The Importance of Square and Round Downspout Roll Forming Machines

In the world of construction and building maintenance, efficient drainage systems play a crucial role in protecting structures from water damage. One significant aspect of these systems is the downspout, which directs rainwater away from roofs and foundations. To meet the increasing demand for high-quality downspouts, manufacturers are turning to advanced technologies like square and round downspout roll forming machines.

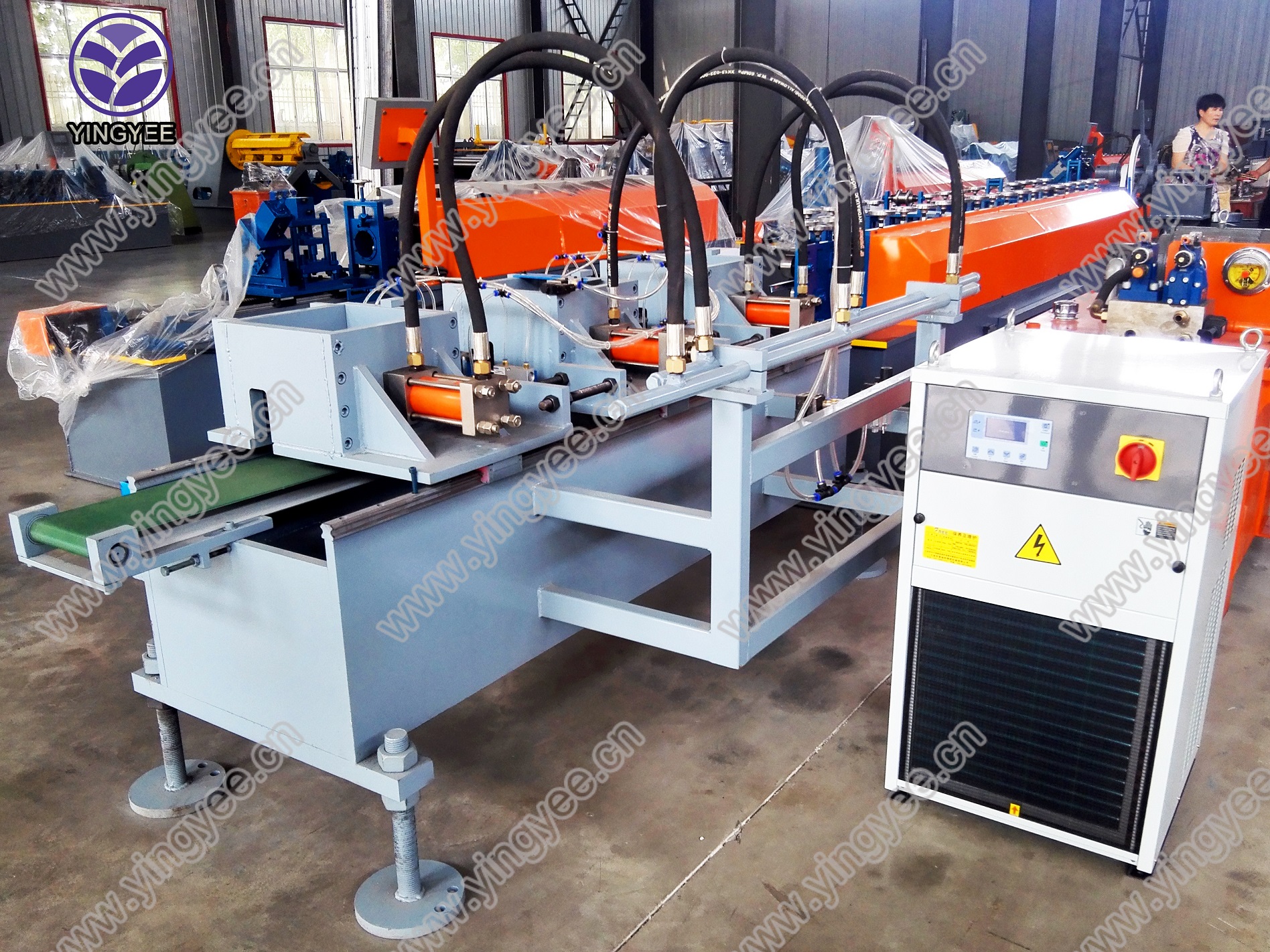

A roll forming machine is a continuous bending process that shapes metal sheets into desired profiles. Square and round downspouts are essential components in rainwater management, and roll forming machines enable manufacturers to produce these parts quickly and efficiently. The primary advantage of using a roll forming machine is its ability to create consistent and uniform products with minimal waste. This not only reduces production costs but also ensures that the downspouts fit seamlessly into existing drainage systems.

The square downspout’s angular design allows it to blend well with modern architectural styles, making it a popular choice for contemporary buildings. Additionally, square downspouts offer enhanced strength and durability compared to their round counterparts. On the other hand, round downspouts are often preferred for traditional designs, as their smooth curves provide an attractive aesthetic. Both shapes can be efficiently produced by dedicated downspout roll forming machines tailored to handle different specifications.

One key feature of advanced roll forming machines is their automation capabilities. With computerized controls, operators can easily adjust settings to produce downspouts of varying sizes and shapes, enhancing production flexibility. This adaptability is further complemented by quick-change tooling systems that allow manufacturers to switch between different profiles with minimal downtime.

Moreover, the integration of quality control systems within roll forming machines ensures that each downspout meets industry standards. This not only guarantees the structural integrity of the product but also boosts customer satisfaction.

In summary, square and round downspout roll forming machines are essential tools in the manufacturing sector, enabling the production of high-quality drainage solutions. By prioritizing efficiency, adaptability, and quality, these machines not only contribute to the durability of buildings but also plays a significant role in effective water management systems. As the construction industry continues to evolve, roll forming technology will undoubtedly remain at the forefront of downspout production.