Understanding PU Sandwich Panel Machines Revolutionizing Construction

In recent years, the construction industry has seen a significant transformation with the advent of innovative technologies and machinery. One such game-changing technology is the PU (Polyurethane) sandwich panel machine, which has revolutionized the way builders approach insulated structures. This article will explore what PU sandwich panels are, the working mechanism of the machines that produce them, and the advantages they bring to construction.

What are PU Sandwich Panels?

PU sandwich panels consist of three layers a core made of polyurethane foam sandwiched between two outer layers, typically made from metal sheets like steel or aluminum. The polyurethane core provides excellent thermal insulation, while the outer metal panels offer durability and structural integrity. These panels are available in various thicknesses and can be customized to meet specific building requirements. The combination of materials ensures that the panels are lightweight yet robust, making them ideal for various applications including warehouses, cold storage facilities, and even residential buildings.

The Working Mechanism of PU Sandwich Panel Machines

The production of PU sandwich panels requires a specialized machine that combines different elements to form the final product. A PU sandwich panel machine typically features several key components

1. Foam Injecting System This system is responsible for injecting liquid polyurethane foam into the panel's core. The foam expands and solidifies, providing insulation once cured.

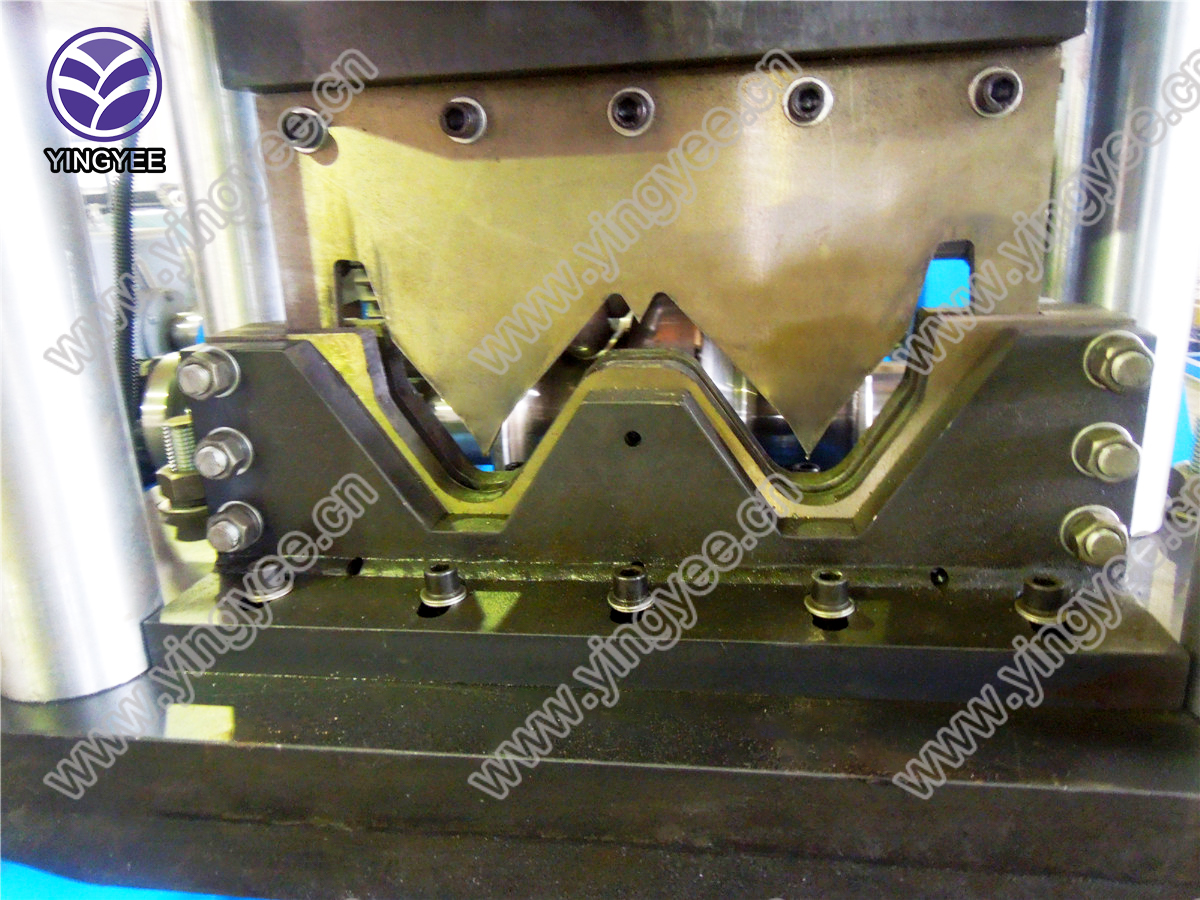

2. Roll Forming Unit This unit shapes the outer metal sheets into the desired profile. Roll forming is a continuous bending operation where sheet metal is passed through sets of rolls to achieve a specific cross-section.

3. Pressing Unit After the foam is injected, the pressing unit ensures that the outer metal sheets adhere properly to the foam core. This is crucial for achieving the desired strength and insulation properties.

4. Cutting System Once the panels are formed and pressed, they need to be cut to specific lengths. The cutting system uses precision tools to ensure clean and accurate cuts.

5. Control System A sophisticated control system monitors and regulates the entire production process, ensuring quality and efficiency. Modern machines often utilize PLC (Programmable Logic Controller) for real-time monitoring and adjustments.

Advantages of PU Sandwich Panel Machines

The benefits of using PU sandwich panels in construction are numerous

1. Energy Efficiency One of the standout features of PU sandwich panels is their excellent thermal insulation properties, which can significantly reduce heating and cooling costs in buildings. This energy efficiency is increasingly important as global energy demands rise and environmental concerns increase.

2. Speed of Construction PU sandwich panels are quick and easy to install, allowing construction projects to move forward rapidly. The prefabricated nature of the panels reduces on-site labor time and minimizes waste.

3. Durability and Maintenance The materials used in PU sandwich panels are resistant to weathering, corrosion, and impact. This durability minimizes the need for maintenance and repairs over the lifespan of the building.

4. Versatility The applications of PU sandwich panels are vast. They can be used in industrial buildings, commercial facilities, and residential projects, making them a versatile choice for builders.

5. Cost-Effectiveness Although the initial investment in PU sandwich panel machines may be significant, the long-term savings in energy costs, labor, and maintenance make them a cost-effective option for many construction projects.

6. Eco-Friendly Solution As the construction industry increasingly shifts towards sustainable practices, PU sandwich panels present an eco-friendly solution. Their energy efficiency contributes to lower carbon footprints, and many manufacturers adhere to environmentally friendly production processes.

Conclusion

In summary, PU sandwich panel machines are paving the way for more efficient and sustainable construction practices. Their ability to produce high-quality insulated panels that are both durable and energy-efficient positions them as an essential tool in modern construction. As technology continues to advance, the capabilities and applications of PU sandwich panels will likely expand, further enhancing their role in building the structures of the future.