The Automatic T Ceiling Production Line Revolutionizing Manufacturing

In recent years, the manufacturing industry has witnessed a paradigm shift towards automation, driven by advancements in technology and the need for increased efficiency

. One significant development in this realm is the automatic T ceiling production line, which has transformed how T-bar ceilings are produced, installed, and maintained.T-bar ceilings, also known as drop ceilings or suspended ceilings, are widely used in commercial and residential spaces for their aesthetic appeal and acoustic properties. Traditionally, the production of T-bar ceilings involved manual labor and was often time-consuming, leading to inconsistencies in quality and increased production costs. However, with the introduction of automatic production lines, manufacturers can now achieve precision, speed, and scalability that were previously unattainable.

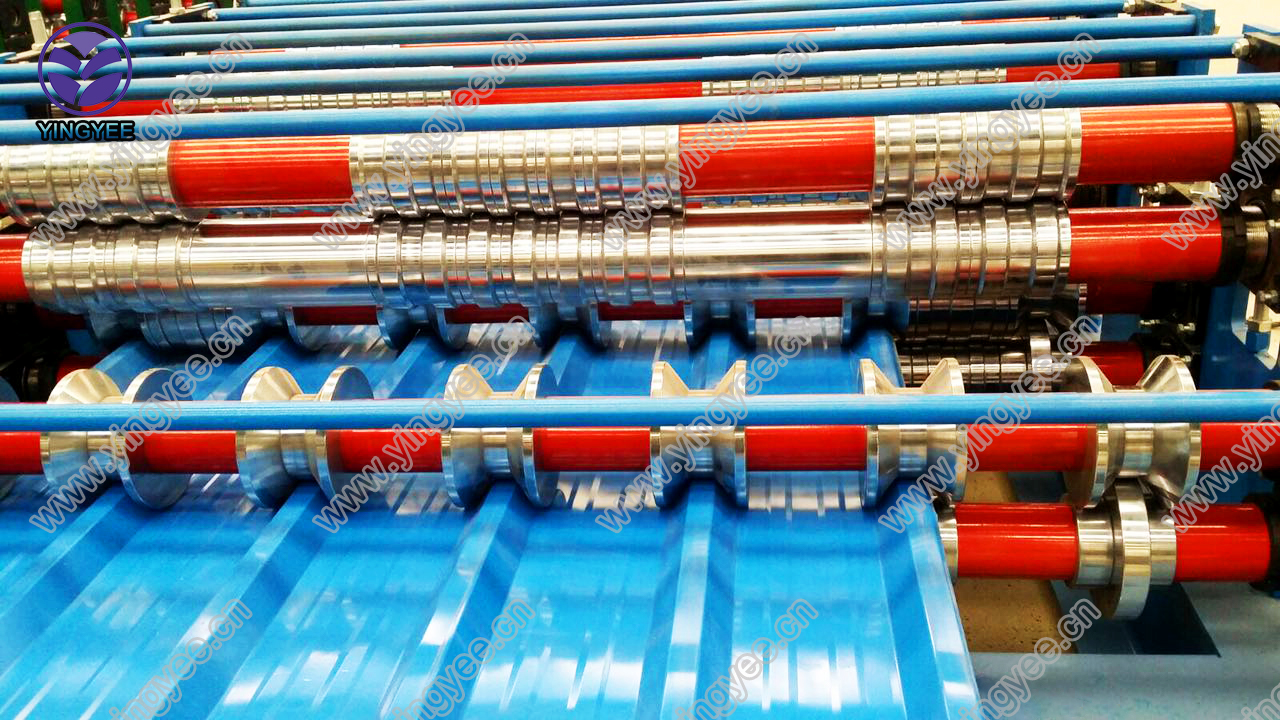

An automatic T ceiling production line integrates various technologies, including robotics, conveyor systems, and advanced software. These components work together to streamline the entire production process, from raw material handling to final product packaging. The automation of repetitive tasks not only reduces labor costs but also minimizes human error, ensuring a consistent product that meets industry standards.

One of the key advantages of an automatic T ceiling production line is its efficiency. With the ability to operate continuously without breaks, these production lines can significantly increase output while reducing lead times. For manufacturers, this means they can respond more quickly to market demands and deliver products faster to their customers. Additionally, the precise calibration of machinery results in minimal waste, making the production process more environmentally friendly.

Moreover, the implementation of an automatic production line can lead to improvements in safety. Automated systems take over hazardous tasks that could potentially injure human workers, thereby creating a safer working environment. Enhanced safety measures not only protect the workforce but also contribute to lower insurance costs for manufacturers.

As businesses strive to remain competitive in a rapidly changing market, the importance of investing in innovative technologies, such as automatic T ceiling production lines, cannot be overstated. This investment not only drives operational efficiency but also fosters product quality and enhances customer satisfaction.

In conclusion, the automatic T ceiling production line represents a significant advancement in manufacturing technology. By embracing automation, manufacturers can improve production efficiency, ensure product quality, and maintain a competitive edge in the ever-evolving market landscape. As we look to the future, it is clear that automation will play a pivotal role in shaping the next generation of manufacturing processes.