The Evolution and Importance of Cable Tray Making Machines

In the ever-evolving landscape of electrical infrastructure, the demand for efficient and reliable cable management solutions continues to rise. Central to this development are cable tray making machines, essential tools that streamline the manufacturing process of cable trays. These trays are crucial in supporting electrical cables in a variety of settings, including industrial plants, commercial buildings, and residential complexes. This article will explore the purpose, benefits, and advancements in cable tray making machines.

Understanding Cable Trays

Cable trays are systems used to secure and route electrical cables and wires in a safe, organized manner. They provide an effective way to manage cable runs and protect cables from damage. By utilizing cable trays, facilities can reduce the risk of fire hazards, improve ventilation around the wires, and facilitate easier maintenance and upgrades. The versatility of cable trays accommodates various shapes and sizes, making them ideal for diverse applications.

The Role of Cable Tray Making Machines

Cable tray making machines are designed to produce these critical components efficiently. They automate several processes, including cutting, bending, and welding metal sheets into finished cable tray products. By employing highly specialized machinery, manufacturers can achieve consistent quality and precision in their trays, minimizing human error and production time.

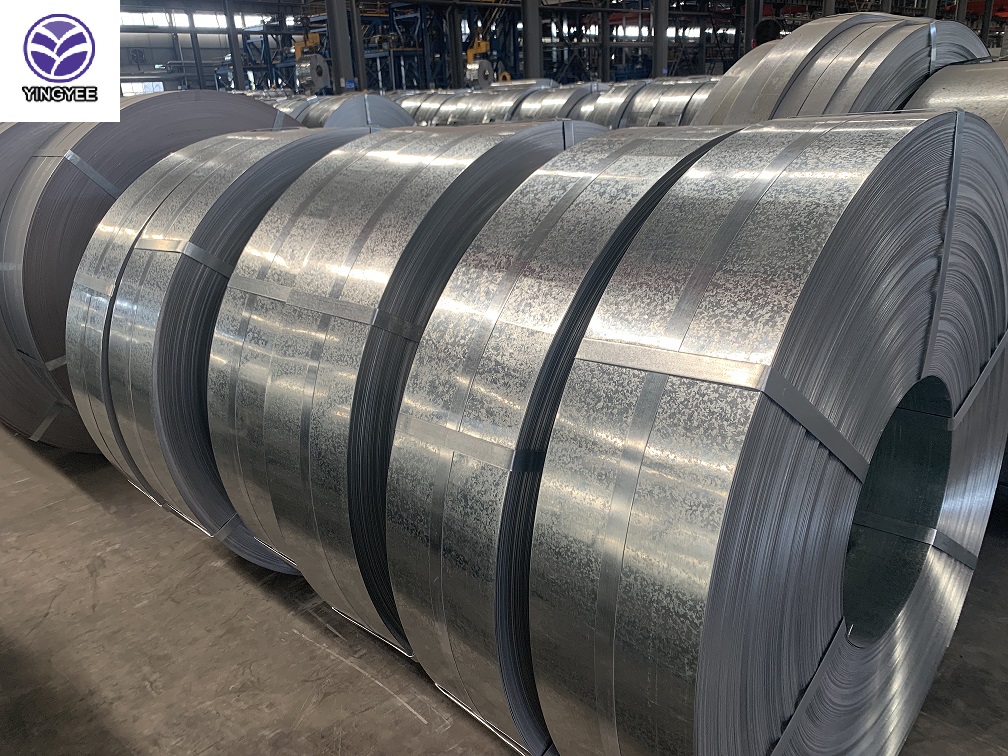

The typical cable tray making machine consists of several key components, including a decoiler, roll forming system, cutting unit, and bending equipment. These elements work in harmony to transform raw metal coils into ready-to-install cable trays. Advanced models are often integrated with computer numerical control (CNC) technology, enhancing accuracy and enabling complex designs to be executed seamlessly.

Advantages of Cable Tray Making Machines

1. Efficiency Traditional methods of producing cable trays are labor-intensive and time-consuming. Cable tray making machines dramatically speed up production processes, allowing manufacturers to meet increasing market demands without compromising quality.

2. Cost-Effectiveness By minimizing labor costs and reducing material waste, cable tray making machines contribute to lower overall production costs. The economies of scale achieved through automation make it feasible for manufacturers to offer competitive pricing.

3. Customization Modern cable tray making machines can produce trays in various shapes and sizes. This flexibility allows for tailored solutions to specific project requirements, such as variations in load capacity and installation environment.

4. Quality Assurance The automation and precision of cable tray making machines significantly enhance the quality of the finished products. With less manual intervention, the risks of defects and inconsistencies are reduced, leading to greater customer satisfaction.

Advancements in Technology

The field of cable tray making machinery has seen significant technological advancements in recent years. Innovations such as smart manufacturing and the integration of Industry 4.0 principles have transformed how these machines operate. Today, manufacturers can monitor production processes in real-time, enabling quick responses to any issues that arise.

Moreover, the use of advanced materials, including aluminum and galvanized steel, enhances the durability and corrosion resistance of cable trays. Improved designs and manufacturing techniques also promote eco-friendliness, as manufacturers now focus on sustainability during production.

Conclusion

The importance of cable tray making machines cannot be overstated in today’s infrastructure-focused world. As industries continue to evolve with new technologies and demands, the need for efficient, high-quality cable management solutions will only grow. Cable tray making machines stand at the forefront of this evolution, providing manufacturers with the tools to produce robust and reliable cable trays that support modern electrical systems.

In summary, understanding the significance and advancements of cable tray making machines is essential for those involved in electrical manufacturing and infrastructure development. As technology continues to advance, these machines will play a pivotal role in shaping the future of cable management solutions, ensuring safety and efficiency in electrical installations across various sectors.