The Importance of Purlin Roll Forming Machines for C/Z Sections

In the realm of construction and structural engineering, the use of purlins is crucial for providing support and stability to roofs and walls. Purlins can be classified into C-sections and Z-sections, each serving unique purposes in various applications. The manufacturing of these purlins has evolved over the years, primarily due to advancements in technology surrounding roll forming machines.

The Importance of Purlin Roll Forming Machines for C/Z Sections

One of the key features of a purlin roll forming machine is its versatility. Manufacturers can adjust the machine to produce various sizes of purlins, typically ranging from 100mm to 300mm in depth. This adaptability allows builders and contractors to cater to the specific requirements of their projects, whether it's for residential, commercial, or industrial structures. The level of customization achievable with these machines ensures that clients can receive products that meet their design specifications.

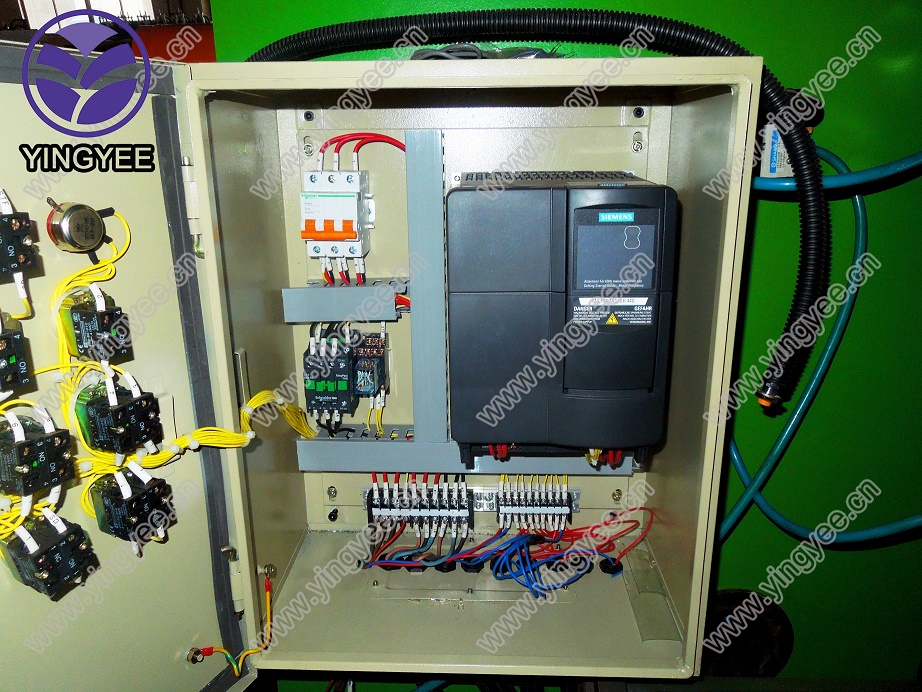

Moreover, purlin roll forming machines operate with a high degree of automation. This modern technology not only increases the speed of production but also enhances the accuracy of the finished products. Automated systems reduce human error during the manufacturing process, leading to more consistent quality in the final purlins. Additionally, many machines come equipped with advanced features such as computerized control panels, allowing operators to easily monitor and adjust the production process.

The benefits of utilizing purlins produced by roll forming machines extend beyond just the manufacturing phase. The lightweight nature of C and Z purlins makes them easier to handle and install, contributing to shorter construction times. Furthermore, the steel used in these purlins typically adheres to high strength standards, making them capable of withstanding various loads and providing a solid support structure.

Cost efficiency is another advantage of using purlin roll forming machines. By producing purlins on-site or in nearby facilities, manufacturers can significantly reduce transportation costs and lead times. The streamlined manufacturing process also minimizes material wastage, thus enhancing overall profitability.

In conclusion, purlin roll forming machines are an invaluable asset in the production of C and Z sections in the construction industry. Their ability to produce high-quality, customized purlins efficiently and cost-effectively makes them a key component in modern construction practices. As the demand for robust and reliable structural elements continues to grow, the role of these machines remains critical in meeting the needs of builders and developers worldwide. Embracing this technology not only enhances productivity but also paves the way for innovative building solutions in a rapidly evolving industry.