The Vertical Large Span Roll Forming Machine Revolutionizing Construction

In the world of modern construction, efficiency and precision are paramount. One technology that has significantly impacted this sector is the vertical large span roll forming machine. This advanced machinery is designed to efficiently produce large spans of metal components, which are essential for various structural applications.

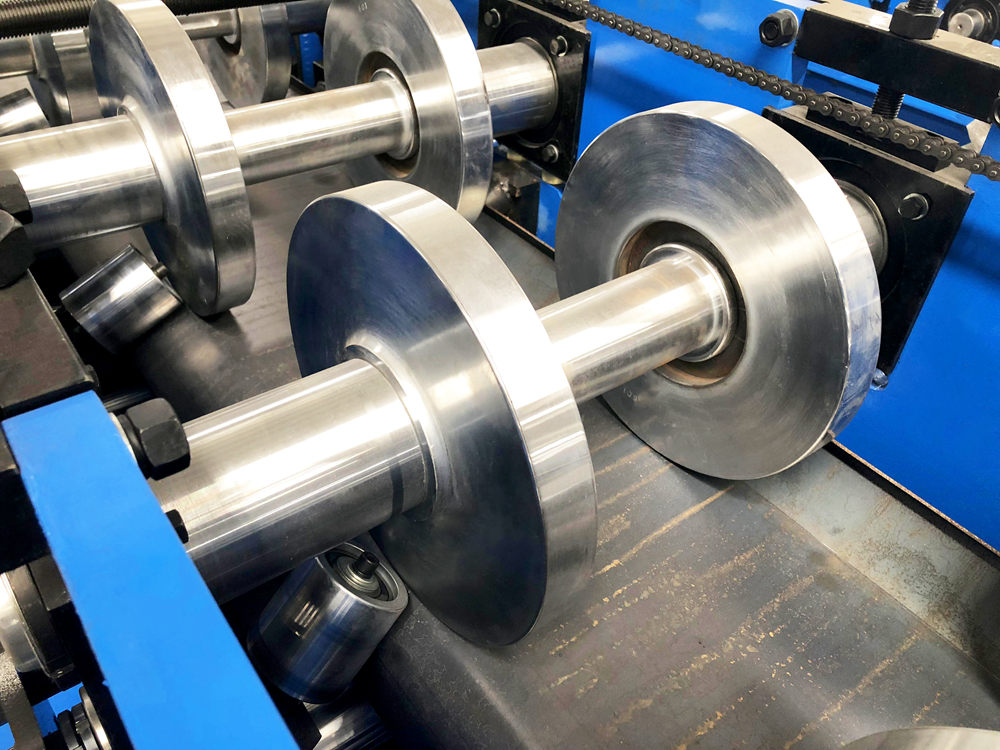

Understanding Roll Forming

Roll forming is a fabrication process that involves feeding a long strip of metal, typically coiled steel or aluminum, through consecutive pairs of rolls. These rolls progressively shape the material into a specific cross-section. The vertical large span roll forming machine enhances this process by allowing for the production of larger and more complex shapes that are often required for commercial and industrial structures.

Key Features and Advantages

The vertical orientation of the machine allows for greater versatility in design and production. Unlike traditional roll forming machines, which operate horizontally, the vertical design accommodates longer components without the need for additional supports or complicated handling systems. This feature not only streamlines the production process but also minimizes the risk of damage to the metal during formation.

Another significant advantage of vertical large span roll forming machines is their efficiency. These machines can produce large quantities of metal profiles in a relatively short amount of time, significantly reducing labor costs and increasing overall productivity. The automation features of modern roll forming machines also facilitate quick changeovers between different product types, enabling manufacturers to respond rapidly to market demand.

Applications in Construction

The applications of vertical large span roll forming machines in construction are vast. They are commonly used to produce roofing sheets, wall panels, and structural sections that form the backbone of buildings, bridges, and industrial facilities. These components are essential in supporting large spans, which are critical for creating open spaces and maximizing usable area in buildings.

In addition to structural elements, roll forming machines are also employed to create architectural features, such as decorative trims and molding. The precision achieved through this technology ensures that these components not only meet structural requirements but also comply with aesthetic standards, enhancing the overall appearance of the construction project.

Sustainability and Cost-Effectiveness

As the construction industry increasingly focuses on sustainability, vertical large span roll forming machines offer a viable solution. The roll forming process minimizes scrap material, making it more environmentally friendly than traditional fabrication methods. Moreover, the ability to create lightweight yet robust profiles can lead to reduced material costs and lower transportation expenses, contributing to a more sustainable construction cycle.

Conclusion

The vertical large span roll forming machine is a game-changing technology in the construction industry. Offering versatility, efficiency, and sustainability, these machines are essential for producing the large components necessary for modern architectural designs. As the demand for innovative and sustainable building solutions continues to grow, so too will the role of advanced manufacturing technologies like the vertical large span roll forming machine. Through automation and precision engineering, these machines not only enhance productivity but also pave the way for the future of construction, ensuring that it meets the challenges of an ever-evolving world.