Metal Stud and Track Roll Forming Machine for Sale

The construction industry has always sought efficiency, reliability, and productivity. As the demand for innovative building materials continues to grow, metal stud and track roll forming machines have emerged as essential tools for manufacturers in this sector. These machines not only streamline production processes but also enhance the quality of the final products. In this article, we will explore the benefits, features, and considerations when purchasing a metal stud and track roll forming machine.

Understanding Metal Stud and Track Roll Forming Machines

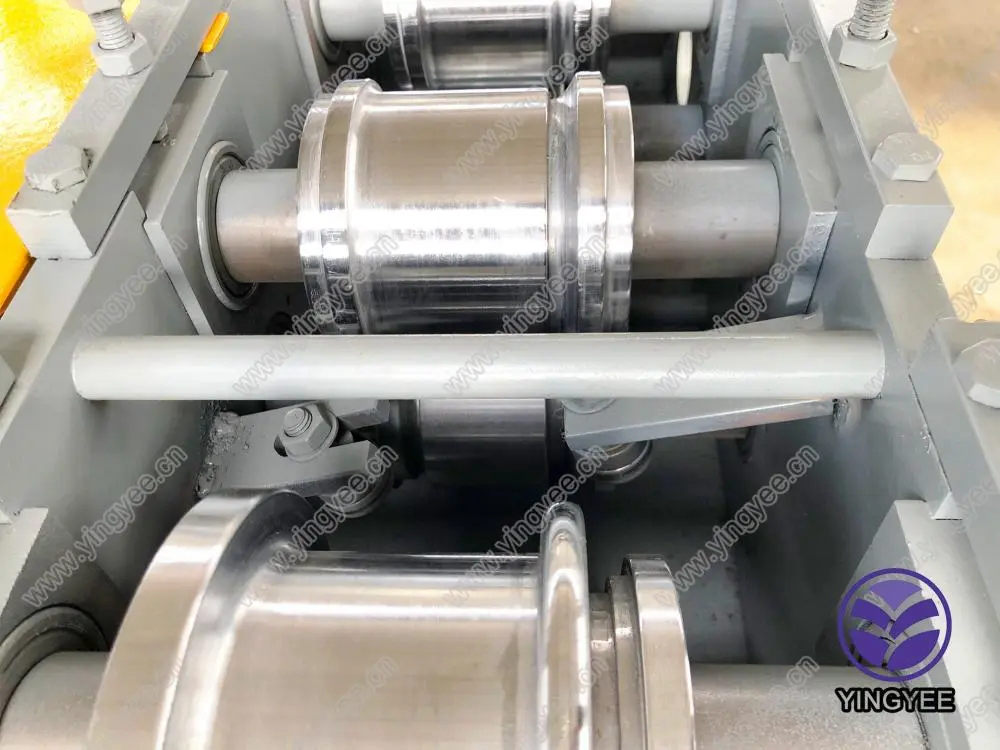

Metal stud and track roll forming machines are specialized equipment designed to produce metal studs and tracks, which are critical components in the construction of walls, ceilings, and other structural elements. The process involves feeding a coil of metal through a series of rollers that gradually shape the metal into the desired profile. The resulting products are lightweight, durable, and resistant to warping, making them ideal for various construction applications.

Key Features of Roll Forming Machines

1. Precision Engineering High-quality roll forming machines are equipped with advanced engineering technology, ensuring that every stud and track is produced with consistent accuracy. This precision is crucial in construction, where tolerance levels can greatly affect structural integrity.

2. Versatility Many modern roll forming machines come with adjustable settings that allow operators to produce different profiles. This versatility enables manufacturers to cater to a wider range of projects and client needs without investing in multiple machines.

3. High Production Speed Automated roll forming machines can operate at impressive speeds, significantly increasing output and reducing labor costs. This efficiency is particularly beneficial for large-scale projects where time is of the essence.

4. Durable Construction Built to withstand the rigors of continuous operation, these machines are constructed from high-quality materials that ensure longevity. Investing in a well-built roll forming machine means less downtime and lower maintenance costs.

5. User-Friendly Controls Modern machines often feature intuitive control panels, allowing operators to quickly adjust settings, monitor production, and troubleshoot issues with ease. This user-friendliness can reduce training time for new employees.

Benefits of Metal Studs and Tracks

The metal studs and tracks produced by roll forming machines offer several advantages over traditional wood framing

- Fire Resistance Metal does not burn, making it a safer choice in buildings where fire hazard is a concern. - Pest Resistance Unlike wood, metal is not susceptible to termites or other pests, which can lead to significant savings in maintenance. - Environmental Sustainability Metal is recyclable, contributing to sustainable building practices. Using metal framing can also qualify projects for green building certifications.

Considerations When Buying a Roll Forming Machine

When considering the purchase of a metal stud and track roll forming machine, there are several critical factors to keep in mind

1. Production Capacity Evaluate your production needs to choose a machine that can meet your demands without overextending your budget.

2. Customization Options Some suppliers offer custom design options to create machines tailored to specific requirements. If unique profiles are part of your business model, explore these options.

3. After-Sales Support A reliable after-sales service can save you time and money in the long run. Ensure that the manufacturer offers comprehensive support, including training, spare parts availability, and technical assistance.

4. Budget Set a realistic budget that considers not just the purchase price, but also operating costs, maintenance, and potential upgrades in the future.

5. Reviews and References Research the manufacturer’s reputation by reading reviews and obtaining references from previous customers. This information can help you gauge the reliability and performance of the machine.

Conclusion

Investing in a metal stud and track roll forming machine can significantly enhance your business’s productivity and product quality. By understanding the machine's features and benefits, along with considering essential purchasing factors, you can make an informed decision that will contribute to your success in the construction industry. As demand for lightweight, strong, and sustainable building materials continues to rise, a roll forming machine could position your company advantageously in this competitive landscape.