Light Steel Keel Roll Forming Machine Revolutionizing Construction and Design

In the realm of modern construction and architectural design, the demand for efficient, durable, and lightweight materials has never been higher. One such innovation that has gained significant traction is the light steel keel roll forming machine. This advanced machinery plays a pivotal role in producing light steel keels, which are essential components in numerous construction applications, particularly in the realm of drywall systems, ceilings, and partitions.

Understanding Light Steel Keels

Light steel keels are structural supports made from cold-formed steel, characterized by their light weight and high strength-to-weight ratio. They are primarily used in drywall systems due to their ability to provide support without adding excessive weight to structures. Their lightweight nature makes installation easier and faster, reducing labor costs and improving overall project timelines. The ability to withstand high loads while maintaining structural integrity is what makes them a preferred choice among builders and architects alike.

The Role of Roll Forming Machines

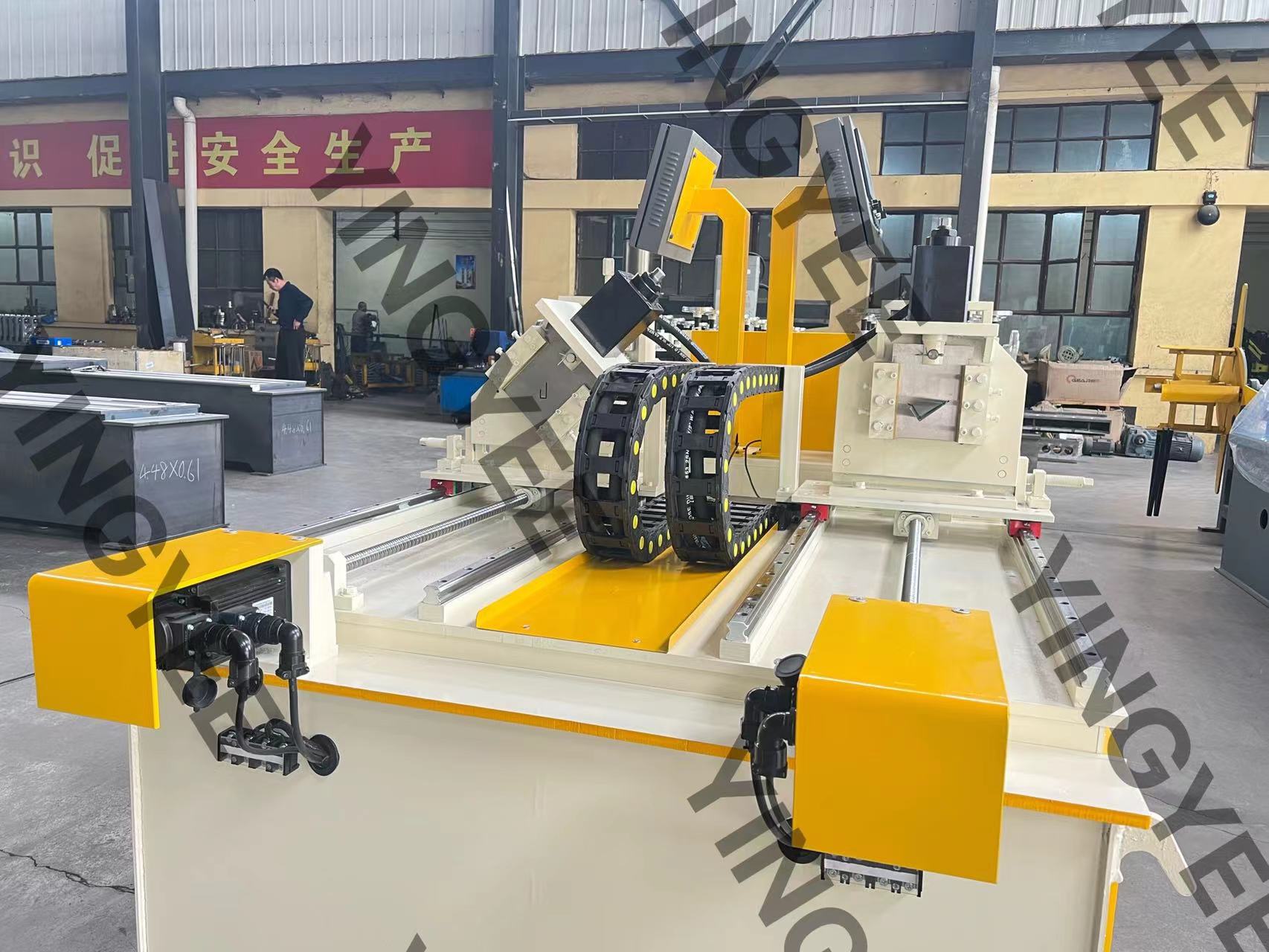

A roll forming machine is an essential tool in the manufacturing process of light steel keels. The machine operates by feeding flat steel strips through a series of rollers that progressively shape the material into the desired profile. This continuous process allows for mass production of kerbs with consistent quality, thickness, and precision. The resulting products are not only uniform in shape but also exhibit the necessary strength required for various applications in construction.

The light steel keel roll forming machine offers several advantages over traditional manufacturing methods. Firstly, it significantly reduces waste, as the process utilizes the entire width of the steel strip, allowing for minimal scraps. Secondly, the consistency and speed of production enhance efficiency, resulting in short lead times and a quick turnaround for construction projects.

Key Features of Light Steel Keel Roll Forming Machines

1. Versatility Modern light steel keel roll forming machines are designed to produce various profiles and sizes of steel keels, allowing manufacturers to cater to diverse client needs.

2. Automated Control Many machines are equipped with advanced computerized systems that facilitate precise control over the forming process. This ensures that every piece produced meets stringent quality standards.

3. Durability and Low Maintenance Constructed from high-quality materials, these machines are built to withstand heavy usage and require minimal maintenance, leading to reduced downtime and operational costs.

4. Energy Efficiency Advanced roll forming machines are designed with energy efficiency in mind, often incorporating features that minimize energy consumption without compromising performance.

Applications in Construction

The light steel keel roll forming machine plays a crucial role in various construction applications, particularly in the production of

- Suspended Ceilings Light steel keels are widely used in suspended or drop ceilings, providing essential support while allowing easy access to electrical and plumbing systems above.

- Partition Walls In commercial and residential buildings, light steel keels are used to create partition walls, allowing for flexible space management and reconfiguration options.

- Roofing Systems Light steel keels can also be utilized in roofing systems, providing essential structural support and enhancing overall building stability.

Conclusion

The introduction of light steel keel roll forming machines represents a significant advancement in the construction industry, offering efficient, cost-effective, and sustainable solutions for modern building needs. As architects and builders continue to seek innovative materials and methods, the role of these machines will undoubtedly grow, paving the way for a more efficient and adaptable construction landscape. With their ability to deliver high-quality products swiftly and sustainably, light steel keel roll forming machines are set to be a cornerstone of future construction practices. As the industry evolves, embracing technology and innovation will be key to meeting the challenges ahead.