The Advancements in Large Span Forming Machines

In the realm of manufacturing and construction, the demand for efficiency and precision has never been higher. A key player in this evolution is the large span forming machine, a tool designed to create substantial structural components with remarkable accuracy. These machines are crucial in industries such as aerospace, automotive, and construction, where the need for large-scale fabrication is prevalent.

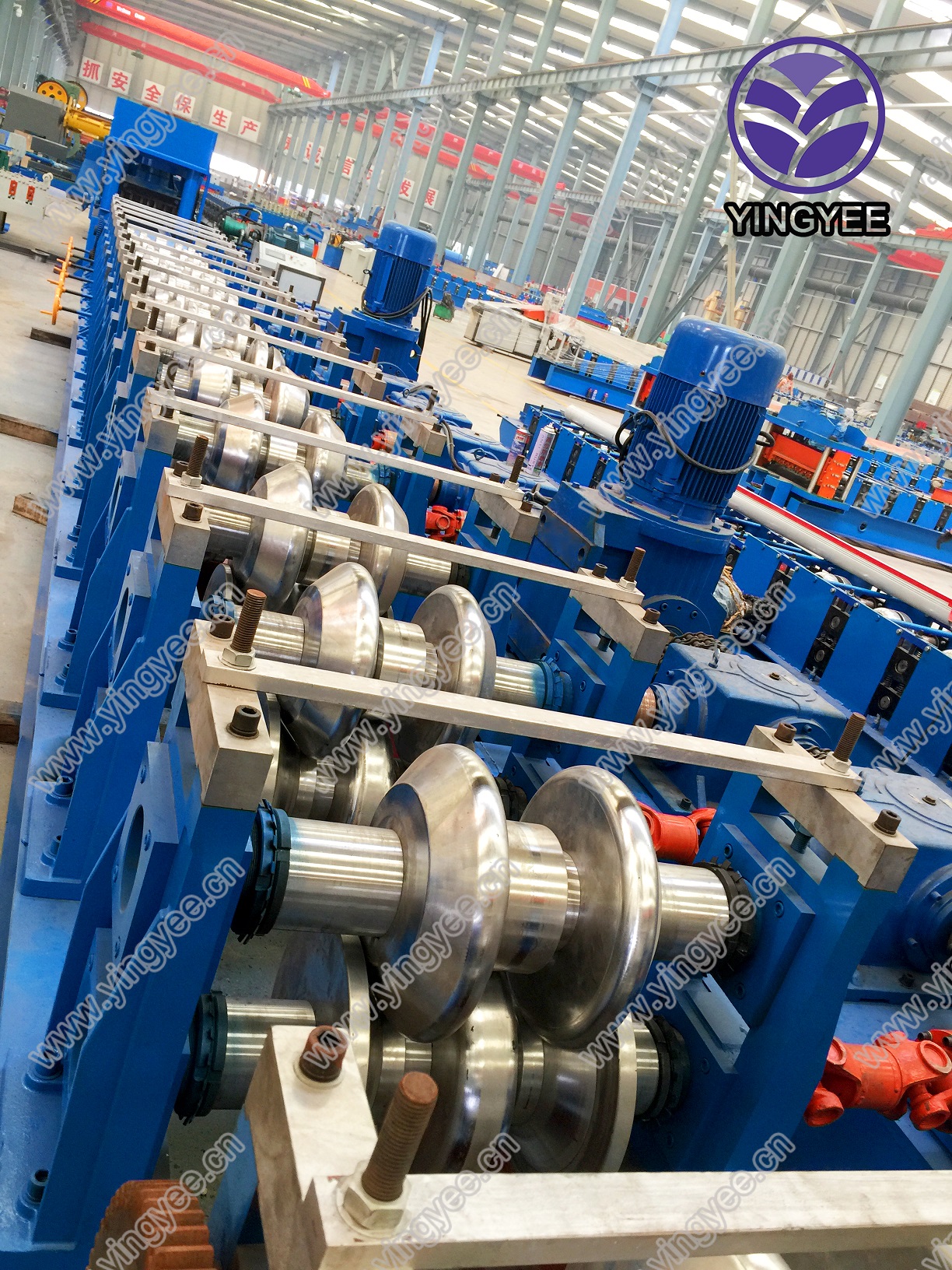

Large span forming machines are engineered to manipulate materials into complex shapes while maintaining structural integrity. They are capable of handling various materials, including metals, composites, and plastics, making them versatile for different applications. The technology behind these machines incorporates advanced computer numerical control (CNC) systems, which allow for intricate design and precise execution. This capability not only boosts productivity but also reduces waste, as materials are used more efficiently.

The importance of large span forming machines can be highlighted through their application in the construction industry. Building modern infrastructures such as bridges, stadiums, and large buildings requires components that can endure significant loads. These machines can fabricate large beams, trusses, and panels that meet stringent safety standards while also allowing for innovative architectural designs. As a result, architects and engineers can push the boundaries of conventional design, leading to more sustainable and aesthetically pleasing structures.

Furthermore, the automation involved in large span forming machines enhances safety and minimizes the risk of human error. Operators can program the machines to complete tasks autonomously, which not only speeds up the production process but also ensures a consistent quality of the outputs. Additionally, advancements in technology have led to the development of smart machines that can monitor their operations in real-time, providing feedback and making necessary adjustments during the manufacturing process.

Looking ahead, the future of large span forming machines appears promising. With ongoing research and development, innovations such as 3D printing and advanced robotics may soon be integrated into these machines, further revolutionizing the manufacturing landscape. This integration could lead to reduced production times and lower costs, making large span components more accessible for various projects.

In conclusion, large span forming machines represent a significant advancement in the manufacturing industry. Their ability to create large, complex structures with precision and efficiency not only meets the rising demands of modern construction but also opens up new possibilities for innovative design. As technology continues to evolve, these machines will undoubtedly play a crucial role in shaping the future of manufacturing and construction.