each unit is designed to handle pre-processed metal sheets, transforming them into finely detailed downspouts through a series of systematic roll forming stages. This transformation process is not only precise but also remarkably efficient, providing high-volume output with minimal material wastage.

Square downspouts are particularly favored in contemporary designs, providing a crisp, modern look that complements geometric architectural styles. The machinery designed for these square configurations must accommodate sharp bends and smooth transition points, ensuring that the final product is both functional and visually pleasing. Machines that produce square downspouts are often equipped with advanced programmable logic controllers (PLCs) and automated feeding systems, enhancing the precision and consistency of each output.

Conversely, round downspouts cater to a more traditional aesthetic, seamlessly blending with a wide range of building facades. The engineering challenges associated with round downspout machines focus on achieving perfect cylindrical shapes that maintain structural integrity over extended lengths. The intricacies involved in producing round downspouts lie in fine-tuning the roller dies to ensure smooth, even curves.

Expertise in operating these machines is not only about understanding the mechanics but also involves an awareness of the materials being used. Aluminum and galvanized steel are the most common materials, chosen for their durability and resistance to environmental elements. Operators must ensure that the material's thickness aligns with the machine design specifications to prevent wear and tear on the equipment.

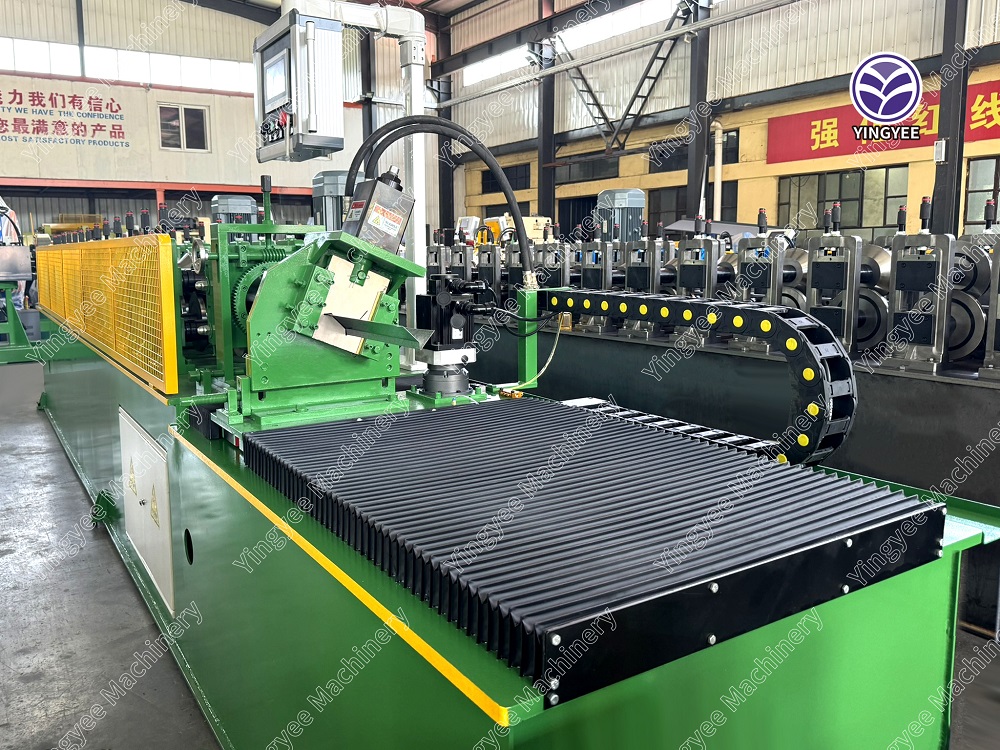

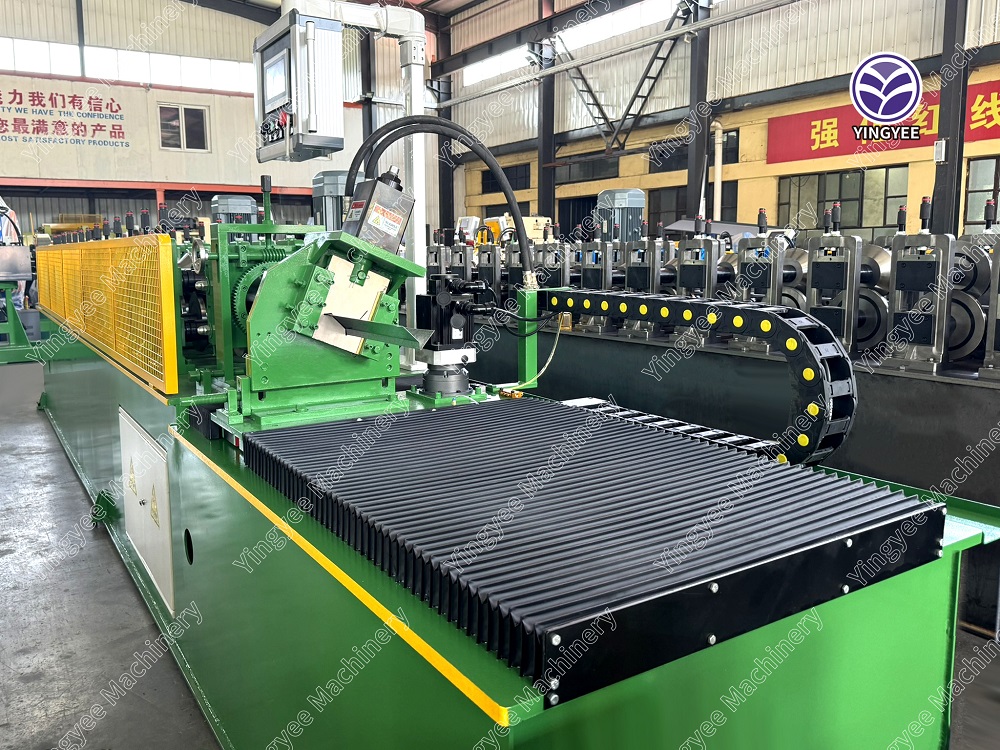

square/round downspout roll forming machine

Authoritativeness in the field of downspout roll forming technology is often validated by certifications and affiliations with industry standards. Manufacturers and operators seek compliance with international quality benchmarks, ensuring that the products meet stringent safety and durability standards. Leading-edge manufacturers regularly participate in global exhibitions, share research findings, and engage in collaborative projects to push the boundaries of what these machines can achieve.

Building trust through reliability and customer service is paramount in the roll forming industry. Companies that stand out invest heavily in after-sales support, offering maintenance, upgrades, and training to ensure that clients can maximize their investment in these machines. Detailed service agreements and readily available technical support teams are indicative of a company's commitment to long-term client satisfaction.

Incorporating the latest technological advancements, some manufacturers are integrating IoT capabilities into their roll forming machines. This feature allows for real-time monitoring and diagnostics, thus reducing downtime and enhancing productivity. By leveraging data analytics, operators can make informed decisions on machine settings and maintenance schedules, ensuring optimal performance.

Investing in a square or round downspout roll forming machine requires a thorough understanding of both current capabilities and future potential. As buildings increasingly move towards sustainable and energy-efficient designs, the demand for high-quality, customizable downspouts is set to rise. Visionary manufacturers are therefore focusing on the eco-friendliness of their production processes, utilizing recyclable materials, and reducing carbon footprints through energy-efficient operations.

In conclusion,

square and round downspout roll forming machines are integral to modern architectural design and construction. With their precision engineering, material versatility, and adaptability to various design needs, these machines offer extensive possibilities for the future of building exteriors. As technology continues to evolve, the role of downspout roll forming machines will likely expand, driving innovation, efficiency, and an ever-greater harmony between functionality and design in gutter systems worldwide.