Understanding C Purlin Roll Forming Machines

In the construction and manufacturing sectors, efficiency and cost-effectiveness are paramount. C purlins play a vital role in structural applications, commonly utilized in the construction of buildings, warehouses, and other large structures. As the demand for purlins rises, the need for efficient production methods becomes increasingly important. This is where C purlin roll forming machines come into play.

What is a C Purlin?

Before delving into the machinery, it is essential to understand what C purlins are. C purlins are horizontal structural members used to support roofs and walls. They are fabricated from cold-formed steel, making them lightweight yet durable and capable of withstanding varying loads. The “C” shape of these purlins provides a high degree of strength and support, ideal for various construction applications.

The Role of C Purlin Roll Forming Machines

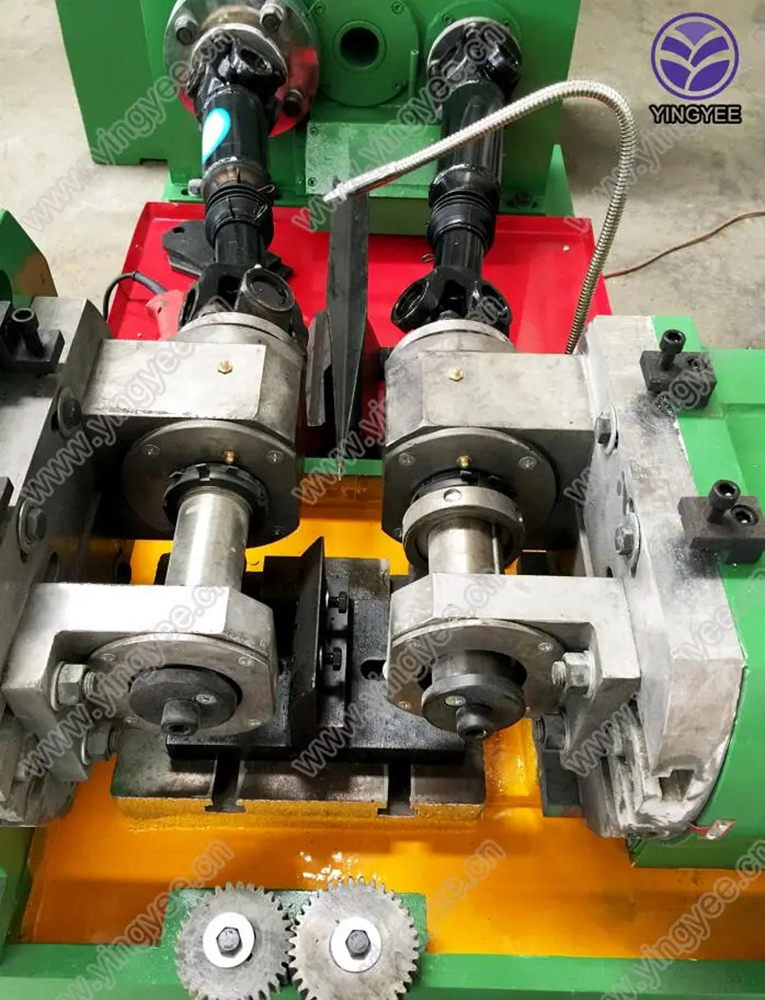

C purlin roll forming machines are specialized equipment designed to manufacture C purlins efficiently. These machines utilize a continuous roll forming process to convert flat steel sheets into C-shaped profiles. The roll forming process involves feeding the steel strip through a series of rollers that progressively shape it into the desired profile.

Key Features of C Purlin Roll Forming Machines

1. High Production Efficiency One of the most significant advantages of using a roll forming machine is its high production efficiency. These machines can produce large quantities of C purlins in a relatively short time, reducing labor costs and maximizing output.

2. Precision and Consistency C purlin roll forming machines are designed to provide precision in the production process. The consistent shape and dimensions of each purlin ensure that they meet industry standards and customer specifications.

3. Versatility Many roll forming machines are adaptable, allowing manufacturers to produce various sizes and thicknesses of C purlins. This versatility makes them suitable for different construction projects, from small buildings to large industrial structures.

4. Reduced Waste The roll forming process is highly efficient and generates minimal waste compared to traditional manufacturing methods. This not only lowers material costs but also benefits the environment through reduced scrap.

5. Automation Capabilities Advanced C purlin roll forming machines come equipped with automation features, including programmable controls and adjustments. Operators can easily set parameters for different production runs, enhancing efficiency and reducing downtime.

The Manufacturing Process

The manufacturing process of C purlins using a roll forming machine begins with the selection of raw material, typically cold-rolled or hot-rolled steel sheets. Once the steel is fed into the machine, it passes through a series of rollers that reshape it into the desired C profile.

As the metal progresses through the rollers, it may also undergo additional processes such as punching holes or cutting to length, depending on the specific requirements of the finished product. Once shaped, the purlins are typically cut to size, and any necessary finishing processes, such as coating or galvanizing, are applied for corrosion resistance.

Conclusion

The C purlin roll forming machine is an invaluable tool in the construction and manufacturing industries, providing an efficient, precise, and versatile solution for producing C purlins. With the growing need for quick and reliable construction materials, investing in advanced roll forming technology becomes increasingly essential for manufacturers aiming to stay competitive. By leveraging the advantages of C purlin roll forming machines—such as high production efficiency, automation, and reduced waste—companies can enhance their operational performance while meeting the evolving demands of the market. As innovations in roll forming technology continue to develop, the future looks promising for manufacturers of C purlins, contributing to the ever-evolving landscapes of architecture and construction.