Understanding PUF Panel Machines Revolutionizing Construction and Insulation

Polyurethane Foam (PUF) panel machines have become increasingly pivotal in modern construction and insulation processes. These machines are designed to manufacture PUF panels, which are widely acclaimed for their excellent thermal insulation properties, lightweight nature, and environmental benefits. This article aims to delve into the significance of PUF panel machines, their functioning, and the applications they cater to in various industries.

What are PUF Panels?

PUF panels consist of polyurethane foam sandwiched between two layers of metal or other materials. The unique structure of these panels provides superior insulation, making them ideal for both industrial and commercial construction. The panels are not only energy-efficient but also cost-effective, reducing heating and cooling costs significantly. As industries become increasingly aware of sustainability, PUF panels offer a reliable solution by enhancing energy efficiency and minimizing environmental impact.

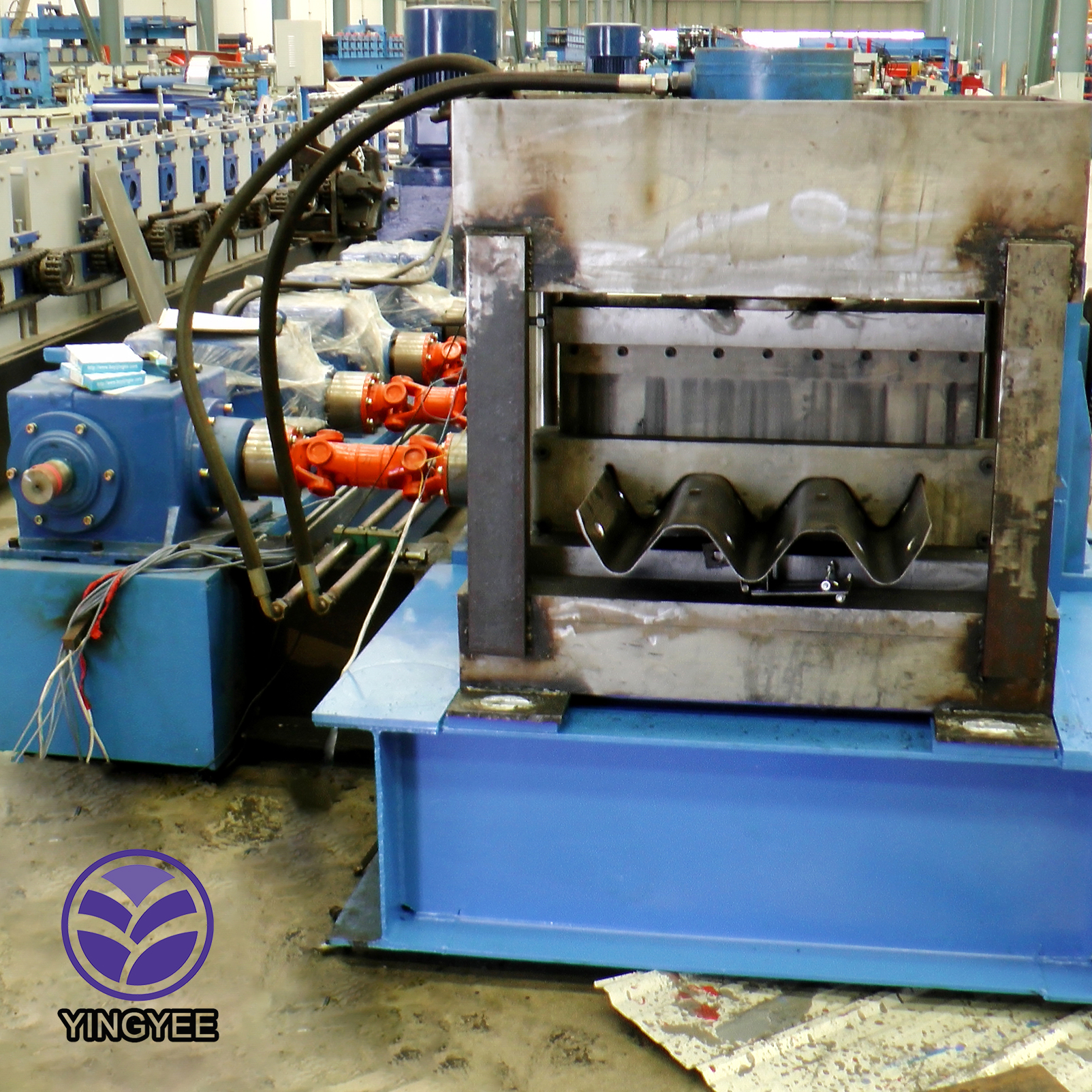

The Functionality of PUF Panel Machines

PUF panel machines operate on a straightforward yet sophisticated technological principle. They are designed to mix two chemical components polyol and isocyanate, which when combined, expand into foam. This foam is then injected between two outer layers of material, forming a rigid, insulated panel. The machines can be equipped with a variety of features, including automatic cutting, high-speed production capabilities, and programmable control systems to ensure precision and efficiency in manufacturing.

The efficiency of PUF panel machines lies in their ability to produce a continuous line of panels, which minimizes waste and maximizes output. Modern machines are designed to produce panels of various thicknesses and sizes, catering to the specific needs of clients across different sectors.

Applications Across Industries

The versatility of PUF panels extends across multiple domains. In construction, they are primarily utilized for pre-engineered buildings, cold storage facilities, and industrial warehouses. The thermal efficiency of PUF panels plays a critical role in maintaining optimal temperatures, especially in refrigeration and cold storage, where temperature control is vital.

Moreover, PUF panels are increasingly used in the manufacturing of insulated roofs and walls, contributing to energy savings in both residential and commercial buildings. Their lightweight nature allows for easy handling and installation, reducing labor costs and time during construction.

In the automotive industry, PUF is used for interior insulation, contributing to greater comfort while enhancing energy efficiency. Their use in HVAC equipment also cannot be overlooked, as PUF panel machines enable the production of insulated ducts that significantly reduce heat loss during air distribution.

Environmental Benefits

One of the standout features of PUF panels is their contribution to sustainability. The use of PUF panels in construction reduces the overall energy consumption of buildings, lowering greenhouse gas emissions. Additionally, due to their insulating properties, buildings constructed with PUF technology can significantly decrease the need for heating and cooling systems, promoting a more sustainable future.

Conclusion

PUF panel machines are at the forefront of an important evolution in construction and insulation technologies. With their ability to produce high-quality panels that offer superior insulation, versatility, and environmental sustainability, these machines are vital for meeting the growing demands of the modern construction industry. As we look toward the future, advancements in PUF technology will undoubtedly continue to play a crucial role in promoting energy efficiency and reducing the environmental footprint of various sectors. Whether it is in building construction, cold storage, or automotive applications, the significance of PUF panel machines is undeniable, paving the way for a more sustainable and efficient future.